Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

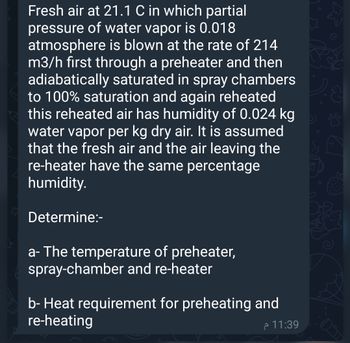

Transcribed Image Text:Fresh air at 21.1 C in which partial

pressure of water vapor is 0.018

atmosphere is blown at the rate of 214

m3/h first through a preheater and then

adiabatically saturated in spray chambers

to 100% saturation and again reheated

this reheated air has humidity of 0.024 kg

water vapor per kg dry air. It is assumed

that the fresh air and the air leaving the

re-heater have the same percentage

humidity.

Determine:-

a- The temperature of preheater,

spray-chamber and re-heater

b- Heat requirement for preheating and

re-heating

11:39 م

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- How high a relative humidity must a 35°C air have in order to obtain saturated airat 18°C by evaporative cooling? solve with complete diagramarrow_forwardMoist air, which contains 2.30 mol% Hz0, at 25°Cand 100 kPa is to be dehumidified so thatduring its passage through a large cold room, ice formation can be avoided on the chilling coils in the room. Two suggestions have been offered: (1) Cooling the moist air atconstant pressure (2) Compressing the moist air atconstant temperature 1. Whatpressure should the moist air in process (2) reach for the process to obtain 60% percentremovalof water?arrow_forwardPlz do it fast I have to submit now. Plz do it in 30minarrow_forward

- Pls. Anwer my quistion.. Thank you! Air enters an air-conditioning system that uses refrigerant-134a at 30OC and 70 percent relative humidity at a rate of 4 m3 /min. The refrigerant enters the cooling section at 700 kPa with a quality of 20 percent and leaves as saturated vapor. The air is cooled to 20OC at a pressure of 1 atm. Determine (a) the rate of dehumidification in kg/min (b) the refrigerating Effect in KJ/min (c) the mass flow rate of the refrigerant in kg/minarrow_forwardWhat is the temperature entering the cooling sectionwhen 25 kW of heat are removed and the air exits at 15 deg C, a relative humidity of 30% and a volumetric flowrate of 0.7 m^3/s?arrow_forwardI need the answer as soon as possiblearrow_forward

- Question attachedarrow_forwardQUESTION 1 Water at 60°C leaving a condenser at the rate of 22.5kg/s is sprayed into a natural-draught cooling tower and leaves it at 27°C. Air enters the tower at 1.013bar, 13°C and 50% relative humidity and leaves it at 38°C, saturated. Take Cp for the superheated vapour as 1.86 kJ/kgK. Calculate: 1.1. the air flow rate required in m/s; 1.2. the make-up water required in kg/s.arrow_forwardA volumetric flow rate of 3750 m'h of outside air at 39 °C dry bulb and 26 °C wet bulb temperatures is to mixed with 8250 mh of return air at 25 °C and 50% rgative humidity before entering a cooling coil in an conditioning device. The mixture leaving the coil.at0% relative humidity is then supplied to the space sensible heat ratio of the conditioned space is 0.75) Sketch the process on the psychrometric chart and t the followings: a) The dry bulb temperature of the supply air. b) The cooling coil capacity, kW. c) The apparatus dew point and supply air dew.point temperatures. d) The sensible and latent heat loads of the space. e) The bypass factor of the cooling coil. The rate at which moisture is removed from air.arrow_forward

- 5. Dry winter atmospheric air at latm, 8°C and 50% bumidity enter an HVAC system at a rate of 10m/hr, where it is isobarically conditioned to 21°C, 50% humidity. A water line supplies saturated water vapour. Determine heating or cooling rate required to accomplish this process. Also determine the rate wat which water must be supplied in the system in KW. Take heat of vaporization of water to be 2539.9kJ/kg. Note IKJ/S = 1KWarrow_forwardWhat is amount of entropy generation "kJ/K" during the condensation of a 2.8 kg of a pure substance "latent heat of vaporization of 1024.04 kJ/kg.K, T 55 C" and the surroundings are at 30 C? satarrow_forwardMoist air at 21 C° DBT and 15 C° WBT and standard atmospheric pressure is humid by water spray. If for each one kg of dry air passing through the duct 0.002 kg of wa 100 C° is injected and totally evaporated. Draw the psychometric and schematic figu process and calculate for the air leaving the a- The moisture content. spray chamber: b- The enthalpy c- Dry bulb temperature.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY