Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

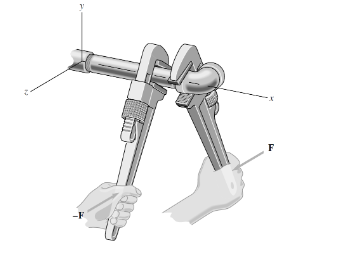

Two wrenches are used to tighten an elbow fitting. The force ?⃑ = [10 k] lbf on

the right wrench is applied at (6, -5, -3) inches, and the force −?⃑ on the left wrench is applied at

(4, -5, 3) inches.

a) Determine the moment about the x-axis due to the force exerted on the right wrench only.

b) Determine the moment of the couple formed by the forces exerted on both wrenches.

c) Based on the results of (a) and (b), explain why two wrenches are typically used for

tightening fittings.

the right wrench is applied at (6, -5, -3) inches, and the force −?⃑ on the left wrench is applied at

(4, -5, 3) inches.

a) Determine the moment about the x-axis due to the force exerted on the right wrench only.

b) Determine the moment of the couple formed by the forces exerted on both wrenches.

c) Based on the results of (a) and (b), explain why two wrenches are typically used for

tightening fittings.

Transcribed Image Text:-F

F

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 11 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Force F = 1,665 N acts from A towards B, as shown. Determine the magnitudes of the moments of force F about the following lines in N · m. (a) OC = (N · m) (b) OD = (N · m) (c) CD = (N · m) (d) BC = (N · m) (e) DE = (N · m) (f) DF = (N · m) (g) FG = (N · m)arrow_forwardA force F = 25 lb is applied to the handle of a socket wrench at point B, while a force N=15 lb is applied to the head of the socket wrench at point A to tighten a bolt at point O. (a) Compute the resultant force and moment at point O. (b) Determine a wrench resultant and the coordinates of the point at which the line of action of the wrench passes through the x-y plane. N 1.25, in. 7.5 in.arrow_forwardProblem 5 A force system is shown below. 75 kN 100° (4, 12) 160 KN 50 kN (0, 4) 20° 60° (10, 2) 80 KN-m O(0, 0) 200 kN 140° (13, -5) a. Determine the magnitude of the resultant? b. Determine the moment about the origin? c. Determine the distance of the resultant from the origin?arrow_forward

- While cutting a piece of paper, a person exerts the two indicated forces on a paper cutter. Reduce the two forces to an equivalent force-couple system at corner O and then specify the coordinates of the point P in the x- y plane through which the resultant of the two forces passes. The cutting surface is 30" x 30". 5 lb 24 Ib 15" 1" 5" Part 1 There are 2 distinct questions here. We will solve the first question now. Question 1: Replace the two forces shown by an equivalent force-couple system at point O. Find the force part of the force-couple system. Answer: F = i + j+ k) Ibarrow_forwardUniversity of East London Q.1 In the set up the determinant to find the moment of the force about point P? F= (-3i + 2j + Sk} kN -3 m 2 marrow_forwardQuestion 2 Find the moment of the force about each coordinate axis (x, y, and z). Then determine the moment of the force about line AO. Mx 72 Nm 2; My 3 108 Nm 6 ; Mzs 96 Nm 6 A (0,6.4)m - OR . Im B(8,0.6)m PART 1arrow_forward

- Ex ( 7): A ( 150 N ) force acts on the end of the ( 900 mm ) lever as shown in fig. Determine the moment of the force about ( 0). 150 N 900 mm 60•arrow_forwardPlease solve this question in handwriting step by step.arrow_forward4. Determine the magnitude of the moment of the force F = {50i20j - 80k} N about the a) base line AB of the tripod b) base line BC of the tripod c) base line AC of the tripod. 1.5 m 2m 2m 0.5 m D 1 m 2.5m 4 marrow_forward

- Determine the resultant moment produced by the force F about the shoulder S. The force F = 5 lb acts at point P, at an angle 0 = 9 deg. Provide your answer in units of lb-in, accurate to at least one decimal point. Be sure to enter the correct sign! S 30° -12 in.- E 13 in. 40° P Ө Farrow_forwardPlease show me the stepsarrow_forwardQ.4) A pipe assembly is acted on by four forces and one couple moment. The 300 N force is parallel with the z-axis, the 130N force is parallel with the y-axis, and the 60 N force is parallel with the x-axis. Force F, has a magnitude of 220 N and coordinate direction angles given by aA 45°, BA = 60°, and YA = of 400 N•m. Determine the resultant moment about point B. 120°. The couple moment M. is in the x-z plane and has a magnitude %3D %3D Mc 30° 300 N 1 m 0.75 m В 0.5 m E 00 N 0.75 m A 130 N FAarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY