Concept explainers

-

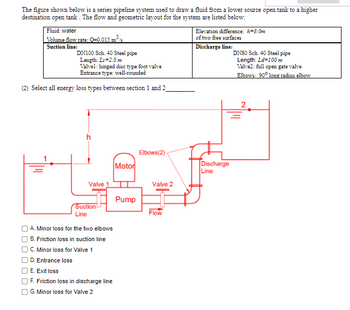

The figure shown below is a series pipeline system used to draw a fluid from a lower source open tank to a higher destination open tank . The flow and geometric layout for the system are listed below:

Fluid: water

Volume flow rate: Q=0.015 m3/s

Elevation difference: h=8.0m

of two free surfaces

Suction line:

DN100 Sch. 40 Steel pipe

Length: Ls=2.0 m

Valve1: hinged disc type foot valve

Entrance type: well-rounded

Discharge line:

DN80 Sch. 40 Steel pipe

Length: Ld=100 m

Valve2: full open gate valve

Elbows: 90ο long radius elbow

(2) Select all energy loss types between section 1 and 2_________

A. Minor loss for the two elbows

B. Friction loss in suction line

C. Minor loss for Valve 1

D. Entrance loss

E. Exit loss

F. Friction loss in discharge line

G. Minor loss for Valve 2

Step by stepSolved in 2 steps

- A pumping station wet well operates between 540- and 550-ft elevation. The pump curve is deϐined by the following points: 80 ft at zero ϐlow, 78 ft at 200 gpm, 65 ft at 800 gpm, and 50 ft at 1200 gpm. The pump discharge contains an equivalent of 50 ft of 6-in. pipe. The discharge pipe is 120-ft long and terminates at a splitter box, elevation 570. Using C=100, plot the pump curve and the corrected pump curve. Plot the pump discharge curves at each wet well elevation and for C=100 and C=140. What is the pump ϐlow at the low and high wet well elevations for newand old pipe?arrow_forwardSolve correctly please. I will ratearrow_forward2. As shown in Fig. 2, the hydraulic pump suctioned oil from a large oil tank, the flow rate q =150L/min, Kinematic viscosity of oil v=34x106 m/s, density of oil p=900kg/m³, the diameter of suction pipe d=60mm. and assuming the minor resistance coefficient of elbow of oil suction pipe =0.2, the pressure loss of the filter at suction port Ap = 0.0178MP.. if the vacuum degree at the inlet of pump is not bigger than 0.04Mpa, calculate the Oil absorption height H (without considering the pressure losses along straight line between the surface and filter) Figure 2arrow_forward

- The figure shown below is a series pipeline system used to draw a fluid from a lower source open tank to a higher destination open tank . The flow and geometric layout for the system are listed below: Fluid: water Volume flow rate: Q=0.015 m3/s Elevation difference: h=8.0m of two free surfaces Suction line: DN100 Sch. 40 Steel pipe Length: Ls=2.0 m Valve1: hinged disc type foot valve Entrance type: well-rounded Discharge line: DN80 Sch. 40 Steel pipe Length: Ld=100 m Valve2: full open gate valve Elbows: 90ο long radius elbow (1) Select the simplified general energy equations for section 1 and 2_________ A. B. C. D.arrow_forward.com/c/Mjc5MTg3Nj12NzEz/a/M]950TUXNTUWMTE2/details Problem 3: A large pressurized tank filled with air discharges into the atmosphere. The flow path is a short and frictionless smooth pipe connected to a discharge nozzle. Find a) the flow rate of air and b) pressure in the pipe for the given data. Ignore all frictional losses, including head losses at the entrance to the pipe, at the bend, and at the nozzle. Prank (kPa): 110.0 Dpipe (m): 0.040 P (kPa): 101 atm Nozzle (m): 0.015 Tatm (C): 20 Airarrow_forwardFor a 6.25-inch Model 4075 pump operated at 1160 rpm, if 450 GPM of water is to be delivered, what will be the estimated pump head in ft? HEAD IN FEET 30 25 0 0 0 10 O 6 ft 7.25" (184mm) 20 7.00" (178mm). 6.75" (171mm). 6.50" (165mm)] 15 6.25" (159mm). 5 O 16 ft O 20 ft O 12 ft aco® L/SEC 5 OT 10 Model 4075 FI & CI Series 15 -6-6 ⁰ dº 20 ANA 888 778 25 REQUIRED NPSH do 1160 RPM November 1, 2010 K ・dº- [M 90 do 30 8800 81 1HP(.75KW) DeJ kin do 60% 35 do 50 Curve no. 2175 Min. Imp. Dia. 6.25" Size 5 x 4 x 7.0 40 45 3HP(2.2KW), 2HP(1 5KW) 5HP(1 1KW)> CURVES BASED ON CLEAR WATER WITH SPECIFIC GRAVITY OF 1.0 L 75 150 225 300 375 450 525 600 675 FLOW IN GALLONS PER MINUTE NOWONG FEET 15 12 7 6 2 1 NPSH 758 50 5 HEAD IN METERS 45 586888 KPO 60 40 20 10 LO HEAD IN KILOPASCALSarrow_forward

- 20arrow_forwardThe oil is pumped from a reservoir tank to the automobile tank. The volume flow rate of oil is 3,2 cm/s. The pipe diameter is 5 mm. The oil discharges through a 0.8-mm nozzle in a tank. The pressure in the tank is 95 kPa. The total head loss in the system is 1.1 m. If the pump has an efficiency of 58,18%, determine the power [W] needed by the pump. (NOTE: Po = 673 kg/m) 05 m 95 kPa 100 kPa Pumparrow_forwardCarefully solve[Check the Unit Properly,Use exact Formula] 1) A fan delivers 1200 m3/min of air through a rectangular duct, 1 m x 1.5 m. How much air power is required if the static pressure is 150 mm WG and the air density is 1.18 kg/m3.arrow_forward

- 5arrow_forwardDisplacement (c): 0.2 in3/revShank diameter (d) = 0.625 in.Piston diameter (D) = 1.5 in.Rotation speed (n): 1725 RPMPressure (P): 600 PSIStroke (L) = 18in. a) Calculate the theoretical flow rate of the pump in in3/min and US GPM.Theoretical flow (Q) = Theoretical displacement (C) x Speed of revolution (n)Theoretical flow (Q) = 0.2 in3/rev x 1725 rpmTheoretical flow (Q) = 345 in3/min = 1.49 US GPM b) Calculate the cylinder output speed in in/s.Cylinder output speed (VS) = Piston side flow (Q) / Piston area (Ap)Cylinder output speed (VS) = (Displacement x Speed of revolution) / Piston area (Ap)Cylinder output speed (VS) = (0.2 in3/rev x 1725 RPM) / 1.77 in2Cylinder output speed (VS) = (0.2 in3/rev x 1725 RPM) / 1.77 in2Cylinder output speed (VS) = 196.02in/s = 196.02 / 60s = 3.20 in/s Questions: c) Knowing the output velocity (ram speed), calculate the rod side flow in GPM when the ram is extending. d) Calculate the piston exit time in seconds. e) Calculate the piston entry time in…arrow_forward### Develop a conclusion of a piping design report for the choice of a pump, based on the calculated parameters of flow Q = 10 l/s, power of 10kw taking into account that the head of 60 mca adopted was higher than that calculated for safety, and that the pump was chosen through the WebCAPS catalogue of the company GRUNDFOS. The pump chosen was the GRUNDFOS CR 32-3 A-F-A-E-HQQEarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY