Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

why is the external load not shown in the free body diagram of limk 2 and 4?

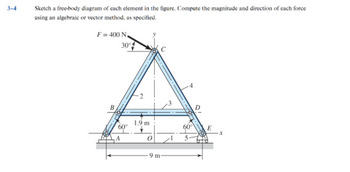

Transcribed Image Text:3-4

Sketch a free-body diagram of each element in the figure. Compute the magnitude and direction of each force

using an algebraic or vector method, as specified.

F=400 N.

30°

60⁰

A

1.9 m

0

9 m-

60° E

5

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 18 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

What I am struggling to understand from this problem. (1) Why does the external load not show up in the FBD of links 4 and 2? (2) why do points B and D not have a force in y-direction?

Thank you.

Solution

by Bartleby Expert

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

What I am struggling to understand from this problem. (1) Why does the external load not show up in the FBD of links 4 and 2? (2) why do points B and D not have a force in y-direction?

Thank you.

Solution

by Bartleby Expert

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Oil-tempered wire of 5 mm diameter is used to make a helical compression spring shown in Figure 3. The spring index would be, C=12. The spring will be operated inside a bore, therefore buckling is insignificant. Both ends are left plain. The spring free length is 100 mm. An axial force of 75 N should deflect the spring by 10 mm. a) Determine the spring rate, k. b) Determine the minimum hole diameter for the spring to operate. c) Determine the total number of coils needed. d) Determine the solid length, Ls. e) What force, F's is needed to compress the spring to its solid length? ) Determine the largost shear stross in the spring due to the force Fs. Fs Lo Figure 3arrow_forwardOil-tempered wire of 5 mm diameter is used to make a helical compression spring shown in Figure3. The spring index would be, C = 12. The spring will be operated inside a bore, therefore bucklingis insignificant. Both ends are left plain. The spring free length is 100 mm. An axial force of 75 Nshould deflect the spring by 10 mm.arrow_forwardThe crank of jib crane model J-06T is fixed at one end and hinged to a pivot pin. The crank is 300 in and 5” in diameter. Assuming carbon –alloy steel (E = 29,000 ksi) What is the safe working compressive load on the crank at FS = 4?arrow_forward

- . A helical compression spring is to be made of oil-tempered wire of 4 mm diameter with a spring index of C=10. The spring is to operate inside a hole, so buckling is not a problem, and the ends can be left plain. The free length of the spring should be 80 mm. A force of 50 N should deflect the spring 15 mm. (Take: G= 77 GPa) 1- Determine the minimum hole diameter for the spring to operate in. 2-Determine the solid length. 3-Determine a static factor of safety based on the yielding of the spring if it is compressed to its solid length.arrow_forwardA shaft acting as simple supported beam is having a static deflection of 2.72 mm under a flywheel. The critical speed in rad/sec will bearrow_forwardQ3. You should draw a three DoF (Degree of freedom) eight link (n=8) mechanism with revolute joints. You should verify DoF mechanism using mobility formulations.arrow_forward

- K1 = (60/2)+3=33arrow_forward(a) A hollow C15 steel(oy= 235.4Mpa, oy=425Mpa shaft transmits 15kW at 250rpm as shown in figure Task 1a. It is supported on two bearings 750mm apart. A 500mm pulley whose weight is 1000N is keyed to the shaft at a distance of 100mm to the left of left bearing. A pinion having 75teeth and 4mm module is mounted at 150mm to the left of right bearing. The pulley is driven by a belt downward at an angle of 60°to the horizontal and towards the observer. The pinion drives a gear placed directly over it. Tension ratio=3 and diameter ratio=2. Determine the diameter of the shaft with ASME code. Assume the shaft rotates clockwise when viewed from right bearing and $=20⁰ (T₁+T₂) sin 60+ W, 60⁰ (T₁+T₂.) cos 60 Driven T₁+T₂ Pulley A Figure Task 1aarrow_forwardPlease only do if you have knowledge and 100% sure and please only handwritten I need or skiparrow_forward

- A steel wire 2 mm diameter is held between fixed bearings. The wire weighs 0.241N/m and the flexural stiffness is 0.157 N.m2. If the highest critical speed is 5000 RPM with the length of the wire of 1.0 m, what is the approximate no. of mode (your answer should be a whole number).arrow_forwardDesign a helical extension spring to hold the roller follower against the cam as shown in Figure 1. The maximum extension of spring (ymax = 8.3 mm), the dynamic load varies from 250 N at the low position and 400 N at the high position . The diameter of the circular cam is 200 mm rotates off center with an eccentricity of 25 mm and operates the roller follower that is carried by the arm. The speed of the cam is 200 rpm. Design choices, (C= 10 ), shear modulus G= 80 GPa , A227 as a material for the spring, Wire endurance limit Sew = 310 MPa, factor of safety for spring body is 1.5. The spring ends are standard. a. Check the initial tension in the spring and compart it with minimum load. b. Determine the physical parameters of the spring. c. Check the surging of spring. 200 mm -100 mm- - - Spring 25 mm wwarrow_forwardA narrow V-belt (wedge belt) transmits power from an internal combustion engine operating at 700 rpm to the shaft of a dough mixer (medium duty) operating at 50 rpm. The internal combustion engine develops a nominal power of 50 kW and the dough mixer operates for no more than 8 hours per day. Which of the following belts can be used for this application? Hint: First determine the design load by using an appropriate service factor from page F12 in Appendix H in the Design Manual. SPC only SPB or SPC SPA or SPB SPB onlyarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY