Understanding Business

12th Edition

ISBN: 9781259929434

Author: William Nickels

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

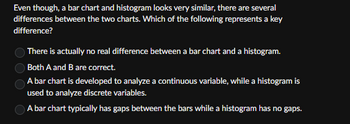

Transcribed Image Text:Even though, a bar chart and histogram looks very similar, there are several

differences between the two charts. Which of the following represents a key

difference?

000 0

There is actually no real difference between a bar chart and a histogram.

Both A and B are correct.

A bar chart is developed to analyze a continuous variable, while a histogram is

used to analyze discrete variables.

A bar chart typically has gaps between the bars while a histogram has no gaps.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- 3/4 roller chain is to transmit power from a 17-tooth drive sprocket to 34-tooth sprocket. Centers of the sprockets are 13 inches apart. Estimate the number of teeth in contact with the chain for the larger sprocket.arrow_forwardC-Spec, Incorporated is attempting to determine whether an existing machine is capable of milling an engine part that has a key specification of 4 ± 0.003 inch. After a trial run on this machine, C-Spec has determined that the machine has a sample mean of 4.001 inches with a standard deviation of 0.002 inch. Calculate the capability index ( Cpk��� ) for this machine. Note: Round your answer to 3 decimal places. Should C-Spec use this machine to produce this part? multiple choice Yes Noarrow_forward26. Discuss the following pro and con positions on using optimization models to design control charts: Con: “These models are useless to me because I don’t feel I can accurately estimate the values of the required inputs." Pro: “The choice of specific values of n and k in the construction of X bar charts means that you are assuming values for the various system costs and parameters. You might as well take the bull by the horns and obtain the best estimates you can and use those to design the X bar chart."arrow_forward

- Auto pistons at Wemming Chung's plant in Shanghai are produced in a forging process, and the diameter is a critical factor that must be controlled. From sample sizes of 5 pistons produced each day, the mean and the range of this diameter have been as follows: Day Mean (mm) Range R (mm) 158 4.3 151.2 4.4 155.7 4.2 153.5 4.8 156.6 4.5 What is the UCL using 3-sigma?(round your response to two decimal places). 1. 2. 4.arrow_forwardSuppose you are analyzing processing times for a machining operation. In your analysis, you found C, = 2.1 and Cpk = 1.28. Given this information, which of the following sigma levels is the highest that you could claim your process is capable of meeting? O 1 sigma O 2 sigma 3 sigma O 4 sigma 5 sigma O 6 sigmaarrow_forward(c) Based on what we know about Observation B, if the cutoff value is lowered to 0.2, what happens to the values of sensitivity and specificity? Explain. Use the ROC curve to estimate the values of sensitivity and specificity for a cutoff value of 0.2. If required, round your answers to three decimal places. Do not round intermediate calculations. Answer Part C, there are no other parts here. I have the sensitivity already and is equal to 1. What is the specificity??If you are not 100% sure you are right, do not attempt this is frustrating. The cutoff value has changed from 0.5 to 0.2. The sensitivity is 1 which is correct. I need help with the specificity. Sensitivity does not equal 1/14 and specificity does not equal 1/31 so don't answer that and do not answer any other parts just answer part C.arrow_forward

- Twelve samples, each containing five parts, were taken from a process that produces steel rods at Emmanual Kodzi's factory. The length of each rod in the samples was determined. The results were tabulated and sample means and ranges were computed. The results were: Sample Sample Mean (in.) Range (in.) Sample Sample Mean (in.) Range (in.) 1 9.602 0.033 7 9.603 0.041 2 9.602 0.041 8 9.605 0.034 3 9.593 0.034 9 9.597 0.027 4 9.606 0.051 10 9.601 0.029 5 9.599 0.031 11 9.603 0.039 6 9.599 0.036 12 9.606 0.047 Part 2 For the given data, the x double overbarx = 9.6013 inches (round your response to four decimal places). Part 3 Based on the sampling done, the control limits for 3-sigma x overbarx chart are: Upper Control Limit (UCL Subscript x…arrow_forwardA machine cuts circular filters from large rolls of material. The diameters of the filters are normally distributed with a mean of 2.00 cm and a standard deviation of 0.02 cm. Specifications call for the filters to have diameters between 1.95 cm and 2.03 cm. What percent of production does not meet specificationsarrow_forward28. A local contractor manufactures the speakers used in telephones. The phone com- pany requires the speakers to ring at a specified noise level (in decibels). An X chart is being designed to monitor this variable. The process of sampling speakers from the line requires hitting the speakers with a fixed-force clapper and measur- ing the decibel level on a meter designed for that purpose. The cost of sampling is $1.25 per speaker. When the process goes out of control, the thickness of the speakers is incorrect. The cost of searching for an assignable cause is estimated to be $50. The cost of operating the process in an out-of-control state is estimated to be $180 per hour. Out of control corresponds to a shift of 2ơ in the decibel level, and the probability that the process shifts out of control in any hour is .03. a. The company uses an X chart based on 3ơ limits and subgroups of size 4. What is its hourly cost? b. What are the optimal values of n and k for this process and the…arrow_forward

- A process sampled 20 times with a sample of size 8 resulted in = 28.5 and R = 1.8. Compute the upper and lower control limits for the chart for this process. (Round your answers to two decimal places.) UCL = LCL = Compute the upper and lower control limits for the R chart for this process. (Round your answers to two decimal places.) UCL = LCL =arrow_forwardS Book Hint Print eferences Problem 13-2 (Algo) A metal fabricator produces connecting rods with an outer diameter that has a 1 ± 0.02 inch specification. A machine operator takes several sample measurements over time and determines the sample mean outer diameter to be 1.004 inches with a standard deviation of 0.006 inch. Calculate the process capability index for this example. (Round your answer to 3 decimal places.) Process capability indexarrow_forwardThe relative size of errors is shown by: Residuals MSE O Bias MAD MAPEarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON

Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning

Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON

Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON

Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Understanding Business

Management

ISBN:9781259929434

Author:William Nickels

Publisher:McGraw-Hill Education

Management (14th Edition)

Management

ISBN:9780134527604

Author:Stephen P. Robbins, Mary A. Coulter

Publisher:PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract...

Management

ISBN:9781305947412

Author:Cliff Ragsdale

Publisher:Cengage Learning

Management Information Systems: Managing The Digi...

Management

ISBN:9780135191798

Author:Kenneth C. Laudon, Jane P. Laudon

Publisher:PEARSON

Business Essentials (12th Edition) (What's New in...

Management

ISBN:9780134728391

Author:Ronald J. Ebert, Ricky W. Griffin

Publisher:PEARSON

Fundamentals of Management (10th Edition)

Management

ISBN:9780134237473

Author:Stephen P. Robbins, Mary A. Coulter, David A. De Cenzo

Publisher:PEARSON