Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

Leaching of Oil from Soybeans in a Single Stage. Repeat Example 31.2-1 for single-stage leaching of oil from soybeans. The 100 kg of soybeans contains 22 wt % oil and the solvent feed is 80 kg of solvent containing 3 wt % soybean oil.

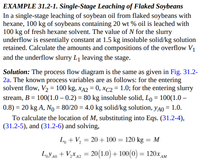

Transcribed Image Text:EXAMPLE 31.2-1. Single-Stage Leaching of Flaked Soybeans

In a single-stage leaching of soybean oil from flaked soybeans with

hexane, 100 kg of soybeans containing 20 wt % oil is leached with

100 kg of fresh hexane solvent. The value of N for the slurry

underflow is essentially constant at 1.5 kg insoluble solid/kg solution

retained. Calculate the amounts and compositions of the overflow V1

and the underflow slurry L1 leaving the stage.

Solution: The process flow diagram is the same as given in Fig. 31.2-

2a. The known process variables are as follows: for the entering

solvent flow, V2 = 100 kg, x42 = 0, XC2 = 1.0; for the entering slurry

stream, B = 100(1.0 – 0.2) = 80 kg insoluble solid, Lo = 100(1.0 –

%3D

0.8) = 20 kg A, No = 80/20 = 4.0 kg solid/kg solution, yA0 = 1.0.

To calculate the location of M, substituting into Eqs. (31.2-4),

(31.2-5), and (31.2-6) and solving,

L, + V, = 20 + 100 = 120 kg = M

%3D

LY A0 + V,*42 = 20(1.0) + 100(0) = 120x AM

Transcribed Image Text:Lo

3-

N

N vs. YA

V2-

M

N vs. XA

0.5

1.0

YA, XA

Figure 31.2-3. Graphical solution of single-stage leaching for Example 31.2-

1.

Hence, XAM = 0.167.

B = N,L, = 4.0(20) = 80 = N,(120)

N = 0.667

The point M is plotted in Fig. 31.2-3 along with V2 and Lo The

vertical tie line is drawn locating L1 and Vị in equilibrium with each

other. Then, N1 = 1.5, yA1 = 0.167, xA1 = 0.167. Substituting into

Eqs. (31.2-4) and (31.2-6), and solving or using the lever-arm rule, L1

= 53.3 kg and V = 66.7 kg.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- In microfiltration, why is an operation that combines constant-flux and constant-pressure operations used?arrow_forwardWhy must solvent be accounted for in calculating the enthalpic contribution to folding? What is the entropic contribution that solvent makes to folding? Can you please explain your answer??arrow_forwardIllustrate the preparation of porous carbon materials using sugarcane biomassarrow_forward

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The