Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

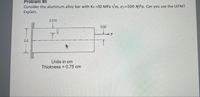

Transcribed Image Text:Problem #5

Consider the aluminum alloy bar with Kic=30 MPa vm, ay=500 MPa. Can you use the LEFM?

Explain.

0.375

0.50

P

2.0

1.

Units in cm

Thickness = 0.75 cm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A tendon tissue 100 mm long and having a square cross section 20 mm on an edge is pulled in tension with a load of 50 KN, and experiences an elongation of 0.10 mm. Assuming that the deformation is entirely elastic, calculate the elastic modulus of the issue Oa 125 OPa Ob 22 25 GPa OC 25 GPa Od 12.5 GPaarrow_forwardFor a large plate, the geometry factor, f, is 1.03. Suppose a steel casting alloy has a critical fracture toughness of 78,886 psi*in1/2. The steel will be exposed to a stress of 40,295 psi during service. Calculate the minimum size of an edge crack that will grow. Repeat the calculation for Al2O3 with a fracture toughness of 1,600 psi*in1/2. How many times larger is the minimum size edge crack in the steel versus the alumina?arrow_forward1. For the stress-strain curve shown below, please estimate the properties indicated. (a) Fracture Strain Please do your work on a separate sheet of paper, and put your answers in the boxes on the right. Be sure to include the proper symbol and units. Stress Strain 70 60 50 Stress (ksi) 240 30 20 10 70 0 0.000 60 50 Stress (ksi) 40 20 10 KULL 0 0.000 0.010 0.050 0.100 Strain (in/in) Stress Strain 0.020 0.030 Strain (in/in) 0.040 0.150 0.050 (b) Ultimate Tensile Stress (c) Fracture Stress (d) Proportional Limit (e) Elastic Modulus (1) Yield Stress (g) Tensile Toughness (Modulus of Toughness) (h) Modulus of Resiliencearrow_forward

- Determine the percentage of ductility of a metal alloy having the following tensile stress-strain diagram. Tensile stress-strain diagram 450 400 350 300 250 200 150 100 NO 50 0.05 0.1 0.15 0.2 0.25 0.3 0 35 0.4 Strain 300 EN Stress (Mpa)arrow_forwardRefer to imagearrow_forwardSuppose that an axle component of an automobile is fabricated from steel alloy with a plane strain fracture toughness of 45 MPa.m0.5 is exposed to a stress of 255 MPa and if the maximum internal half-length of the crack of the material is 3.2 mm, compute the dimensionless parameter (Y) of the material.arrow_forward

- Calculate the ductility of this steel alloy in %EL.arrow_forwardQ3: Two material were tested in tension, the first is aluminum alloy has stress-strain curve define by 300 MPa was fracture after 35% reduction in area. The other a copper alloy has stress-strain curve define by=100+120 MPa was fracture after 98% elongation. Which alloy have more toughness? Support your answer with the sketch.?arrow_forwardA metal bar of 0.5 meters diameter and a meter long is compressed in length by a force of 850KN. 1. For both the longitudinal and diametrical directions calculate the stress and the strain. 2. Change in diameter and length. 3. With a poisons ratio of 0.3 and modulus of elasticity of 185GPa calculate the bulk modulus 4. Using the relation between the bulk modulus and Young’s modulus find the modulus of rigidity.arrow_forward

- Calculate Strain energy for truss FC. Enter your answer in J to 2 decimal places.arrow_forwardQuestion 1 The S-N diagram for a titanium alloy is shown in the figure. Calculate the fraction of life consumed by the following sequence of loadings: 15,000 cycles at 80 MPa 120,000 cycles at 60 MPa 3,500,000 cycles at 50 MPa Maximum stress (ksi) 160 140 120 100 80 60 40 20 I 10³ 104 105 Cycles to failure 100 107arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY