thank you can do part C Determine the fraction conversion occurring in the pond & the tank separately & determine the overall conversion of the process.

thank you can do part C Determine the fraction conversion occurring in the pond & the tank separately & determine the overall conversion of the process.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

thank you can do part C

- Determine the fraction conversion occurring in the pond & the tank separately & determine the overall conversion of the process.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 3 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

ok, i think im starting to get it, is it like this

can you please help me more with part C

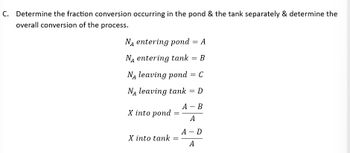

Transcribed Image Text:C. Determine the fraction conversion occurring in the pond & the tank separately & determine the

overall conversion of the process.

NA entering pond = A

NA entering tank = B

NA leaving pond = C

NA leaving tank = D

X into pond

X into tank

=

=

A - B

A

A - D

A

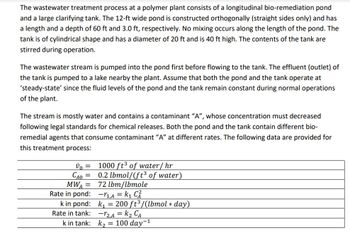

Transcribed Image Text:The wastewater treatment process at a polymer plant consists of a longitudinal bio-remediation pond

and a large clarifying tank. The 12-ft wide pond is constructed orthogonally (straight sides only) and has

a length and a depth of 60 ft and 3.0 ft, respectively. No mixing occurs along the length of the pond. The

tank is of cylindrical shape and has a diameter of 20 ft and is 40 ft high. The contents of the tank are

stirred during operation.

The wastewater stream is pumped into the pond first before flowing to the tank. The effluent (outlet) of

the tank is pumped to a lake nearby the plant. Assume that both the pond and the tank operate at

'steady-state' since the fluid levels of the pond and the tank remain constant during normal operations

of the plant.

The stream is mostly water and contains a contaminant "A", whose concentration must decreased

following legal standards for chemical releases. Both the pond and the tank contain different bio-

remedial agents that consume contaminant "A" at different rates. The following data are provided for

this treatment process:

vo=

CAO =

MWA =

Rate in pond:

k in pond:

Rate in tank:

k in tank:

1000 ft³ of water/ hr

0.2 lbmol/(ft3 of water)

72 lbm/lbmole

-₁,A = k₁ C²

k₁= 200 ft³/(lbmol * day)

-12,A = K₂ CA

k₂= 100 day-¹

Solution

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The