Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Find the original cross sectional area anf original length from the given information about a tensile test done on a specimen

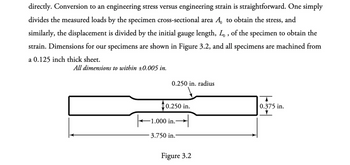

Transcribed Image Text:directly. Conversion to an engineering stress versus engineering strain is straightforward. One simply

divides the measured loads by the specimen cross-sectional area A to obtain the stress, and

similarly, the displacement is divided by the initial gauge length, L, of the specimen to obtain the

strain. Dimensions for our specimens are shown in Figure 3.2, and all specimens are machined from

a 0.125 inch thick sheet.

All dimensions to within ±0.005 in.

0.250 in. radius

0.250 in.

1.000 in.-

3.750 in.

Figure 3.2

0.375 in.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- In tensile test a plain carbon steel specimen has a (40mm) gauge length and the Final area (A final) of specimen after tensile test was 264.327. The load which caused fracture was (122.5 KN). After fracture, the final length was 47.516mm Choose the correct answers for the following sentences: Initial area (A final) of specimen * O568.254 O 313.994 325.256 152.368arrow_forwardMENG364 MANUFACTURING TECHNOLOGY PLEASE Put the letter as it is and I will put the student number later Please solve it very quickly ?? ?? ??arrow_forwardwhy do we physically mark gauge length on the samples before the test even though the machine is measuring displacement for us.(Tensile Testing Machine) What is the effect of rate of loading, what is a soft start what is its importance?arrow_forward

- in a Torsion test done. the following data were collected: the radius of the specimen was 3mm and the gauge length was 76.2mm. During the elastic zone: T1=0. 01N.m. 81=14.760, 12-17.13N.m, and 02 36.910, The modulus of rigidity G will be equal to: Select one O a 44.283 GPa. O b. 26.522 GPa. O C 462.91 MPa. O d. 12.94 GPa.arrow_forwardWhat does a tensile test show?arrow_forwardHow can I solve for the %0.2 offset strain and the calculated stress? Original diameter : 6mm Original length : 30mm Fracture diameter : 4.54mmarrow_forward

- I want answers to all four questions if possible. Thanks for help :) Following experimental data are obtained from tensile test of a rectangular test specimen with original thickness of 2,5 mm, gauge width of 24 mm and gauge length of 101 mm: Load (N) Elongation (mm) 0 0 24372 0,183 23008 0,315 28357 5,777 35517 12,315 27555 17,978 23750 23,865 Based on the information above; draw stress-strain diagram of the material and answer the following questions. - Calculate the fracture strength (in MPa) of the material. - Calculate the percent elongation of the specimen at fracture point. - Determine the modulus of resilience (in N.mm/mm3) of the material. (Use at least five decimal units) - Determine the toughness index number (in N.mm/mm3) of the material.arrow_forwardIn a tensile test for an aluminum alloy, the sample is 2 inches long and 0.5 inches in diameter. The proportional portion of the tension stress-strain diagram for an aluminum alloy is shown below. It the diameter change of the sample was also monitored during the above test, and it was found that the lateral strain of the sample is 1/3 of its axial longitudinal strain, what is the Poisson' ratio of the material under test: ___. Calculate your answer to 2 decimal place.arrow_forwardIn tensile test a plain carbon steel specimen has a (40mm) gauge length and the Final area (A final) of specimen after tensile test was 264.327. The load which caused fracture was (122.5 KN). After fracture, the final length was 47.516mm The % reduction in area is * O 15.819% 18.819 O 17.819 O 20.819arrow_forward

- Question Following experimental data are obtained from tensile test of a rectangular test specimen with original thickness of 2,5 mm, gauge width of 24 mm and gauge length of 101 mm: Load (N) Elongation (mm) 0 0 24372 0,183 23008 0,315 28357 5,777 35517 12,315 27555 17,978 23750 23,865 Based on the information above; draw stress-strain diagram of the material and answer the following questions. - Calculate the yield strength (in MPa) of the material. - Calculate the percent elongation of the specimen at yield point. (Use at least five decimal units) - Calculate the stiffness (in MPa) of the specimen material. - Calculate the ultimate strength (in MPa) of the material. - Calculate the percent elongation of the specimen at point of ultimate strength.arrow_forwardBSEN10045 is British standard for Brinell Hardness test Select one: True Falsearrow_forwardwould you please describe this picture for me i have to present it to audience please to be more value?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY