Understanding Business

12th Edition

ISBN: 9781259929434

Author: William Nickels

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

Explain the impact of streamlined distribution in different networks. (Please refer to the given lesson)

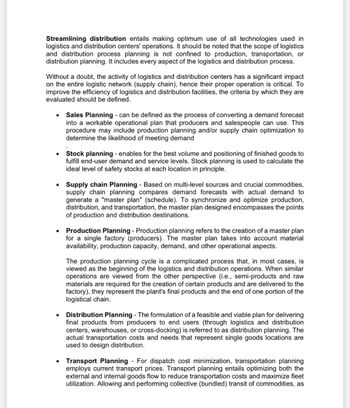

Transcribed Image Text:Streamlining distribution entails making optimum use of all technologies used in

logistics and distribution centers' operations. It should be noted that the scope of logistics

and distribution process planning is not confined to production, transportation, or

distribution planning. It includes every aspect of the logistics and distribution process.

Without a doubt, the activity of logistics and distribution centers has a significant impact

on the entire logistic network (supply chain), hence their proper operation is critical. To

improve the efficiency of logistics and distribution facilities, the criteria by which they are

evaluated should be defined.

●

Sales Planning - can be defined as the process of converting a demand forecast

into a workable operational plan that producers and salespeople can use. This

procedure may include production planning and/or supply chain optimization to

determine the likelihood of meeting demand

Stock planning - enables for the best volume and positioning of finished goods to

fulfill end-user demand and service levels. Stock planning is used to calculate the

ideal level of safety stocks at each location in principle.

• Supply chain Planning - Based on multi-level sources and crucial commodities,

supply chain planning compares demand forecasts with actual demand to

generate a "master plan" (schedule). To synchronize and optimize production,

distribution, and transportation, the master plan designed encompasses the points

of production and distribution destinations.

Production Planning - Production planning refers to the creation of a master plan

for a single factory (producers). The master plan takes into account material

availability, production capacity, demand, and other operational aspects.

The production planning cycle is a complicated process that, in most cases, is

viewed as the beginning of the logistics and distribution operations. When similar

operations are viewed from the other perspective (i.e., semi-products and raw

materials are required for the creation of certain products and are delivered to the

factory), they represent the plant's final products and the end of one portion of the

logistical chain.

Distribution Planning - The formulation of a feasible and viable plan for delivering

final products from producers to end users (through logistics and distribution

centers, warehouses, or cross-docking) is referred to as distribution planning. The

actual transportation costs and needs that represent single goods locations are

used to design distribution.

Transport Planning - For dispatch cost minimization, transportation planning

employs current transport prices. Transport planning entails optimizing both the

external and internal goods flow to reduce transportation costs and maximize fleet

utilization. Allowing and performing collective (bundled) transit of commodities, as

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- analyze how digital channels and traditional channels can complement each other in a comprehensive marketing strategy, analyzing integrated marketing campaigns that effectively combine both digital and traditional elements.arrow_forwardExamine the development of e-commerce, digital marketing platforms and channels in comparison to physical channels.arrow_forwardfuture technology related to distribution businessarrow_forward

- One disadvantage of direct-to-customer channels is that Multiple Choice most organizational buyers are used to relying on intermediaries to serve as their purchasing advisors. they require producers to shift many marketing functions to others. this approach makes it hard to achieve coordination among the required marketing activities. they make it more difficult to get information about changing needs of the market. None of the answers are correct.arrow_forwardWhat are some of Vivobarefoot's competitive advantages as a result of its infrastructure upgrade?arrow_forwardHow are nontraditional channels of distribution affecting your organization and its marketing strategy? Appraise the situation and discuss.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON

Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning

Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON

Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON

Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Understanding Business

Management

ISBN:9781259929434

Author:William Nickels

Publisher:McGraw-Hill Education

Management (14th Edition)

Management

ISBN:9780134527604

Author:Stephen P. Robbins, Mary A. Coulter

Publisher:PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract...

Management

ISBN:9781305947412

Author:Cliff Ragsdale

Publisher:Cengage Learning

Management Information Systems: Managing The Digi...

Management

ISBN:9780135191798

Author:Kenneth C. Laudon, Jane P. Laudon

Publisher:PEARSON

Business Essentials (12th Edition) (What's New in...

Management

ISBN:9780134728391

Author:Ronald J. Ebert, Ricky W. Griffin

Publisher:PEARSON

Fundamentals of Management (10th Edition)

Management

ISBN:9780134237473

Author:Stephen P. Robbins, Mary A. Coulter, David A. De Cenzo

Publisher:PEARSON