Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

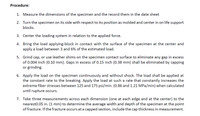

Transcribed Image Text:Procedure:

1. Measure the dimensions of the specimen and the record them in the date sheet

2. Turn the specimen on its side with respect to its position as molded and center in on life support

blocks.

3. Center the loading system in relation to the applied force.

4. Bring the load applying-block in contact with the surface of the specimen at the center and

apply a load between 3 and 6% of the estimated load.

5. Grind cap, or use leather shims on the specimen contact surface to eliminate any gap in excess

of 0.004 inch (0.10 mm). Gaps in excess of 0.15 inch (0.38 mm) shall be eliminated by capping

or grinding.

6. Apply the load on the specimen continuously and without shock. The load shall be applied at

the constant rate to the breaking. Apply the load at such a rate that constantly increases the

extreme fiber stresses between 125 and 175 psi/min. (0.86 and 1.21 MPa/min) when calculated

until rupture occurs.

7. Take three measurements across each dimension (one at each edge and at the center) to the

nearest0.05 in. (1 mm) to determine the average width and depth of the specimen at the point

of fracture. If the fracture occurs at a capped section, include the cap thickness in measurement.

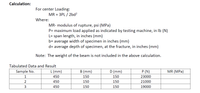

Transcribed Image Text:Calculation:

For center Loading:

MR = 3PL / 2bd?

Where:

MR- modulus of rupture, psi (MPa)

P= maximum load applied as indicated by testing machine, in Ib (N)

L= span length, in inches (mm)

b= average width of specimen in inches (mm)

d= average depth of specimen, at the fracture, in inches (mm)

Note: The weight of the beam is not included in the above calculation.

Tabulated Data and Result

Sample No.

L (mm)

B (mm)

D (mm)

P (N)

MR (MPa)

1

450

150

150

23000

2

450

150

150

21000

3

450

150

150

19000

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Problem 1.4. A tensile test was conducted on a mild steel bar. The following data was obtained from the test : (i) Diameter of the steel bar (ii) Gauge length of the bar (iii) Load at elastic limit (iv) Extension at a load of 150 kN. (v) Maximum load (vi) Total extension (vii) Diameter of the rod at the failure Determine : (a) the Young's modulus, = 3 cm = 20 cm = 250 kN = 0.21 mm = 380 kN = 60 mm - 2.25 cm. (c) the percentage elongation, and (b) the stress at lastic limit, (d) the percentage decrease in area.arrow_forwardA 42 meter solid shaft is under torsional loading 53 Nm. If in this application, the allowable shear stress for the material is 369 MPa. Calculate the required minimum diameter of the shaft: _____ mm ( input the value directly from your calculation before rounding it up to an engineering accepted diameter) Pay attention to units, and calculate your answer to one decimal place.arrow_forward2 please include scketcharrow_forward

- Solve it civil problemarrow_forwardA hot rolled steel tension test sample has a diameter of 6 mm and the original gage length of 30 mm. In a test to fracture, the stress and strain data below were obtained. Determine Generic Strain Value, %0.2 offset strain, and Calculated stress at %0.2 offset. Original diameter - 6mm Original Length - 30 mm Fracture diameter - 4.54 mmarrow_forwardYou must have to draw FBDarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning