Advanced Engineering Mathematics

10th Edition

ISBN: 9780470458365

Author: Erwin Kreyszig

Publisher: Wiley, John & Sons, Incorporated

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

Constraints are in the statement and charts

![Blending Problems: This is another large class of problems in which linear programming is applied heavily. Blending is concerned with mixing different

materials called the constituents of the mixture (these may be chemicals, gasoline, fuels, solids, colors, foods, etc.) so that the mixture conforms to

specifications on several properties or characteristics. To model a blending problem as an LP, the linearity assumptions must hold. This implies that the

value for a characteristic for the constituents in the mixtures are the weighted average of the values of that characteristic for the constituents in the mixture;

the weights being the proportions of the constituents. As an example, consider a mixture consisting of 4 barrels of fuel 1 and 6 barrels of fuel 2, and suppose

the characteristic of interest is the octane rating (Oc.R). If linearity assumptions hold, the Oc.R of the mixture must be equal to (4 times the Oc.R of fuel 1

+ 6 times the Oc.R of fuel 2)/(4 +6). These linearity assumptions hold to a reasonable degree of precision for many important characteristics of blends of

gasolines, of crude oils, of paints, of foods, etc. That's why linear programming is used extensively in optimizing gasoline blending, in the manufacture of

paints, cattle feeds, beverages, etc. The decision variables in a blending problem are usually either the quantities or the proportions of the constituents.

Problem:

Three liquid mixtures are to be designed as provided in the table below to contain a special chemical called "Optim"

Optim [%]

45

35

65

30

Availability [gallons]

800

1000

Cost [$/gallon]

20

15

30

25

Material

700

1500

Minimum

Optim [%] Optim [%]

25

30

40

Required Amount

Igallons]

600

1200

Maximum

Selling Price ($/gallon)

70

Mixture

45

50

65

105

140

Y

900

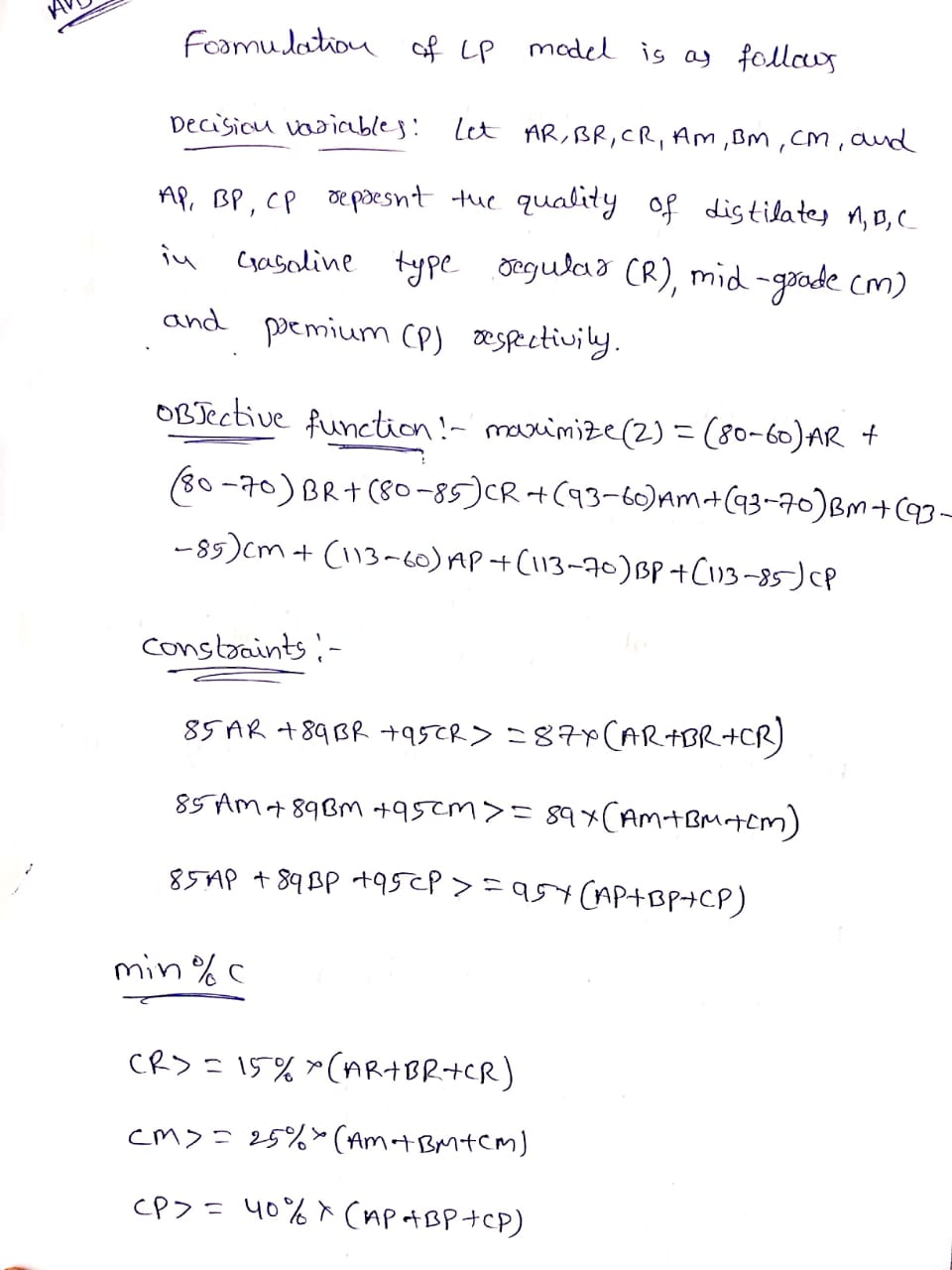

Formulate an LP model to determine the production plan that maximizes profit.

1234](https://content.bartleby.com/qna-images/question/388a9fab-648d-450d-a1a5-3932044f3fea/314a6a1d-6655-463b-8532-501b72fa5aaa/dvw1zo_thumbnail.jpeg)

Transcribed Image Text:Blending Problems: This is another large class of problems in which linear programming is applied heavily. Blending is concerned with mixing different

materials called the constituents of the mixture (these may be chemicals, gasoline, fuels, solids, colors, foods, etc.) so that the mixture conforms to

specifications on several properties or characteristics. To model a blending problem as an LP, the linearity assumptions must hold. This implies that the

value for a characteristic for the constituents in the mixtures are the weighted average of the values of that characteristic for the constituents in the mixture;

the weights being the proportions of the constituents. As an example, consider a mixture consisting of 4 barrels of fuel 1 and 6 barrels of fuel 2, and suppose

the characteristic of interest is the octane rating (Oc.R). If linearity assumptions hold, the Oc.R of the mixture must be equal to (4 times the Oc.R of fuel 1

+ 6 times the Oc.R of fuel 2)/(4 +6). These linearity assumptions hold to a reasonable degree of precision for many important characteristics of blends of

gasolines, of crude oils, of paints, of foods, etc. That's why linear programming is used extensively in optimizing gasoline blending, in the manufacture of

paints, cattle feeds, beverages, etc. The decision variables in a blending problem are usually either the quantities or the proportions of the constituents.

Problem:

Three liquid mixtures are to be designed as provided in the table below to contain a special chemical called "Optim"

Optim [%]

45

35

65

30

Availability [gallons]

800

1000

Cost [$/gallon]

20

15

30

25

Material

700

1500

Minimum

Optim [%] Optim [%]

25

30

40

Required Amount

Igallons]

600

1200

Maximum

Selling Price ($/gallon)

70

Mixture

45

50

65

105

140

Y

900

Formulate an LP model to determine the production plan that maximizes profit.

1234

Expert Solution

arrow_forward

Step 1

Step by stepSolved in 7 steps with 6 images

Knowledge Booster

Similar questions

- 1. Graph the system of inequalities representing the constraints.arrow_forwardDetermine graphically the solution set for the system of inequalities. x + y ≤ 5 0 ≤ x ≤ 2 y ≥ 0arrow_forwardWrite the constraint below as a linear inequality. A canoe requires 3 hours of fabrication and a rowboat 5 hours. The fabrication department has at most 112 hours of labor available each week. Let x be the number of canoes and let y be the number of rowboats. Choose the inequality that represents the given constraint. A. 3x+5y2112 B. 5x + 3y ≤ 112 C. 5x+3y2112 D. 3x+ 5y ≤ 112arrow_forward

- please help me outarrow_forwardI need explaination and spreadsheet with formulas and step to step interpretation please.....The attached are first two pages of required assisance and below is the rest of instructions please consider all of them:c. Suppose the CEO says, “Projects 3 and 4 must be undertaken but not both.”Describe the constraint.d. Suppose the CEO says, “Projects 4 cannot be undertaken unless projects 1 and 3also are both undertaken.” Describe the constraints. Hint: You may need to add more than one constraint for this part.3. [45pts] Multi-product Production Planning. Hart Manufacturing makes three products. Each product requires manufacturing operations in three departments: A, B, and C. The labor-hour requirements, by department, are as follows:Department Product 1 Product 2 Product 3A 1.50 3.00 2.00B 2.00 1.00 2.50C 0.25 0.25 0.25During the next production period, the labor-hours…arrow_forwardDefine the variables, determine the constraints and the objective function.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education

Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY

Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Advanced Engineering Mathematics

Advanced Math

ISBN:9780470458365

Author:Erwin Kreyszig

Publisher:Wiley, John & Sons, Incorporated

Numerical Methods for Engineers

Advanced Math

ISBN:9780073397924

Author:Steven C. Chapra Dr., Raymond P. Canale

Publisher:McGraw-Hill Education

Introductory Mathematics for Engineering Applicat...

Advanced Math

ISBN:9781118141809

Author:Nathan Klingbeil

Publisher:WILEY

Mathematics For Machine Technology

Advanced Math

ISBN:9781337798310

Author:Peterson, John.

Publisher:Cengage Learning,