Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Draw a stress-strain curve for a low carbon steel and explain important points and regions in detail. What fracture behavior does this steel exhibit?

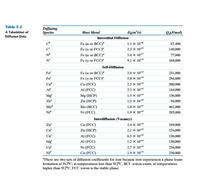

Transcribed Image Text:Table 5.2

A Tabulation of

Diffusing

Species

D(m²/s)

Host Metal

QJ/mol)

Diffusion Data

Interstitial Diffusion

Fe (a or BCC)

1.1 x 10-

87,400

Fe (y or FCC)

2.3 x 10-

148,000

Fe (a or BCC)

5.0 x 10-7

77,000

N°

Fe (y or FCC)

9.1 x 10-

168,000

Self-Diffusion

Fe

Fe (a or BCC)“

Fe (y or FCCY

2.8 x 10-

251,000

Fe

5.0 x 10-

284,000

Cu (FCC)

Al (FCC)

Cu

2.5 x 10-

200,000

Al

2.3 x 10-

144,000

Mg

Mg (HCP)

1.5 x 10

136,000

Zn

Zn (HCP)

1.5 x 10-

94,000

Mo

Mo (BCC)

1.8 x 10-

461,000

Ni

Ni (FCC)

1.9 x 10

285,000

Interdiffusion (Vacancy)

Cu (FCC)

Zn (HCP)

Zn

2.4 x 10-

189,000

Cu

2.1 x 10-

124,000

Cuf

Al (FCC)

6.5 x 10-

136,000

Mg

Al (FCC)

1.2 x 10-

130,000

Cuf

Ni (FCC)

2.7 x 10-

256,000

Ni

Cu (FCC)

1.9 x 10-

230,000

*There are two sets of diffusion coefficients for iron because iron experiences a phase trans-

formation at 912°C; at temperatures less than 912°C, BCC a-iron exists; at temperatures

higher than 912°C, FCC y-iron is the stable phase.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Specify a copper alloy that requires at least 50% elongation and at least 300 MPa tensile strength.arrow_forwardA component made of 7075-T6 aluminum alloy has an edge crack of 1.4 mm in length. Plane strain fracture toughness of this alloy is given as 27 MPavm. Geometrical factor of the crack is given as 1.2. (a) If this alloy is subjected to uniaxial tensile stress of 380 MPa, determine whether sudden brittle fracture occurs or not. (b) Calculate the maximum allowable crack size for this component in order not to be failed in brittle manner under a stress of 1000 MPa (Density of steel 7.85 g/cm³, 9.80665 N = 1 kg). Modulus of elastisity, GPa Ultimate tensile Yield strength, Alloy strength, MPa MPa 2014 Al alloy Bronze (92Cu-8Sn) High carbon steel Pure Titanium 97 186 380 72 110 152 380 615 215 240 330 107arrow_forward(a) A large medium carbon steel crane hook is thought to contain penny- shaped internal cracks. If the non-destructive test equipment used on the hook is not capable of detecting cracks smaller than 20 mm diameter, determine the fracture toughness required from this steel if the safety factor on stress is to be 2. The yield stress of the AISI 1045 grade steel is 1050 MNm². Note: For this crack geometry, the 'compliance function' Y in the Stress Intensity Factor (K)) may be taken as 1. (b) A surface crack of 2.5 mm depth and a certain length is found in a thick rectangularcomponent. The component is schedule to be repaired in 6 months. The component is subjected to zero to maximum stress of 340 MPa, 50 times per hour. It was known that for this component catastrophic failure occurs when the crack size reaches 12 mm in depth. Assuming that the crack geometrical shape (aspect ratio) remains constant during crack growth, will the component fail before repair? For the crack geometry, the…arrow_forward

- Suppose that a wing component on an aircraft is fabri- cated from an aluminum alloy that has a plane-strain fracture toughness of 26.0 MPa Vm (23.7 ksi Vin.). It has been determined that fracture results at a stress of 112 MPa (16,240 psi) when the maximum internal crack length is 8.6 mm (0.34 in.). For this same component and alloy, compute the stress level at which fracture will occur for a critical internal crack length of 6.0 mm (0.24 in.).arrow_forwardDetermine the tensile strength, yield strength and percentage elongation (% ductility) for an iron- carbon alloy with 0.76 wt % carbon composition. O Yield strength - 60000 psi : Tensile strength - 110000 psi: Ductility - 15% O Yield strength - 130000 psi : Tensile strength - 68000 psi;: Ductility - 10% O Yield strength - 68000 psi : Tensile strength - 130000 psi; Ductility - 10% O Yield strength 50000 psi: Tensile strength - 100000 psi: Ductility - 20% O Yield strength - 86000 psi : Tensile strength 150000 psi: Ductility 25%arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY