Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

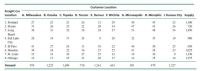

The National Western Railroad’s rail network covers most of the U.S. West and Midwest. On a

daily basis it sends empty freight cars from various locations in its rail network to its customers

for their use. Sometimes there are not enough freight cars to meet customer demand. The transportation

costs for shipping empty freight cars, shown as follows, are directly related to distance

traveled and the number of rail centers that must handle the car movement. Determine the number of empty freight cars that should be sent from each rail network location

to customers to meet demand at the minimum total cost.

Transcribed Image Text:Customer Location

Freight Car

Location

A. Milwaukee B. Omaha C. Topeka D. Tucson E. Denver F. Wichita G. Minneapolis H. Memphis L. Kansas City Supply

1. Portland

27

23

23

26

21

29

40

45

23

1,100

2. Fresno

31

26

25

22

20

34

47

43

26

720

3. Long

38

31

32

18

24

27

51

48

34

1,450

Beach

4. Salt Lake

28

18

17

24

9.

20

32

35

19

980

City

5. El Paso

41

27

24

11

18

22

46

30

25

650

6. Houston

38

24

22

16

27

25

41

28

23

1,025

7. St. Louis

8. Chicago

15

14

10

27

23

12

19

10

9.

1,330

12

13

15

31

26

17

14

15

14

1,275

Demand

974

1,225

1,690

710

1,261

663

301

479

1,227

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- The two most frequently cited reasons for starting a private trucking company are service and expense. Discuss the benefits of private trucking in terms of operation and expense.arrow_forwardIn this problem, your company is a distributor of products. You serve as an inventorymanager for the regional distribution center (DC) here in the Atlanta area. In this role,you schedule the purchase and shipment of products from various suppliers inbound to theAtlanta DC. Once you receive the products at the DC, they are stored in inventory untilthey are picked, packed, and shipped outbound to your company’s downstream customersin response to orders.For each of your products, you currently use a single, dedicated supplier. Each of yoursuppliers ships their products to you from their facility using trucking services, and theyprovide you with choices of different LTL or truckload trucking carriers depending on yourshipment size.Consider managing inventory now for product 101 produced by Supplier A. Currently,you face demand for product 101 of about 200 units per week. Each unit of product 101has a purchase cost p of $500 and you decide to value your inventory at the slightly higherrate…arrow_forwardThe following network describes a transportation scenario in which there are four sources A, B, C, and D, and three destinations P, Q, and R. (The numbers next to each arrow represent the cost of transporting one unit from that particular source to the destination located at the other end of that arrow). Write the mathematical formulation of the problem. Use the Excel Solver to solve the problem. Generate the answer and sensitivity reports in Excel, and submit your Excel workbook as a separate attachment. Provide the solution obtained in the space provided. What is the optimal cost of transportation?arrow_forward

- In this problem, your company is a distributor of products. You serve as an inventorymanager for the regional distribution center (DC) here in the Atlanta area. In this role,you schedule the purchase and shipment of products from various suppliers inbound to theAtlanta DC. Once you receive the products at the DC, they are stored in inventory untilthey are picked, packed, and shipped outbound to your company’s downstream customersin response to orders.For each of your products, you currently use a single, dedicated supplier. Each of yoursuppliers ships their products to you from their facility using trucking services, and theyprovide you with choices of different LTL or truckload trucking carriers depending on yourshipment size.Consider managing inventory now for product 101 produced by Supplier A. Currently,you face demand for product 101 of about 200 units per week. Each unit of product 101has a purchase cost p of $500 and you decide to value your inventory at the slightly higherrate…arrow_forwardExplain along with examples related to Freight Traffic Assignment Problems and vehicle routing problem in the logistics activities of manufacturing and service companies! Solve the following case study using the transportation method: Suppose there is a manufacturing company that produces and distributes its products to various customer locations across the country. This company has three production plants (Plant A, Plant B, and Plant C) located in different locations, and there are also five distribution centers (DC 1, DC 2, DC 3, DC 4, and DC 5) scattered across various regions. The company's goal is to determine the most efficient transportation routes for delivering products from the plants to the distribution centers, considering transportation costs and available capacities.arrow_forwardWaikato Farm Machinery Ltd (‘WFML’), is a well- established business, with the main base of its operations in Te Rapa, Hamilton. Its business is the importation and distribution of farm machinery such as tractors, loaders, diggers, bulldozers as well as farming equipment such as disc ploughs, rotovators, grain silos including machinery used by dairy farmers in milking sheds. The imported equipment is then sold at wholesale prices to smaller businesses in other centres in the Waikato and King Country regions, that on sell them to farmers. WFML has developed a formidable reputation as a supplier of such goods for at least two reasons. First, it imports machinery and equipment of the highest quality such as John Deere tractors from the United States and International Harvester tractors from Germany. Secondly, it has consistently stood by the goods it sells and efficiently attends to any difficulties experienced by retailers such as the repair of any defects. More importantly it is able to…arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.