Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

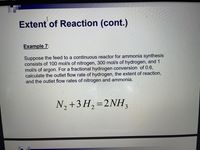

Transcribed Image Text:Extent of Reaction (cont.)

Example 7:

Suppose the feed to a continuous reactor for ammonia synthesis

consists of 100 mol/s of nitrogen, 300 mol/s of hydrogen, and 1

mol/s of argon. For a fractional hydrogen conversion of 0.6,

calculate the outlet flow rate of hydrogen, the extent of reaction,

and the outlet flow rates of nitrogen and ammonia.

N, +3 H,=2NH,

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please solve this questionarrow_forwardIn Figure P11.6 you will see two successive liquid separations columns operating in tandem in the steady state (and with no reaction taking place). The compositions of the feed and products are as shown in the figure. The amount of W₂ is 20% of the feed. Focus only on the material balances. Write down the names of the material bal- ances for each column treated as separate units (one set for each column), along with the balances themselves placed next to the names of the balances. Also, place an as- terisk in front of the names of the balances that will comprise a set of independent equations for each column. Write down in symbols the unknowns for each column. Calculate the degrees of freedom for each column separately. AD W₁ % Feed 100 kg A 15 % A 60 B 20 B 30 C 55 C 20 ▲ P₁ P₂ W₂ % A 10 B 85 C5 % A 0.2 в 7 C ?arrow_forwardGive two reasons (short statements) why the rate of a catalyzed reaction mightdecrease as the pressure of one of its products increases.arrow_forward

- Prepare a material flowsheet similar to Figure 6.1 (shown below) for production of 2400 lb-mol/hr of Vinyl Chloride (VC) based on the reaction path #5 with the operating parameters provided below. You MUST show the Molar flow rates of ALL compounds in ALL streams in your flowsheet. Reaction Path #5. Balanced process for Chlorination of Ethylene C2H4 + Cl2--> C2H4CI2 (C) Ileat Liberated Ileat Absorbed y Reactinn 150 x 10 Blutr duriag Reaction = 52 x 10 Bluhr C2H4 + 2HCI + 1/2 O2--> C2H4CI2 + H2O 2C2H4CI2 --> 2C;H3CI + 2HCI (E) (D) 58.300 Ibhr 2C2H4 + Cl2 +1/2 O2 --> 2C2H3CI + H2O (C) 100% Conv. of Cl2 at 80°C and 150 kPa with 15% (G) Direct Chlorination YƯ C, 15 atm Pyrolysis Sorc +CH,CI- 26 ata HCI CH.CI, CAL 11.3,4KI hr 158,I Ihyhr CH,CI, C1,CI 4,900 Ihhr CH, -a CH,CI, excess C2H4 CH,ClCH,CI + HCI (E) 100% Conv. of HCl at 275°C and 150 kPa with 5% 105,500 Ib'hr excess C2Н4 (D) 75% Conv. At 500 °C and 3000 kPa. Water is separated from the mixture before entering Figure 6.1 reactor D.arrow_forwardQ2- The synthesis of ammonia proceeds according to the following reaction N₂ + 3 H₂ -----> 2 NH3 In a given plant, 4202 lb of nitrogen and 1046 lb of hydrogen are fed to the synthesis reactor per hour. Production of pure ammonia from this reactor is 3060 lb per hour. a. What is the limiting reactant. b. What is the percent excess reactant. c. What is the percent conversion obtained (based on the limiting reactant).arrow_forward4-23. A mixture of ethanol (A) and water (B) is separated in a distillation column. The volumetric flow rate of the feed stream is 5 m'/hr. The concentration of ethanol in the feed is c,=2,800 mol/m'. The distillate leaves the column with a concentration of ethanol c, =13,000 mol/m. The volumetric flow rate of 3 distillate is one cubic meter per hour. How much ethanol is lost through the bottoms of the column, in kilograms of ethanol per hour?arrow_forward

- A reactor is used for oxidation of a chemical compound. The reaction rate constant k is 0.8 h HRT is 4 h. The oxidation efficiency is 96%. Determine the flow regime in the reactor.arrow_forwardA) Construct a complete stoichiometric table for the molar flow rate and gas-phase concentrations using the correct limiting reactantarrow_forwardA binary distillation is performed so that a distillate 94% and bottoms 8% in of the more volatile Component A results. The process shown below reflects one operating condition of a feed stream. Rectification, Stripping and the q-line are all provided on the x-y diagram below. Aling with expected stage for the distillation.. What is temperature of the liquid stream leaving the reboiler? What is the temperature of the vapor stream leaving the feed stage? What is the temperature of the liquid stream leaving stage 2? What is the temperature of the liquid reflux returned to the column? Note: A total condensor is installed.arrow_forward

- The following reaction takes place in a catalytic reactor: NO2+O2 → NO3 In the process 1000 mol/s of NO3 are produced. The reaction has 90% conversion and air with 20% excess is supplied. Calculate the flow rates of the system.arrow_forward-2 The hydrolysis of urea by urease occurs in a batch bioreactor. The reaction follows a Michaelis- Menten mechanism. The following kinetic data are available for urea: K'm=7.7×10 M, v =0.5 mole/L/min. The initial concentration of urea in the reactor is 50 mole/L. m E+S ES-²E + P Vm[S] Km + [S] Calculate the concentration of urea in the reactor 10 minutes after the reaction starts v= (Hint: it is a batch reactor, meaning that you need to integrate the MM, see module 1 for details of batch reactors).arrow_forwardIn a batch reactor, a substance A was processed, which generated different products (D and U), through competitive parallel reactions with the following reaction kinetics: After 20 minutes of reaction, it was determined that the composition of the reaction medium was CA = 1 mol/L, CD = 5 mol/L, CU = 2 mol/L. The option that indicates, respectively, the instantaneous and global selectivities at the end of the reaction are: A) 3 and 2. B) 2.5 and 2. C) 2 and 3. D) 2 and 2.5.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The