Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

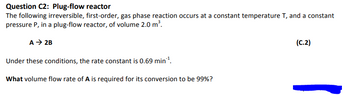

Transcribed Image Text:Question C2: Plug-flow reactor

The following irreversible, first-order, gas phase reaction occurs at a constant temperature T, and a constant

pressure P, in a plug-flow reactor, of volume 2.0 m³.

A → 2B

Under these conditions, the rate constant is 0.69 min¹.

What volume flow rate of A is required for its conversion to be 99%?

(C.2)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

Hi, I used this equation:

- k*V/v0 = -(1+e)*ln(1-XA) - e*xA

And got the answer 0.00279 m^3/sec.

Could you explain to me why the equation I've used is wrong as I've noticed it's slightly different to the one you have used.

Many Thanks

Solution

by Bartleby Expert

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

Hi, I used this equation:

- k*V/v0 = -(1+e)*ln(1-XA) - e*xA

And got the answer 0.00279 m^3/sec.

Could you explain to me why the equation I've used is wrong as I've noticed it's slightly different to the one you have used.

Many Thanks

Solution

by Bartleby Expert

Knowledge Booster

Similar questions

- Problem 4 The reversible, exothermic, liquid phase, homogeneous reaction A ₹R is being carried out in two ideal CSTRs. Both reactors operate at 150°C. The molar flow rate of A entering the first CSTR is 55,000 mol/h, the concentration of A in this stream is 6.5 mol/L, and the concentration of R is zero. The fractional conversion of A in the outlet stream from the second CSTR is 0.75. The fractional conversion is based on the molar flow rate entering the first CSTR. The reaction is first order in both directions. The rate constant for the forward reaction is 1.3 h-¹ and the equilibrium constant based on concentration at 150°C is 10.0. If the volume of the second CSTR is 10,000 L, what is the required volume of the first CSTR?arrow_forwardQUESTION IN IMAGEEarrow_forwardc32 plz answer allarrow_forward

- please work out all the partsarrow_forwardplease quickly i just need the answer thansks !!arrow_forward1. The reaction A → B is to be carried out isothermally in a continuous-flow reactor. The entering volumetric flow rate (v.) is 8 L/h. For a constant volumetric flow rate v = Do, then FA CAVO Also, CAO FAO/vo. Pure species A enters into the reactor at a rate of 4 mol/h. Calculate both the CSTR and PFR volumes necessary to consume 99% of species A (i.e., CA = 0.01CAo) assuming the reaction rate -гA is a. -TAKA with kA = 0.05 mol/L.h b. rA KACA with kA = 0.0001 s¨¹ C. -TA KA(CA)² with kA = 300 L/mol.h 2. Repeat parts a, b, and c above to calculate the time necessary to consume 99.9% of species A in a 1,000 L constant-volume batch reactor with CA。 = 0.5 mol/L.arrow_forward

- note: this is about chemical reaction engineering conversion and reactor sizing. show all the necessary steps and solutions. correct answer only pls. thank you. type the answer.arrow_forwardFor the gas-phase reaction A = 2B operated at 1.0 bar: Initially, the reactor contains only A, at 1.0 mol. a. Prove that the reaction coordinate (moles of A consumed) equals the following: (see attactched image) b. Make a plot of the reaction coordinate versus temperature between 200 and 400 K for exothermic reaction conditions, making use of the van’t Hoff Equation. Data: Ka = 5.0 at 298 K, ΔHrxn0 = -50.0 kJ mol-1. Neglect the ΔCp term. c. Repeat Part b for endothermic conditions. Ka = 5.0 at 298 K, ΔHrxn0 = +50.0 kJ mol-1. Neglect the ΔCp term. d. If the reaction described in part b (i.e., exothermic conditions) were operated in a simple batch reactor, would the reaction mixture’s temperature increase, decrease, or remain constant as the reaction progressed? To maximize conversion, would you recommend that heat be added to, or removed from, the reactor?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The