Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

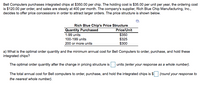

Transcribed Image Text:Bell Computers purchases integrated chips at $350.00 per chip. The holding cost is $35.00 per unit per year, the ordering cost

is $120.00 per order, and sales are steady at 400 per month. The company's supplier, Rich Blue Chip Manufacturing, Inc.,

decides to offer price concessions in order to attract larger orders. The price structure is shown below.

Rich Blue Chip's Price Structure

Price/Unit

$350

$325

$300

Quantity Purchased

1-99 units

100-199 units

200 or more units

a) What is the optimal order quantity and the minimum annual cost for Bell Computers to order, purchase, and hold these

integrated chips?

The optimal order quantity after the change in pricing structure is

units (enter your response as a whole number).

The total annual cost for Bell computers to order, purchase, and hold the integrated chips is $O (round your response to

the nearest whole number).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- XYZ Pharmaceuticals sells COVID testing kits. Calculate the Economic Order Quantity, or EOQ, if annual demand is 20,000 testing kits, inventory storage costs average 20 percent, the unit price per kit is $50, and ordering costs are $25.arrow_forwardA jewelry firm buys semiprecious stones to make bracelets and rings. The supplier quotes a price of $8.80 per stone for quantities of 600 stones or more, $9.20 per stone for orders of 400 to 599 stones, and $9.70 per stone for lesser quantities. The jewelry firm operates 230 days per year. Usage rate is 16 stones per day, and ordering costs are $45.a. If carrying costs are $2 per year for each stone, find the order quantity that will minimize total annual cost. (Do not round intermediate calculations, except for order quantities which should be rounded to the nearest whole number. Round your final answer to the nearest whole number.) b. If annual carrying costs are 20 percent of unit cost, what is the optimal order size? (Do not round intermediate calculations, except for order quantities which should be rounded to the nearest whole number. Round your final answer to the nearest whole number.) c. If lead time is 3 working days, at what point should the company reorder? (Do…arrow_forwardOne of your Taiwanese suppliers has bid on a new line of molded plastic parts that is currently being assembled at your plant. The supplier has bid $0.10 per part, given a forecast you provided of 400,000 parts in one year1. 500,000 in year 2; 700,000 in year 3. shipping and handling of parts from the supplier’s factory is estimated at $0.01 per unit. Additional inventory handling charges should amount to $0.006 per unit. Finally, administrative costs are estimated at $30 per month. Although your plant can continue producing the part, the plant would need to invest in another molding machine, which would cost $20,000. Direct materials can be purchased for $0.06 per unit. Direct labor is estimated at $0.05 per unit plus a 50% surcharge for benefits and, indirect labor is estimated at $0.008 per unit plus 50% benefit. Up-front engineering and design costs will amount to $40,000. Finally, management has insisted that overhead be allocated if the parts are made in-house at a rate of 100%…arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.