Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

thumb_up100%

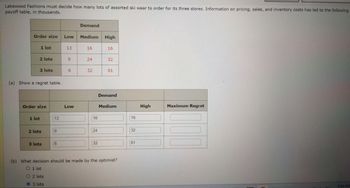

Transcribed Image Text:Lakewood Fashions must decide how many lots of assorted ski wear to order for its three stores. Information on pricing, sales, and inventory costs has led to the following

payoff table, in thousands.

Order size

1 lot

2 lots

3 lots

(a) Show a regret table.

Order size

1 lot

2 lots

3 lots

13

9

6

Low

13

9

6

Low

Demand

Medium

16

24

32

16

24

32

High

16

32

61

Demand

Medium

(b) What decision should be made by the optimist?

O 1 lot

O2 lots

3 lots

16

32

61

High

Maximum Regret

2:06 PM

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- 3. Price should reflect the organization's a, policy b. vision &, strategy d. All of the above.arrow_forwardI need help pleasearrow_forwardPT Cahaya Pintar Utama (PT. CPU) makes special lights that are popular in new homes. PT. CPU demand for two popular lights (VX-1234 and BX-1010) to be the following over the next 12 weeks, as listed in Table 2. Table 2. Demand data Week 1 2 3 4 5 6 7 8 9 10 11 12 VX-1234 82 94 78 96 105 90 86 75 88 98 110 100 BX-1010 250 280 301 312 290 300 275 286 310 334 350 318 A key component in both lights is a light socket that the bulb is screwed into in the base fixture. Each light has one of these sockets. Given the following information (Table 3). Table 3. Information VX-1234 BX-1010 Light Socket On Hand 185 425 620 Lot Size 325 600 500 (purchase quantity) Lead time (week) 1 1 3 Safety Stock 0 10 20 On Order 50 (week 5) 150 (week 4) - Questions: Develop and complete the material requirement planning to plan the production of…arrow_forward

- If the company in #8 uses exponential smoothing (smoothing factor = .6) and the forecast for the year is the figure they use for EOQ calculations, calculate the EOQ using the following information: The cost of ordering and carrying cost % are the same as #7 Cost of ordering: $25 Carrying costs: 45% Starting with 2018, Forecast the 2020 demand using exponential smoothing and then use that forecast as the annual demand. year sales 2017 1,000,000 2018 1,200,000 2019 2,000,000 2020arrow_forward1. Explain 4P marketing of adjustment buckles of mask. 2. Explain SWOT marketing of adjustment buckles of mask. 3. Explain advantages of adjustment buckles of mask.arrow_forwardk of PDF : https://docdro.id/psUSO2n https://docdro.id/KV8USNQ question : 1/ According to Weele, the items that we measure determines the role of the purchasing function. List these roles, and show the mapping. 2/ According to Simpson and et.al, why should we measure the performance of our suppliers? 3/ According to Simpson and et. al, what are the characteristics of our suppliers should we measure? List these down in terms of evaluative criteria and its details.arrow_forward

- Dont give me handwritten answer thankuarrow_forwardPLEASE ANSWER BOTH QUESTIONS without excel a) Using a weighted moving average with three periods, determine the demand for period 13. Use 3, 2, and 1 for the weights of the most recent, second most recent, and third most recent periods, respectively b) Find the MAD, MSE and MAPEarrow_forwardPlease answer D & E.arrow_forward

- Please complete the sup part: e,f and g. 1.B&H needs to decide how to manage its inventory of cameras. The demand for cameras at B&H is 200 cameras per week. Each time that B&H places an order for a new shipment of cameras, it must pay $80 in fixed processing fees. A camera costs B&H $60 to purchase. The cost for B&H to hold a camera in its store for one week is $4. Assume that the lead time for the delivery of a camera is 0 weeks.a. Suppose that B&H places orders for cameras in quantities of 50 cameras at a time and places a new order for cameras each time that it runs out. Draw a graph showing the number of cameras that B&H has on-hand in inventory at each point in time up until the time when it places its fourth-order. Label the points in time at which B&H places a new order. Assume that B&H places its first order for 50 cameras on day 0.b. Suppose again that B&H places orders for 50 cameras at a time. What will be B&H’s average holding…arrow_forwardQ2) Clancy's Motors has the following demand to meet for custom manufactured fuel injector parts. The holding cost for that item is $2 per month and each setup costs $80. Lead time is 0 months. Calculate the planned order releases using: (a) the EOQ technique, and (b) the POQ technique. And What are the costs of each plan, including the holding cost of any inventory left over after month 7? What technique performance is better. Month 1 2 3 4 5 6 7 Requirement 400 150 200 150 100 150 250 Answer: (a) The monthly holding cost = $2/month Average monthly demand = ??? units The EOQ = ??? units Total inventory held = ??? units Setup costs = $??? Holding cost = $???? Total cost = $???? (b) POQ Interval = ?.??, round to # month. Total inventory held = ? units Setup costs = $??? Holding cost = $? Total cost = $???arrow_forward12. Determine the planned purchases for January (a) at retail and (b) at cost for the lingerie department when the seasonal merchandise plan indicates the following planned figures: Round to the nearest dollar. Sales $88,000 Markdowns 8% BOM Stock $81,000 EOM Stock $66,000 Markup 49%arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.