Concept explainers

Shelby Shelving is a small company that

manufactures two types of shelves for grocery

stores. Model S is the standard model; model LX is

a heavy-duty version. Shelves are manufactured in

three major steps: stamping, forming, and assembly. In

the stamping stage, a large machine is used to stamp

(i.e., cut) standard sheets of metal into appropriate

sizes. In the forming stage, another machine bends the

metal into shape. Assembly involves joining the parts

with a combination of soldering and riveting. Shelby’s

stamping and forming machines work on both models

of shelves. Separate assembly departments are used

for the final stage of production.

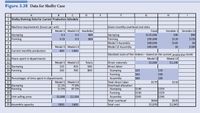

The file C03_01.xlsx contains relevant data

for Shelby. (See Figure 3.38.) The hours required on

each machine for each unit of product are shown

in the range B5:C6 of the Accounting Data sheet.

For example, the production of one model S shelf

requires 0.25 hour on the forming machine. Both

the stamping and forming machines can operate for

800 hours each month. The model S assembly department

has a monthly capacity of 1900 units. The

model LX assembly department has a monthly capacity

of only 1400 units. Currently Shelby is producing

and selling 400 units of model S and 1400 units of

model LX per month.

Model S shelves are sold for $1800, and model

LX shelves are sold for $2100. Shelby’s operation

is fairly small in the industry, and management at

Shelby believes it cannot raise prices beyond these

levels because of the competition. However, the

marketing department believes that Shelby can

sell as much as it can produce at these prices.

The costs of production are summarized in the

Accounting Data sheet. As usual, values in blue

cells are given, whereas other values are calculated

from these.

Management at Shelby just met to discuss next

month’s operating plan. Although the shelves are

selling well, the overall profitability of the company is

a concern. Doug Jameson, the plant’s engineer, suggested

that the current production of model S shelves

be cut back. According to Doug, “Model S shelves

are sold for $1800 per unit, but our costs are $1839.

Even though we’re selling only 400 units a month,

we’re losing money on each one. We should decrease

production of model S.” The controller, Sarah

Cranston, disagreed. She said that the problem was

the model S assembly department trying to absorb a

large overhead with a small production volume. “The

model S units are making a contribution to overhead.

Even though production doesn’t cover all of the fixed

costs, we’d be worse off with lower production.”

Your job is to develop an LP model of Shelby’s

problem, then run Solver, and finally make a recommendation

to Shelby management, with a short

verbal argument supporting Doug or Sarah.

USING SOLVER PLEASE SHOW FORMULAS

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 10 images

How does the requirement that the number of units of model LX produced be at least 60% of the total production affect profits?

What would the formula be for Cells B9 and C9 be to populate 0? Or is it just left blank?

How does the requirement that the number of units of model LX produced be at least 60% of the total production affect profits?

What would the formula be for Cells B9 and C9 be to populate 0? Or is it just left blank?

- Mack's guitar fabrication shop produces low cost, highly durable guitars for beginners. Typically, out of the 100 guitars that begin production each month, only 82 percent are considered good enough to sell. The other 18 percent are scrapped due to quality problems that are identified after they have completed the production process. Each guitar sells for $240. Because some of the production process is automated, each guitar only requires 10 labor hours. Each employee works an average of 160 hours per month. Labor is paid at $10 per hour, materials cost is $40 per guitar, and overhead is $3,800. Part 2 a. The labor productivity ratio for Mack's guitar fabrication shop isarrow_forwardThe term "process view of organizations" refers to the fact that a process includes manufacturing and services only. a process includes manufacturing only. a process includes any part of organization including accounts payables and receivables. a process includes services only. None of these answer choicesarrow_forwarda chain saw requires 4 hours of assembly and wood chipper 3 hours.A maximum of 36 hours of assembly time is available.The profit is $150 on a chain saw and 220 on a chipper.How many of each should be assembled for maximum profit?arrow_forward

- SM manufacturer produces scarves. They evenly split the $600 factory rent with GM gloves manufacturers, and the raw material for each scarf costs $2. If the selling price of a pair of GM gloves is $4 and a SM scarf is $5, how many scarves should SM sell to break even?arrow_forwardJack and Jill are starting a restaurant together. They want everyone at the restaurant to have a uniform look. Jack suggests they order black-and-pink outfits for everyone since the color scheme matches their branding. Jill suggests they simply ask everyone to wear black for work since everyone should own black pants and tops. Whose reasoning is more effectual? Jack's or Jill's typed answer correctly please. I ll ratearrow_forwardGMPs are a combination of manufacturing and management practices aimed at ensuring that food products are consistently produced to meet specifications and customer expectations. GMPs requirements related to the design and layout of food plants include: • Single-floor versus multistory buildings • Land space for future expansion• Waste disposal • Building details (drainage, doors, lighting,ventilation, plumbing) how can we apply GMPs into yogurt manufacturerarrow_forward

- Each column must have at least one value in some row to enable Pivot Tables to work properly. True Falsearrow_forwardMeritor, a company that makes muffler assemblies for the automotive industry, is committed to the use of kanban to pull material through its manufacturing cells. Meritor has designed each cell to fabricate a specific family of muffler products. Fabricating a muffler assembly involves cutting and bending pieces of pipe that are welded to a muffler and a catalytic converter. The mufflers and catalytic converters are pulled into the cell based on current demand. The catalytic converters are made in a specialized cell. Catalytic converters are made in batches of 10 units and are moved in special hand carts to the fabrication cells. The catalytic converter cell is designed so that different types of catalytic converters can be made with virtually no setup loss. Meritor hires a team of consultants. The consultants suggest a partial robotic automation as well as the safety stock to be 9 percent. Meritor implements these suggestions. The result is an increase in efficiency in both the…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.