Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

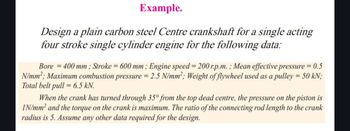

Transcribed Image Text:Example.

Design a plain carbon steel Centre crankshaft for a single acting

four stroke single cylinder engine for the following data:

Bore=400 mm; Stroke = 600 mm; Engine speed = 200 r.p.m.; Mean effective pressure = 0.5

N/mm²; Maximum combustion pressure = 2.5 N/mm²; Weight of flywheel used as a pulley = 50 kN;

Total belt pull = 6.5 kN.

When the crank has turned through 35° from the top dead centre, the pressure on the piston is

IN/mm² and the torque on the crank is maximum. The ratio of the connecting rod length to the crank

radius is 5. Assume any other data required for the design.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step 1: Write the given data.

VIEW Step 2: Calculate the pressure force on combustion.

VIEW Step 3: Calculate the horizontal and vertical reactions.

VIEW Step 4: Design the crank-pin.

VIEW Step 5: Design of shaft under the flywheel.

VIEW Step 6: Design of crankshaft When crank is at angle of maximum twisting moment.

VIEW Step 7: Design of crankpin-

VIEW Step 8: Design shaft under the flywheel-

VIEW Step 9: Calculate the direct compressive stress and twisting moment on arm.

VIEW Solution

VIEW Step by stepSolved in 10 steps with 73 images

Knowledge Booster

Similar questions

- Design a plain carbon steel Centre crankshaft for a single acting four stroke single cylinder engine for the following data: Bore = 400 mm ; Stroke = 600 mm ; Engine speed = 200 r.p.m. ; Mean effective pressure = 0.5 N/mm²; Maximum combustion pressure = 2.5 N/mm²; Weight of flywheel used as a pulley = 50 kN; Total belt pull = 6.5 kN. When the crank has turned through 35° from the top dead centre, the pressure on the piston is IN/mm² and the torque on the crank is maximum. The ratio of the connecting rod length to the crank radius is 5. Assume any other data required for the design.arrow_forwardFind the piston size of a 4-stroke, 4-cylinder engine, given the following Crankshaft rotation = 2500 rpm Mean Effective Pressure = 162 psi Indicated horsepower = 125 Bore-stroke ration = 1:1.5arrow_forward1. A four stroke internal combustion engine has the following specifications: Brake power = 7.5 kW; Speed 1000 r.p.m.; Indicated mean effective pressure = 0.35 N/mm2;Maximum gas pressure = 3.5 N/mm2; Mechanical efficiency = 80 %. Determine: 1. The dimesions of the cylinder, if the length of stroke is 1.4 times the bore of the cylin- der; 2. Wall thickness of the cylinder, if the hoop stress is 35 MPa; 3. Thickness of the cylinder head and the size of studs when the permissible stresses for the cylinder head and stud materials are 45 MPa and 65 MPa respectively.arrow_forward

- Seatwork No. 1 An SI I-2 square engine operates on a 2-stroke cycle at 2400 rpm. The average piston speed is 15 m/se and the no. of piston action is 2. When the piston is at its maximum position the remainder volume is 0.005 Liters. Determine: a. Volumetric displacement per unit time for all cylinders (m³/sec) b. Compression ratio c. Volume at Bottom Dead Center (m³)arrow_forwardcampute the bending stress number for the goer pair described by the given data beLow. KS= 1, Km= 1,21, F= 2.00 in, DP= 3,33 in, NG= 70, Np=20 hp = 1750v. p.m, Av=11, Pd =6, Tp= 900ib V1= 1527 ft/min The matarial used for pinion a gear is cast ironarrow_forwardA certain six cylinder engine has a 130.2 mm bore, a 127 mm stroke, and a clearance volume of 0.119 L in each cylinder;a.) Calculate the displacement in each cylinderb.) Calculate the compression ratio of the enginec.) Is the engine a diesel or an Otto cycle engine?arrow_forward

- 1. A 4-stroke, single-cylinder gasoline engine has 85-mm bore and 85-mm stroke. What is the piston displacement of the engine? If the engine has a 10-compression ratio, what is its clearance volume? What would be the total volume of the cylinder? 2. A four-stroke gasoline engine is running at a speed of 3,000 rpm. The piston diameter is 4 inches while the stroke is 4.5 inches. What is the speed of the piston? 3. A four-cylinder gas engine has 20-cm cylinder diameter and 40-cm stroke. The cylinders run at 150 rpm speed. The engine is a four-stroke cycle with 8 kg/cm² mean effective pressure. What is the area in cm2 and length of stroke of the engine piston in meter? Also, compute the power stroke per min per cylinder and the total power stroke of the 4 cylinders. Compute the indicated horsepower and the brake horsepower of the engine. And, what is the stroke-to-bore ratio of the engine? 4. Compute the specific fuel consumption of the 10 hp engine that drive a power tiller if it…arrow_forwardQ3/ A single cylinder four stroke cycle I.C. engine when tested, the following observations available: Area of indicator diagram = 3 sq.cm, Length of indicator diagram 4 cm, Spring constant = 10 bar/cm, Speed of engine = 400 rpm, Brake drum diameter = 120 cm, Dead weight on brake = 380 N, Spring balance reading 50 N, Fuel consumption = 2.8 kg/hr., Cv = 42000 kJ/kg, Cylinder diameter= 16 cm, Piston stroke = 20 cm. Find : (i) F.P, (ii) Mechanical efficiency, (iii) bsfc, and (iv) Brake thermal efficiency. %3D %3D %3Darrow_forwardA diesel engine four-stroke cycle with three cylinder has a cylinder bore of 90 mm and a stroke of 120 mm. The compression ratio is 16:1 and running at a speed of 2000 rpm. What is the clearance volume of the engine per cylinder?arrow_forward

- 6. The turning moment diagram for a four stroke gas engine may be assumed for simplicity to be repre- sented by four triangles, the areas of which from the line of zero pressure are as follows: Expansion stroke = 3550 mm²; exhaust stroke = 500 mm²; suction stroke = 350 mm²; and compres- sion stroke 1400 mm². Each mm² represents 3 N-m. Assuming the resisting moment to be uniform, find the mass of the rim of a flywheel required to keep the mean speed 200 r.p.m. within ± 2%. The mean radius of the rim may be taken as 0.75 m. Also determine the crank positions for the maximum and minimum speeds. [Ans. 983 kg; 4° and 176° from I. D. C]arrow_forwardin a four-stroke engine what is the ratio of cam to crank shaft revolutions ? What are some benefits of a hemispherical head shape?arrow_forwardi need the answer quicklyarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY