Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

2 PARTs (A &B)- SOLVE CAREFULLY!! Please Write Clearly and Box the final Answer(s)

( Use images Below - Pay attention to numbers given)

Transcribed Image Text:The diagram depicts a simplified representation of a four-stroke combustion engine cycle, typically found in internal combustion engines.

1. **Intake Stroke (Labeled "1")**:

- The intake stroke begins when the piston moves down the cylinder's bore from top dead center (TDC) to bottom dead center (BDC).

- This movement creates a vacuum that allows the air-fuel mixture to enter the cylinder through the intake valve.

2. **Compression Stroke (Labeled "2")**:

- During the compression stroke, the piston moves back up the bore from BDC to TDC.

- The air-fuel mixture is compressed in the cylinder, increasing its temperature and pressure.

3. **Power Stroke (Labeled "3")**:

- The power stroke starts with the ignition of the compressed air-fuel mixture by a spark plug (in gasoline engines) or by the heat of compression (in diesel engines).

- The combustion generates a significant explosion and force, pushing the piston down from TDC to BDC.

4. **Exhaust Stroke (Labeled "4")**:

- During the exhaust stroke, the piston moves back up the cylinder from BDC to TDC.

- This movement expels the burnt gases from the combustion chamber through the exhaust valve, allowing the cycle to begin anew with the intake stroke.

The engine cycle is a continuous process, repeated consistently to convert fuel into mechanical energy, powering the vehicle.

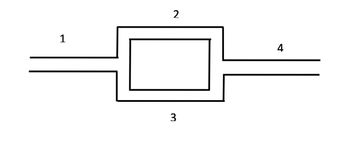

Transcribed Image Text:Consider a simple network of blood vessels shown in the figure. Segment 1 has a diameter of 1 cm, whereas segments 2, 3, and 4 have a diameter of 0.25 cm. All the segments have a length of 10 cm.

(a) If the total pressure drop Δp between the inlet and outlet is 100 mmHg, compute the blood flow rates in each segment, assuming representative values for whole blood viscosity and density.

(b) If the diameter of segment 2 is reduced to 0.22 cm, compute the new flow rates through each of the segments.

(Assume blood viscosity μ = 3.5 cP and density 1.060 g/cm³ and laminar flow.)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 6 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Q1: (20 marks) Write in summarat vou know abou fun me taleoems calculus. (20 marks) secondarrow_forwardOz Lawn Care Inc. manufactures and assembles lawnmowers that are shipped to dealers throughout the United States and Canada. Two different procedures have been proposed for mounting the engine on the frame of the lawnmower. PB (Minutes) UPB (Minutes )345798632 5 Is there a difference in the methods' mean time to mount the engines on the frames of the lawnmowers? The answer must be in handwriting. Please write your answer using a ball - point pen on plain paper. Submit your homework by uploading it to the canvas. Good Luck!arrow_forward

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY