Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

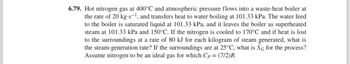

Transcribed Image Text:6.79. Hot nitrogen gas at 400°C and atmospheric pressure flows into a waste-heat boiler at the rate of 20 kg·s⁻¹, and transfers heat to water boiling at 101.33 kPa. The water feed to the boiler is saturated liquid at 101.33 kPa, and it leaves the boiler as superheated steam at 101.33 kPa and 150°C. If the nitrogen is cooled to 170°C and if heat is lost to the surroundings at a rate of 80 kJ for each kilogram of steam generated, what is the steam-generation rate? If the surroundings are at 25°C, what is S_G for the process? Assume nitrogen to be an ideal gas for which C_P = (7/2)R.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 3 images

Knowledge Booster

Similar questions

- calculate the heat required to raise the temperature of 1 mol of methane from 260 to 600 °c in steady flow process at a pressure sufficient low that methane may be considered an ideal gasarrow_forwardA a. Liquid sodium, flowing at 100kg/s, enters a heat exchanger at 450°C and exits at 350°C. The Cp of sodium is 1.25 kJ/kg C. Liquid water enters at 5000kPa and 20°C and leaves as saturated gas at 5000kPa. The heat exchanger is adiabatic. Determine the mass flowrate of the water (kg/s) b. 2 kg of air are compressed from 210kPa to 2000kPa while maintaining the temperature constant at 30°C. Calculate the required heat transfer in kJ. Assume Ideal Gas Rer=287 1/kgkarrow_forwardA fuel oil is burned with air in a boiler furnace. The combustion produces 650 kW of thermal energy, of which 55% is transferred as heat to a boiler tubes that pass through the furnace. The combustion products pass from the furnace to a stack at 650°C. Water enters the boiler tubes as a liquid at 20 °C and leaves the tubes as saturated steam at 20 bar absolute. a. Define the system. What type of energy balance is needed?arrow_forward

- Ethylene at 30 bar and 100°C passes through a throttling valve and heat exchanger, emerging at 20 bar and 150°C. Assuming that ethylene obeys the Peng-Robinson equation of state, compute the flow of heat (J/mol) into the heat exchanger per mole of ethylene.arrow_forwardA heat exchanger is used to transfer heat from a steam stream to a chlorine gas stream. 100 kg of steam at 1 bar and 200 °C enters the heat exchanger and leaves the exchanger as saturated steam at 1 bar. Chlorine gas enters the exchanger at 1 bar and 48.0 °C and leaves the exchanger at 141.0 °C. Assume the heat exchanger is adiabatic. What is the specific enthalpy of the inlet steam stream? (Use liquid water at 0.01 °C as a reference state.) Ĥ și= kJ/kg What is the specific enthalpy of the outlet steam stream? (Use the same reference state.) 50= kJ/kg What is the specific enthalpy of the inlet chlorine gas stream? (Use chlorine gas at 1 bar and 48.0 °C as a reference state.) Ĥci= kJ/mol What is the specific enthalpy of the outlet chlorine gas stream? (Use chlorine gas at 1 bar and 48.0 °C as a reference state.) ÊĤ co= kJ/mol How many moles of chlorine gas enter the heat exchanger? nc = mol What is the ratio of the volume of inlet steam to the volume of inlet chlorine gas? Use the ideal…arrow_forwardConsider an engine operating on the ideal Otto cycle with a compression ratio of 9.5. At the beginning of the compression process, the air is at 100 kPa and 25°C. During the constant-volume heat-addition process, 850 kJ/kg of heat is transferred to air from a source at 1800K and waste heat is rejected to the surroundings at 290 K. Accounting for the variation of specific heats of air with temperature, determine (a) the thermal efficiency of this cycle, (b) the exergy destruction associated with the heat-addition process, (c) the exergy destruction associated with the heat-rejection process, and (d) the second-law efficiency of this cycle.arrow_forward

- I need assistance with this question I'm confusedarrow_forwardHandwritten Only.arrow_forward2-Steam initially at 10 bar and 0.25 dryness fraction (i.e quality=85%.). Expands down to P₂= 3.5 bar According to the hyperbolic law. PV=Constant, Determine. 1. The final of the steam. 2- The change of temperature of the steam. 3. The work done kg during the change. 4 The change in internal energy. 5- The amount of heat suppliedarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The