Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

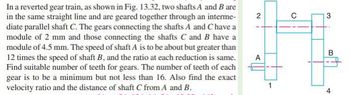

Transcribed Image Text:In a reverted gear train, as shown in Fig. 13.32, two shafts A and B are

in the same straight line and are geared together through an interme-

diate parallel shaft C. The gears connecting the shafts A and Chave a

module of 2 mm and those connecting the shafts C and B have a

module of 4.5 mm. The speed of shaft A is to be about but greater than

12 times the speed of shaft B, and the ratio at each reduction is same.

Find suitable number of teeth for gears. The number of teeth of each

gear is to be a minimum but not less than 16. Also find the exact

velocity ratio and the distance of shaft C from A and B.

2

1

A

C

B

st

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- PLZ ANSWER ASAP................................ : ) ENSURE THAT THE ANS MATCHES THE GIVEN ANS IN THE IMAGE!arrow_forwardA set of gears is used to reduce the speed from an electric motor to a shaft driving a grocery checkout conveyor, depicted below. The gear on the motor shaft is a 10-pitch pinion, has 18 teeth, and drives at 1200 rpm clockwise. The driven gear has 72 teeth. The motor has failed and is to be replaced with the only motor available, a 600 rpm motor with an 8-pitch pinion. Specify the set of commercially available 20⁰ spur gears, by number of teeth (N3and N4), that would result in the same conveyor speed and can be used without modification to the mounting (the center distance must not change). Find the number of teeth N3 on the pinion (drive) gear (teeth): Find the number of teeth N4 on the driven gear (teeth):arrow_forwardi need the answer quicklyarrow_forward

- Gears Two 20-pitch, 14.5°, full-depth, involute spur gears are used on a machine shop lathe. The pinion has 16 teeth and the gear has 70 teeth. Determine the following: Q5.a The centre distance Q5.b The contact ratio Q5.c Whether interference is a problem Q5.d A centre distance that reduces backlash from a vendor value of 0.4/Pd to an AGMA recommended value of 0.1/Pdarrow_forwardplease help solvearrow_forward5.3 Please help. Provide Free Body Diagram, labeled with appropriate quantities to better understand. Also solve. Thank you.arrow_forward

- Question 1 An epicyclic gear train, as shown in Fig. 1, has a sun wheel S of 30 teeth and two planet wheels P-P of 50 teeth. The planet wheels mesh with the internal teeth of a fixed annulus A. The driving shaft carrying the sun-wheel S, transmits 4 kW at 300 r.p.m. The driven shaft is connected to an arm which carries the planet wheels. 1.1 Tabulate a table of motion for the given epicyclic gear train. 1.2 Determine the number of teeth in gear A, assume module is the same on all the gears. 1.3 Determine the speed of the arm or the driven shaft. 1.4 Determine the torque of the sun. 1.5 Determine the torque of the arm if the overall efficiency is 95 %. Arm S A a. 1 Figure 1: An epicyclic gear trainarrow_forwardPlease answer in proper unitsarrow_forwardi need the answer quicklyarrow_forward

- 6. 5 3 Arm 6. 2 Arm Arm 2 3 1 Bearing Given N2 = 30, N3 = 25, N4 =45, N5 = 40, N6 = 200 W2 = 240 rpm ccw, warm = 120 rpm cw, T2 = 12 ft-lb Show your work. Answers without work will not be accepted a. Identify the gear sets. b. Determine the velocity gear train ratio and the angular velocity of gear 6. c. Determine the torque gear train ratio and output torque of gear 6.arrow_forward1. To avoid the problem of interference in a pair of spur gears using a 20° pressure angle, specify the minimum number of teeth allowed on the pinion (Np.act) for each of the following gear ratios, and the corresponding maximum number of teeth on meshing gear (NG,act). Assume full depth tooth. a. 1.25 to 1 b. 1.6 to 1 c. 2.5 to 1 d. 3.2 to 1 2. Repeat problem 1 for helical gears with normal pressure angle of 20° and helix angle of 30°.arrow_forwardplease helparrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY