Supply chain partner – a global network

Coca-Cola is a global company that operates at a local level. This means that there are currently around 225 bottling partners worldwide. The supply chain begins with the procurement of raw materials, which in the case of Coca-Cola also includes agricultural products (e.g. sugar cane or fruit) and water. The most important ingredients such as water and sugar are sourced locally, with the partners being able to choose only the type of sugar used. In Europe, mainly beet sugar is used, in Asia cane sugar and in America sugar from corn syrup. One of the first steps in Coca-Cola’s supply chain is the production of the concentrate, which is mixed with water, sugar and carbon dioxide by the bottling plants. The concentrate itself is produced at other plants. According to legend, the secret

recipe is kept in a safe in Atlanta. The legend also states that never more than two people should have access to it and know the exact recipe. After mixing, the bottlers package, market and distribute the finished beverages to grocery stores, restaurants, cinemas,etc. Therefore, the management of supplier relationships and the continuous monitoring of suppliers is of great importance to the company. New technologies support an efficient supply chain

With the help of technology such as warehouse automation, the company wants to continuously improve its

cooperation with its partners and the 160,000 orders per day, create more transparency and reduce costs using block chain technology. Coca-Cola already uses an IT platform specifically for the communication of the bottlers. For example, if a partner has a bottleneck, it can purchase the quantities from another partner. With block chain, Coca-Cola expects to reduce the duration of order-reconciliation from 50 days to just a few days. An inter-organizational, transparent distributed ledger will give real-time insights into the transactions made by all the different bottlers on the network, which generatesover $21 billion in revenue per year.

Another example of innovative technologies at Coca Cola is the production of bottles from plastic waste from beaches and the sea. Nearly 300 sample bottles were produced using 25 percent recycled marine plastic. The sample bottles were developed to demonstrate the potential of improved recycling technologies. These innovative processes make it possible to turn used plastic of any quality back into high-quality plastic. In the process, the components of the plastic (polymers) are broken down and impurities in the material are removed. It is then possible to reassemble the individual components (monomers) so that the resulting material is as good as new. This means that inferior plastics, which were previously often incinerated or deposited in landfills, can thus remain in the material cycle and be used again for packaging food. This increases the amount of recyclable material in the cycle. This in turn reduces the amount of new PET and thus fossil materials needed to produce new packaging and could therefore mean strong changes for the Coca Cola supply chain.Closing Thoughts Coca-Cola has long been a global player. Accordingly, the company is continuously optimizing and modernizing its supply chain. Due to the high sales of the soft drink, the supply chain focuses on the management of partner companies. Here,smooth communication with the partners and the subsequent smooth distribution to the points of sale play a major role.

Coca-Cola is and remains a very popular soft drink. For this reason, it is even more astonishing that the company has managed to keep its exact recipe secret for decades and thus also the exact steps of the Coca-Cola supply chain. Due to the secret recipe, the supply chain is certainly a bit mysterious – and amazing.

With reference to the case study, propose several steps Coca-Cola may take to identify value drivers, align its operations strategy, and satisfy the demands of the specific markets it serves. Use practical examples to support your answer.

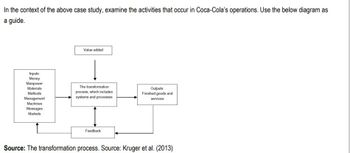

In the context of the above case study, examine the activities that occur in Coca-Cola’s operations. Use the below diagram as a guide.

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

- Suppose an organisation that manufactures personal protective equipment for the South African market is located in China. This South African organisation provides personal protective equipment as an additional product offering; however, it is not core to its operations. Using the practical context provided and the scenario above, illustrate a supply chain depicting the movement of these goods.Note: You are to use the illustration of a generic supply chain provided to you as a starting point. You are not to replicate that generic supply chain as your final answer. Using evidence of application to the scenario provided.arrow_forwardplease answer correctly in a detailed manner.arrow_forwardMITIGATING SUPPLYCHAIN RISKS TO IMPROVE COMPETITIVENESS With the increasing sophistication of supply chains, organizations are finding it difficult to attain a constant flow of supplies across all network and turning to some form of collaboration across different tiers. Sourcing has become the order of the day despite the logistical challenges involved. The outbreak of the war between Israel and Palestine, Ukraine and Russia has accelerated widespread increases in global commodity prices making it difficult for purchasers to attain their goals. The wars represent a unique shock that has a major impact on production, distribution and availability of materials. In order to ensure continued supply and/or delivery supply chains need to effectively coordinate and consolidate supply bases across different actors to mitigate shortages. Q.1. Basing on your own assessment of the current situation globally, would you recommend organizations and/or supply chains to undertake supplier…arrow_forward

- MITIGATING SUPPLYCHAIN RISKS TO IMPROVE COMPETITIVENESS With the increasing sophistication of supply chains, organizations are finding it difficult to attain a constant flow of supplies across all network and turning to some form of collaboration across different tiers. Sourcing has become the order of the day despite the logistical challenges involved. The outbreak of the war between Israel and Palestine, Ukraine and Russia has accelerated widespread increases in global commodity prices making it difficult for purchasers to attain their goals. The wars represent a unique shock that has a major impact on production, distribution and availability of materials. In order to ensure continued supply and/or delivery supply chains need to effectively coordinate and consolidate supply bases across different actors to mitigate shortages. Q.1 Evaluate the influence of global risks on the achievement of key purchasing objectives and/or outcomes in the entire supply chain.arrow_forwardOf the following, which is a major drawback to using production contracts as part of a vertically integrated supply system? A. Supply chain efficiency B. Capturing additional margins C. A means of addressing "holdup" in a market D. Limited decision-making ability of the producerarrow_forward(Adapted from Portillo, 2009) Recall the case study on designing a resilient global supply chain discussed in Section 8.6. The five main criteria considered are as follows: GP: Gross profit LT: Lead time DF: Demand fulfillment RD: Risk of disruption SF: Strategic factor (a) Using a rating method, the Director of supply chain, assigned a score from 1 to 10 (1 being the least important and 10 being the most important) for the five criteria as shown in Table 8.10. Determine the criteria weights using the rating method. (b) Suppose the Director of supply chain ranks the criteria from most important to least important as follows: (Most important) GP, DF, LT, SF, RD (Least important) Using Borda count, determine the criteria weights.arrow_forward

- Explain how these supply chain activities are involved in getting a product from conception to delivery: Upstream Downstream Internal How does enterprise software enable a business to use industry-proven best practices? Explain the bull-whip effect on a supply chain and how it can be avoided. Describe the difference between push-based supply models and pull-based supply models.arrow_forwardIf a quota of 40 towels is placed on imported towels that sell for $5 each, what is the total revenue to the government?arrow_forwardWhat is the bullwhip effect and how does it relate to lack off coordination in the supply chain?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.