Advanced Engineering Mathematics

10th Edition

ISBN: 9780470458365

Author: Erwin Kreyszig

Publisher: Wiley, John & Sons, Incorporated

expand_more

expand_more

format_list_bulleted

Question

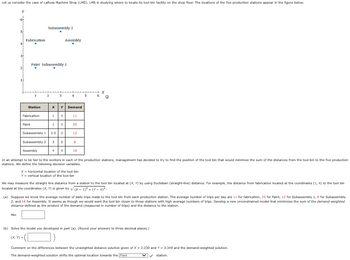

Transcribed Image Text:Let us consider the case of LaRosa Machine Shop (LMS). LMS is studying where to locate its tool bin facility on the shop floor. The locations of the five production stations appear in the figure below.

Y

5

3

Min

2

Fabrication

1

Station

Paint

Paint Subassembly 1

Fabrication

(x, y) =

Subassembly 1

Subassembly 2

Assembly

Subassembly 2

2

1 4

1

3

X Y Demand

3

2.5 2

4

2

Assembly

5

4

4

11

25

12

6

16

X = horizontal location of the tool bin

Y = vertical location of the tool bin

5

In an attempt to be fair to the workers in each of the production stations, management has decided to try to find the position of the tool bin that would minimize the sum of the distances from the tool bin to the five production

stations. We define the following decision variables.

6

e

We may measure the straight line distance from a station to the tool bin located at (X, Y) by using Euclidean (straight-line) distance. For example, the distance from fabrication located at the coordinates (1, 4) to the tool bin

located at the coordinates (X, Y) is given by √(x - 1)² + (Y4)².

(a) Suppose we know the average number of daily trips made to the tool bin from each production station. The average number of trips per day are 11 for fabrication, 25 for Paint, 12 for Subassembly 1, 6 for Subassembly

2, and 16 for Assembly. It seems as though we would want the tool bin closer to those stations with high average numbers of trips. Develop a new unconstrained model that minimizes the sum of the demand-weighted

distance defined as the product of the demand (measured in number of trips) and the distance to the station.

(b) Solve the model you developed in part (a). (Round your answers to three decimal places.)

= (C

Comment on the differences between the unweighted distance solution given of X = 2.230 and Y = 3.349 and the demand-weighted solution.

The demand-weighted solution shifts the optimal location towards the Paint

station.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 26 images

Knowledge Booster

Similar questions

- (intel 1nside - Unit 2 Practice HW 4-1 | Homew x - FlatWorld Course Modules: COLLEGE ALGE X prldknowledge.com/courses/4366/assignments/28898/view/attempt Elementary Analysi. Accounting Work & MLA F B myTCC - Blackboa. O Turnitin ( Dashboard 03 Outlook Courses > Elementary Analysis - Brink > Unit 2 Practice HW 4-1 Full Screen Accessibility Write a function to model the volume of a rectangular prism if the length is 20 cm and the sum of the width and height is 20 cm. V (z) = 400 - x where r is the width of the prism, Check AnswerO You can check your answer 3 moretnebeTore the What is the maximum possible volume of the prism? The maximum volume is cm Check Answer 00arrow_forwardUse North West corner rule to determine the starting solution, hence, an optimal solution to the following transportation problem. To 1 3 4 5 Supply From 1 4 1 100 4 5 7 120 3 5 2 4 8 120 Demand 40 50 70 90 90 6. 2. 3. 2. 2.arrow_forwardpart 3 4arrow_forward

- Given the estimated linear model shown below, complete the following computations. y = 15+ 2x1 + 6x2 + 4x3 a. Compute y when x, = 29, x2 = 32, and x3 = 33. %3D b. Compute y when x, = 23, x2 = 12, and x3 = 14. c. Compute y when x, = 27, x2 = 18, and x3 = 24. d. Compute y when x, = 33, x, = 20, and x3 = 18. а. у 3Darrow_forwardCan someone help me find the questions listed in the screenshot. By using the NorthWest Method and using loop to get to the optimal w.arrow_forwardA chemical manufacturing plant can produce z units of chemical Z given p units of chemical P and r units of chemical R, where: Chemical P costs $100 a unit and chemical R costs $400 a unit. The company wants to produce as many units of chemical Z as possible with a total budget of $80,000. 2= 100p0.8.0.2 A) How many units each chemical (P and R) should be "purchased" to maximize production of chemical Z subject to the budgetary constraint? Units of chemical P, p = Units of chemical R, r = B) What is the maximum number of units of chemical Z under the given budgetary conditions? (Round your answer to the nearest whole unit.) Max production, z= unitsarrow_forward

- Find the production schedule for the technology matrix and demand vector given below: 0.4 1.7 3 A 0.2 0.1 0.7 D = 0.1 0.1 0.1 X = ... 出arrow_forward3x 6. 7. 5+ 8. 64x 9. 3x 16x 24x 10. Play the Tower of Hanoi and determine the minimum mumber of moves required to transfer the disks from the peg to the third peg for each of the following situations. a. You start with only one disk. b. You start with two disks. c. You start with three disks. (Note: You can use a stack of various size coins to simulate the puzzle, or you can use one of the many websites that provide a simulation of the puzzle. Ex. https://www.mathisfun.convgames/towerofhanoi.html) d. You start with four disks. e. You start with fi ve disks. I. You start with n disks.arrow_forward1arrow_forward

- Find the production schedule for the technology matrix and demand vector given below:arrow_forwardThe table below lists six points on the production possibilities frontier for grain and cars. From this information you can conclude that production is inefficient if this economy produces: Point Production of grain (tons) Production of cars (cars) A 27 23 9. 18 10 F 10 O 4 tons of grain and 26 cars. 8 tons of grain and 10 cars. 2 tons of grain and 27 cars. O 6 tons of grain and 17 cars. 30arrow_forward.1 Certify X gin in a new win... ing.com/Portal/Lesson/lesson_certify Week 8 - FIN-341- Question 1 of 11, Step 1 of 1 Answer X Week 1- BIO-165-5... - Save & Exit Certify Lesson: 6.1 Solving Systems of Linear E... Ⓒ2022 Hawkes Learning X My Citation list 6/2 x W C My books Doxy Leona Doxy Kelsey Selecting an option will display any text boxes needed to complete your answer. How can derivative X 0/11 Correct Use any convenient method to solve the following system of equations. If the system is dependent, express the solution set in terms of one of the variables. Leave all fractional answers in fraction form. = -1 x + 2y y-32= 131 -4x - 6y + 6z = 30 Consumers and Th X 4 Digital Content | Up... O Only One Solution O Inconsistent System O Dependent System b Success Confirmat Textbook Solutions REBECCA BOONE Tables Keypad Keyboard Shortcuts Submit Answerarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education

Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY

Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Advanced Engineering Mathematics

Advanced Math

ISBN:9780470458365

Author:Erwin Kreyszig

Publisher:Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:9780073397924

Author:Steven C. Chapra Dr., Raymond P. Canale

Publisher:McGraw-Hill Education

Introductory Mathematics for Engineering Applicat...

Advanced Math

ISBN:9781118141809

Author:Nathan Klingbeil

Publisher:WILEY

Mathematics For Machine Technology

Advanced Math

ISBN:9781337798310

Author:Peterson, John.

Publisher:Cengage Learning,