Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

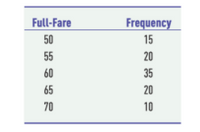

FlyUs Airlines is unhappy with the number of empty seats on

its New York to Philadelphia flight. To remedy the problem,

the airline is offering a special discounted rate of $89 instead

of the normal $169, but only for 7-day advance purchases

and for a limited number of seats per flight. The aircraft

flown from NY to Philly holds 100 passengers. Last month’s

distribution of full-fare passengers is shown below. How

many seats should FlyUs reserve for full-fare passengers?

Transcribed Image Text:Full-Fare

Frequency

50

15

55

20

60

35

65

20

70

10

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Chris Sandvig Irrigation, Inc., has summarized theprice list from four potential suppliers of an underground controlvalve. See the accompanying table on the next page. Annual usageis 2,400 valves; order cost is $10 per order; and annual inventory holding costs are $3 .33 per unit.Which vendor should be selected and what order quantity isbest if Sandvig Irrigation wants to minimize total cost?arrow_forwardProblem 15-2 (Algo) Determine which shipping alternative would be most economical to ship 100 boxes of parts when each box has a price of $200 and holding costs are 30 percent of price, given this shipping information: overnight, $300, two-day, $260, six-day, $180. (Round your intermediate calculations to 2 decimal places.) Two day O Overnight O Six dayarrow_forwardquestion #2 Same problem statement: Weekly demand for DVD-Rs at a retailer is normally distributed with a mean of 1,000 boxes and a standard deviation of 150. Currently, the store places orders to the supplier, with a reorder point of 4,200 boxes. The order quantity to the supplier is fixed at 5,000 boxes. Replenishment lead time is 4 weeks, fixed order cost per order is $100, each box costs the retailer $10, and the inventory holding cost is 25% per year. If the retailer wants to achieve a 99% service level (use the z-value with one decimal, as in Table 13.4 on page 400 of the textbook), what should be the safety stock value? Numeric Response 772.8 SHARE f5 f6 4- f7 ♫+ fg fil W f12. insert prt sc delete home @ 0 end 1:23 PM 11/15/2022 pg Larrow_forward

- Greek Circle manufacturing makes and sells specialty hubcaps for the retail automobile after market. GC’s forecast for its wire-wheel hubcap is 2,000 units next year, with an average daily demand of 4 units. However, the production process is most efficient at 8 units per day. If the Setup costs are $10, the Carrying Costs are $0.50 per unit per year, what is the Optimum Production Order Quantity? So the company produces 8 per day but uses only 4 per day. The company wants to solve the optimum number of units per order. (Note. The plant schedules production of this hubcap only as needed, during the 250 days per year the shop operates). If the Setup costs are $10, the Carrying Costs are $0.50 per unit per year, what is the Optimum Production Order Quantity.arrow_forward2. (Quantity Discount) County Hospital orders syringes from a hospital supply firm. The hospital expects to use 40,000 per year. The cost to order and have the syringes delivered is $800. The annual carrying cost is $1.90 per syringe because of security and theft. The hospital supply firm offers the following quantity discount pricing schedule. Qty 0-9,999 10,000-19,999 20,000-29,999 30,000-39,999 40,000-49,999 50,000+ Price $ 3.40 $ 3.20 $ 3.00 $ 2.80 $ 2.60 $ 2.40 What is best order quantity for syringes that minimize total cost?arrow_forwardquestion #5 Same problem statement: Weekly demand for DVD-Rs at a retailer is normally distributed with a mean of 1,000 boxes and a standard deviation of 150. Currently, the store places orders to the supplier, with a reorder point of 4,200 boxes. The order quantity to the supplier is fixed at 5,000 boxes. Replenishment lead time is 4 weeks, fixed order cost per order is $100, each box costs the retailer $10, and the inventory holding cost is 25% per year. Under the current order quantity of 5,000 boxes and current reorder point of 4,200 boxes, what would be the order-up-to level S that the retailer should use as a baseline to calculate how much inventory to order when conducting a periodic review? Numeric Response 1500 f4 ***** LA f5 40 % f6 4- 0 C + & 7 < Prev. 門 fg KAA * 8 5 of 5 DII hp f10 DDI 9 Next fi W f12. insert prt sc + 11 ( ← delete backspace home num lock end 1:24 PM 11/15/2022 pg uparrow_forward

- Problem 13-16 The McDonald's fast-food restaurant on campus sells an average of 4,800 quarter-pound hamburgers each week. Hamburger patties are resupplied twice a week, and on average the store has 465 pounds of hamburger in stock. Assume that the hamburger patties cost $3 a pound and there are 52 weeks in a year. a. What is the inventory turnover for the hamburger patties? (Round your answer to 2 decimal places.) Inventory turnover per year b. On average, how many days of supply are on hand? (Do not round intermediate calculations. Round your answer to 2 decimal places.) Average days of supplyarrow_forwardCompany B is a retailer of mobile phones in Australia that works 250 days in a year. The manager is determining a minimum-cost inventory plan for an upcoming phone to be launched in the market. She has collected the following information: • Annual demand: 1000 phones • Phone cost: $1,214 each • Phone RRP: $1,349 each • Net weight: 163 g each • Tare weight: 277 g each • Annual inventory holding cost: 15% • Cost per order to replenish inventory: $75 • Annual in-transit holding cost: 10% • Freight rate: $8.10 per kg • Time to process order for freight: 1 days • Freight transit time: 3 days Solve this problem using a non-linear programming (NLP) model to determine the followings:d. The total cost for holding the inventory e. The total cost for transportation f. The total cost for holding the phones during transit g. The total cost for this inventory plan h. The number of orders i. Ordering point j. The profit from this inventory planarrow_forwardHow would these factors affect an EOQ analysis?(1) The use of just-in-time procedures.arrow_forward

- Question: What level of safety stock should be maintained? Please show the solution. Thank youarrow_forwardquestion #3 Same problem statement: Weekly demand for DVD-Rs at a retailer is normally distributed with a mean of 1,000 boxes and a standard deviation of 150. Currently, the store places orders to the supplier, with a reorder point of 4,200 boxes. The order quantity to the supplier is fixed at 5,000 boxes. Replenishment lead time is 4 weeks, fixed order cost per order is $100, each box costs the retailer $10, and the inventory holding cost is 25% per year. With a safety stock of 300 boxes, what is the approximate service level (round to two decimals)? Numeric Response 84.13 * f5 10 f6 0 4- ♫+ fg C fil W f12. insert prt sc + 11 Ə ← delete backspace home num lock 4x D end 1:23 PM 11/15/2022 pg uparrow_forwardConduct a mathematical analysis of the Wilson EOQ model and its practical applicability in real-world scenarios.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.