Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

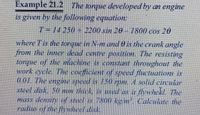

Transcribed Image Text:Example 21.2 The torque developed by an engine

is given by the following equation:

T=14 250 +2200 sin 20-1800 cos 20

where Tis the torque in N-m and 0 is the crank angle

from the inner dead centre position. The resisting

torque of the machine is constant throughout the

work cycle. 1The coefficient of speed fluctuations is

0.01. The engine speed is 150 rpm. A solid circular

steel disk, 50 mm thick, is used as a flywhekl. The

mass density of steel is 7800 kg m. Calculate the

radius of the flywheel disk.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- b) Fig. 3 shows a graph that has variable drive torque and constant load torque. The load (2 torque is 500Nm with average speed of 30rpm. A complete cycle for the system is 3x radian. Determine thickness of the flywheel if you want to reduce the coefficient speed of fluctiation from 0.15 to 0.1. Assume the diameter for the flywheel is 50cm and material used is steel (p = 8050kg/m³) le.. Torque (N-m) cm 750 220 K 2n 3 8h3 3" 3n 8(rad)arrow_forwardSTEAM ENGINE PROBLEM. Please solve carefully/ellaborately and include the untis in every step, show diagram and write your solutions clearly and must be readable if your solution is in written form. Your work will be appreaciated much. Thank You.arrow_forwardFind the piston size of a 4-stroke, 4-cylinder engine, given the following Crankshaft rotation = 2500 rpm Mean Effective Pressure = 162 psi Indicated horsepower = 125 Bore-stroke ration = 1:1.5arrow_forward

- 8)A 35 kW motor running at 1200 r.p.m. drives a compressor at 780 r.p.m through a 90° bevel gearing arrangement. The pinion has 30 teeth. The pressure angle of teeth is 14 1/2°. The wheels are capable of withstanding a dynamic stress, 280 140 MPa, 280 +v where v is the pitch line speed in m /min. The form factor for teeth may be taken as: 0.686 0.124 - TE where TE is the number of teeth equivalent of a spur gear. The face width may be taken as % of the slant height of pitch cone. Determine for the pinion, the module pitch, face width, addendum, dedendum, outside diameter and slant height.arrow_forwardCalculate the indicated power of a cylinder and the engine, if the mechanical efficiency of the engine is given as 75 % Calculate the brake power and friction power of the engine. Provide your answer in kW and hp. Study the power if the engine is a four stroke type. Cylinder bore 500 Piston stroke 2,050 Stroke/bore ratio Speed range Mean effective pressure = 2050/500 124-99 19.5 Maximum cylinder pressure Numbers of cylinders 5 to 8 Feedback: Correct answer = 155 mm mm rev/min bar bararrow_forwardThe following data were taken during a one-hour trial run on a single cylinder, single acting, four-stroke diesel engine of cylinder diameter of 175 mm and stroke 225 mm , the speed being constant at 1000 rpm : Indicated mep: 5.5 barsDiam. of rope brake: 1066 mmLoad on brake: 400 NReading of balance: 27 NFuel consumed: 5.7 kgCalorific value: 44.2 MJ/kg Calculate the indicated power, brake power, specific fuel consumption per indicated kWh and per brake kWh , mechanical efficiency, indicated thermal and brake thermal efficiency.arrow_forward

- An engine having five cylinders in line, as shown in Figure Q5, has successive cranks 1440 apart, the distance between cylinder centre lines being 450 mm. The reciprocating mass for each cylinder is 12 kg, the crank radius is 120 mm and the connecting rod length is 450 mm. The engine runs at 650 rev/min.arrow_forward14. A single cylinder internal combustion engine working on the four stroke cycle develops 75 kW at 360 r.p.m. The fluctuation of energy can be assumed to be 0.9 times the energy developed per cycle. If the fluctuation of speed is not to exceed 1 per cent and the maximum centrifugal stress in the flywheel is to be 5.5 MPa, estimate the mean diameter and the cross-sectional area of the rim. The material of the rim has a density of 7.2 Mg/m³. [Ans. 1.47 m; 0.088 m²]arrow_forwardsolve both, show all steps and solutions... answers providedarrow_forward

- HW8 A shaft fitted with a flywheel rotates at 650 r.p.m. and drives a machine. The torque of machine varies in a cyclic manner over a period of 2 revolutions. The torque rises from 650 N-m to 2200 N-m uniformly during 110° and remains constant for the following 270°. It then falls uniformly to 600 N-m during the next 100° and remains constant for the end cycle, the cycle being repeated thereafter. Determine the power required to drive the machine and percentage fluctuation in speed, if the driving torque applied to the shaft is constant and the mass of the flywheel is 180 kg with radius of gyration of 35 cm. HW9arrow_forward5. A 5.6 liter V10 compression-ignition truck engine operates on a four stroke cycle at 3600 rpm producing 162 kW of power in the shaft. The bore and stroke of the engine are related as S = 1.12 B. Calculate: (15 pts) a. Average piston speed (m/s) b. Torque (N-m) c. Brake mean effective pressurearrow_forwardYou are asked to design a four cylinder four-stroke spark ignition engine for a passenger car, which is required to provide a maximum brake torque of (2.60x10^2) Nm at the rated speed of (7.000x10^3) rpm. To simply the design, the bore (B)/stroke (L) ratio is assumed to be unit, i.e. B=L. Given that the bmep of the engine is assumed to be (7.000x10^2) KPa, find its mean piston speed. The answer should be in the unit of m/s with 3 significant figures. Note: Your answer is assumed to be reduced to the highest power possible. Your Answer: Question 7 options: x10 Answerarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY