Consider again managing inventory for product 101, provided by Supplier A. Recall that

demand for 101 is approximately d = 200 units per week. You pay a purchase cost p = $500

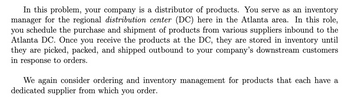

per unit and value your inventory at r = $550 per unit. You estimate your inventory carry-

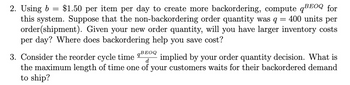

ing cost rate at r = 18% per year; storing one item of product 101 in your DC requires an

equivalent rent (storage cost) of s = $10 per unit per year.

Use truckload shipping for your orders of product 101; recall then that your total fixed

cost (k + F ) = $900 for any order of size no greater than Q = 700 units. You estimate a

total lead time (order processing plus transit time) of 12 days for these shipments.

To reduce your logistics costs, you decide that it might be worthwhile to backorder some

of the customer demand you face each cycle. When backordering, you will delay your out-

bound shipping of some of your customers’ orders.

b = $3 per unit backordered per day as a loss-of-goodwill charge that will result from

your customers. Suppose you fill orders 7 days a week to your customers. On average,

how many days per week (fractional) will you backorder demand? If you instead wanted

to backorder demand one day out of every seven, what is the implied backordering cost

b′ per item per day?

Step by stepSolved in 2 steps

- At a recent manufacturing workshop, XYZ, Incorporated explained that demand for disposable masks increase rapidly in March 2020 when quarantine mandates first took effect. At the time, retailers could only place a single order to cover demands through the end of the summer. A certain retailer purchased disposal masks from a supplier at a cost of $20 per unit and sold them for $30 per unit. By the end of summer, demand for masks subsided considerably and all masks that weren't sold during the summer could be sold at a discounted price of $18 per unit. The retailer estimated that demand between March and August would be Normally distributed with mu = 10,000 and sigma = 1525 units With, supply chains becoming more stable since March 2020, the retailer is currently in the process of establishing a contract with a disposable mask supplier. The supplier has agreed to sell masks to the retailer for $18 per unit and will make deliveries any time the supplier places an order for a cost of $100…arrow_forwardBarbara Flynn is in charge of maintaining hospital supplies at General Hospital. During the past year, the mean lead time demand for bandage BX-5 was 70 (and was normally distributed). Furthermore, the standard deviation for BX-5 was 7. Ms. Flynn would like to maintain a 90% service level. Refer to the standard normal table for z-values. a) What safety stock level do you recommend for BX-5? Safety stock = units (round your response to the nearest whole number).arrow_forwardA coffee shop consumes 350 lbs of coffee per week at a steady rate. The coffee shop buys coffee from a supplier at the cost of $10 per lb, and ordering cost of $5 per order. The supplier takes 8 days to deliver an order (assume that 1 week = 7 days). What should be the reorder point (in pounds) for the coffee shop (i.e., at what level of inventory it should place an order with the supplier).arrow_forward

- In a Q system, the demand rate for strawberry ice cream is normally distributed, with an average of 295 pints per week. The lead time is 6 weeks. The standard deviation of weekly demand is 16 pints. Refer to the standard normal table for z-values. a. The standard deviation of demand during the 6-week lead time is 39 pints. (Enter your response rounded to the nearest whole number.) b. The average demand during the 6-week lead time is 1770 pints. (Enter your response as an integer.) c. The reorder point that results in a cycle-service level of 96 percent is pints. (Enter your response rounded to the nearest whole number.)arrow_forwardAndy's Job Shop buys two parts (Tegdiws and Widgets) for use in its production system from two different suppliers. The parts are needed throughout the entire 52-week year to assemble Uediracs for sale. Tegdiws are used at a relatively constant rate but the use of Widgets vary with demand. Andy wants to improve his inventory management system and use either a "P" system or a "Q" system. What are the advantages and disadvantages of each system in this application and what information is needed to choose between them?arrow_forwardIn an ABC system based on revenue, C items individually make the lowest annual revenue contribution. TRUE FALSEarrow_forward

- 7arrow_forwardYou are a newsvendor selling the San Pedro Times every morning. Before you get to work, you go to the printer and buy the day's paper for $0.25 a copy. You sell a copy of the San Pedro Times for $1.30. Daily demand is distributed normally with mean = 260 and standard deviation = 46. At the end of each morning, any leftover copies are worthless and they go to a recycle bin. a. How many copies of the San Pedro Times should you buy each morning? Note: Use Excel's NORM.S.INV() function to find the z value. Round your z value and service level to 2 decimal places and final answer to the nearest whole number. Optimal order quantity b. Based on a, what is the probability that you will run out of stock? Note: Round your answer to the nearest whole percent. Probability %arrow_forwardDavid's Delicatessen flies in Hebrew National salamis regularly to satisfy a growing demand for the salamis in Silicon Valley. The owner, David Gold, estimates that the demand for the salamis is pretty steady at 175 per month. The salamis cost Gold $1.85 each. The fixed cost of calling his brother in New York and having the salamis flown in is $200. It takes three weeks to receive an order. Gold's accountant, Irving Wu, recommendsan annual cost of capital of 22 percent, a cost of shelf space of 3 percent of the value of the item, and a cost of 2 percent of the value for taxes and insurance. How many salamis should Gold have on hand when he phones his brother to send another shipment?arrow_forward

- Peter Sagan is in charge of maintaining hospital supplies at Champs Hospital. During the past year the mean weekly demand for a special type of tubing was 186 packages of this tubing with a standard deviation of 13 packages of tubing. The lead time for receiving this tubing from the supplier is 1.5 weeks. Peter would like to maintain a 95% service level and places an order for 750 packages every time an order is placed. d) If the weekly demand is 186 and there is a 1.5 week lead time - what is the reorder point (99% service level)? e) If the carrying cost per year is $0.50/unit/year - what is the additional cost associate with the 99% service level compared to 95% service level (i.e. cost of safety stock at 99% level - cost of safety stock at 95% service level)?arrow_forwardUniversity of Florida football programs areprinted 1 week prior to each home game. Attendance averages90,000 screaming and loyal Gators fans, of whom two-thirdsusually buy the program, following a normal distribution, for$4 each. Unsold programs are sent to a recycling center thatpays only 10 cents per program. The standard deviation is5,000 programs, and the cost to print each program is $1.a) What is the cost of underestimating demand for eachprogram?b) What is the overage cost per program?c) How many programs should be ordered per game?d) What is the stockout risk for this order size?arrow_forwardThe following data give monthly Demband >1300 units Ordenng cost Holding lo st to Q - $ 15 pe oder $2/ units peo year 464 Lead time 4 days %3D wha t is the tolal annua / vanable inventory Cost Cie total annus! total aroual ordening) © $968 $ 8 ® $484 D $ I436 14520arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.