Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

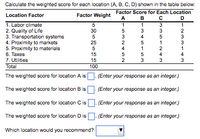

Transcribed Image Text:Calculate the weighted score for each location (A, B, C, D) shown in the table below:

Factor Score for Each Location

в

Location Factor

Factor Weight

A

D

1. Labor climate

2. Quality of Life

3. Transportation systems

4. Proximity to markets

5. Proximity to materials

6. Тахes

5

30

5

25

5

15

15

1

2

3

3

3

5

2

4

5

2

5

5

4

3

7. Utilities

Total

100

The weighted score for location A is

(Enter your response as an integer.)

The weighted score for location B is.

(Enter your response as an integer.)

The weighted score for location C is

s . (Enter your response as an integer.)

The weighted score for location D isD. (Enter your response as an integer.)

Which location would you recommend?

O33 1243

+514 3

532t52

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- don't use ai answer,i will 5 upvotesarrow_forwardLocation Fixed Cost Variable Cost A $100,000 $10 B $150,000 $7 C $200,000 $5 600 Annual 500 Cost ($000) 400 300 200 100 2 4 6 8 10 14 16 18 20 Q (000s of units) i. Plot the total cost curves in the chart provided above and identify the range over which each location would be best. ii. Use break-even analysis to calculate exactly the break-even quantity that defines each range.arrow_forwardWiebe Trucking, Inc., is planning a new warehouse to serve the western United States. Denver, Santa Fe, and Salt Lake City are under consideration. For each location, annual fixed costs (rent, equipment, and insurance) and average variable costs per shipment (labor, transportation, and utilities) are listed in the following table. Sales projections range from 550,000 to 600,000 shipments per year. Location Annual fixed cost Variable Costs per Shipment Denver $5,000,000 $4.65 Santa Fe $4,200,000 $6.25 Salt Lake City $3,500,000 $7.25 a. Plot the total cost curves for all the locations on a single graph. b. Which city provides the lowest overall costs? Thank you!!!arrow_forward

- A food manufacturer wants to locate a warehouse to serve its major customers. The customers, annual volume and the X and Y coordinates are shown in the table below. Customer Annual Volume X Coordinate Y Coordinate Judy Inc 25 3 7 Zac Supermarket 13 5 2 Harry Inc 6 8 4 Sky Productions 4 1 5 Using the centre of gravity location technique, determine the location coordinates that will minimize the transportation costs for their family of products.arrow_forwardThanks for help !arrow_forwardA company that is developing a strategy that entails obtaining location advantages for several of its different inputs A) would have each value chain activity replicated in each of its host country locations. B) would be pursuing a low cost strategy with economies of scale. C) would concentrate each value chain activity in the country in which can be performed most efficiently or effectively. D) would concentrate most of its value chain activities in its home country, where it is most familiar with the location. E) would implement a multi-domestic or multinational strategy.arrow_forward

- Q2k Audi is considering three locations A, B and C for the production of its new model SUV XL500. The objective is to choose the location with the lowest costs. The costs are measured as annual fixed costs plus the variable costs of the product. The following data has been collected for the three locations.< Region Fixed costs per year A B C 10 000 000 20 000 000 25 000 000 Variable cost per unit 1. at what level of production will C be the best choice? 2. at what production rate will A be the best choice? 3. at what level of production will B be the best choice? 2500 2000< 1000< The company's projected annual production in the new plant is 0-60 000 units.< Askarrow_forwardCan someone help me to fully solve the following problem showing all work. Thank youarrow_forwardLocation Score Factor (100 points each) Weight A B C Convenience 0.15 87 92 84 Parking facilities 0.20 73 83 93 Display area 0.18 90 89 96 Shopper traffic 0.27 90 90 93 Operating costs 0.10 85 89 88 Neighborhood 0.10 95 87 94 1.00 Click here for the Excel Data File a. Using the above factor ratings, calculate the composite score for each location. (Do not round Intermediate calculations. Round your final answers to 2 decimal places.) Location A Composite Score B C b. Determine which location alternative (A, B, or C) should be chosen on the basis of maximum composite score. Oc OB OA 13arrow_forward

- Silky Industries is looking for a location for its second telephone remanufacturing facility. Two cities are under consideration. The two most important location factors are: Factor A "availability of resources" and Factor B "availability of customers." However, the company is having great difficulty assigning relative weights to these factors. Assuming that the factor weights must sum to 100, what range of weights would make Blake the superior location? E Click the icon to view the factors table. The total weighted factor scores are the same for the following weights: Factor A=O and Factor B =D. As the weight of Factor B becomes Blake will be the superior location. (Enter your responses as whole numbers.) More Info Factor Score for Each Location Factor City Factor Weight Blake Irmo A. Availability of resources B. Availability of customers Total 8 10 9 6. 100 Print Donarrow_forwardc. A manufacturing firm is considering three potential locations for a new parts manufacturing facility. A consulting firm has assessed three sites based on the four factors supplied by management as critical to the location's success. Management-supplied the factor weights and the consultant team scores as seen in the table below. Scores are based on 50 = best. Location Factor Weight A B C Labor Climate 10 35 45 20 Taxes 30 30 40 40 Utilities 20 25 20 45 Wages 40 10 25 25 i. Which location should be selected and why?arrow_forwardProblem 8-9 (Static) Location Score Factor (100 points each) Weight A B Convenience 0.15 80 70 Parking facilities 0.20 72 76 Display area 0.18 88 90 90 Shopper traffic 0.27 94 86 Operating costs 0.10 98 90 Neighborhood 0.10 96 85 182820 C 60 92 80 82 75 1.00 Click here for the Excel Data File a. Using the above factor ratings, calculate the composite score for each location. (Do not round intermediate calculations. Round your final answers to 2 decimal places.) Location Composite Score A B 0arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.