The reversible liquid phase reaction is carried out in a 12-dm3 CSTR with heat exchange. Both the entering temperature,T0, and the heat exchange fluid,Ta, are at 330 K. An equal molar mixture of inerts and A enter the reactor.

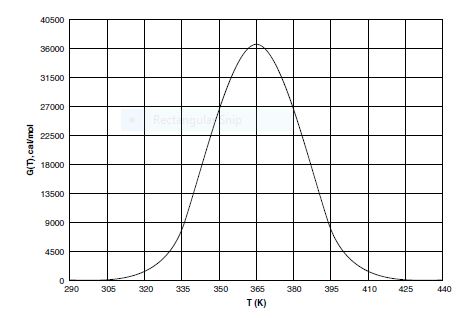

(a)Choose a temperature,T, and carry out a calculation to findG(T) to show that your calculation agrees with the corresponding G(T) value on the curve shown below at the temperature you choose.

(b)Find the exit conversion and temperature from the CSTR.X=_____T=_____.

(c)What entering temperatureT0would give you the maximum conversion?

T0= _____ X = _____

(d)What would the exit conversion and temperature be if the heat exchange system failed (i.e., U = 0)?

(e)Can you find the inlet ignition and extinction temperatures? If yes, what are they? If not, go on to the next problem.

(f)Use Preface Section I to ask another question.

Additional information

TheG(T) curve for this reaction is shown below

CPA = CPB = 100 cal mol K, C PI = 150 c al mol k = 0.001 h −1 at 300K with E = 30,000cal/mol

FA0 =10 mol h, CA0 = 1 mol dm 3 , v0 = 10 dm3/ h KC = 5,000,000 at 300 K

ΔHRx = −42,000 cal mol UA = 5000 cal/h/K

Step by stepSolved in 8 steps with 1 images

- QUESTION IN IMAGEEarrow_forwardA → B is carried out isothermally in a continuous reactor. Calculate both the CSTR and PFR reactor volumes necessary to consume 99% of A (i.e. CA = 0.01 CAO) when the entering molar flow rate is nA0 = 5 mol/h assuming the reaction -TA is 1. -TA = k 2. -TA = KCA 3. -TA = KC² The entering volumentric flow rate is V = 10 dm³/h. (Hint: Make use of equality n 40 No consider a Batch Reactor (BR) with a volume of V = 1000 dm³. Take the three reaction O rates from above and caclulate the times necessary to consume 99.9% of species A if the initial concentration is CAO 0.5 mol/dm³. with k = 0.05 mol h-dm3 with k = 0.0001 with k=3 dm³ mol-h :CAO V) =arrow_forwardYou are designing a reactor for a process that has the following decomposition reaction: A →D + 2F The rate law for this reaction is unknown and must be determined by an experiment. Since the reaction takes place in the liquid phase, you choose to build a CSTR reactor. You allow the reactor to fill to a certain volume, V, and then adjust the inlet and outlet volumetric flow rates to equal values, vo, to allow the system to reach steady state. Once the system is at steady state you measure the outlet concentration, CA. The residence time (t = V/v.) is increased by turning off the outlet flow, which allows the volume to increase, then setting the outlet flow to its original value and waiting until steady state is reached. You measure the concentration again and repeat this procedure multiple times to obtain the following table. Measurement 1 2 (ii) 234 in 3 5 Residence Time (min) 15.0 38.0 100 300 1200 Concentration (mol/L) 1.50 1.25 1.00 0.75 0.50 The inlet concentration (containing…arrow_forward

- The liquid phase reaction A + B → C follows an elementary law of velocity and occurs isothermally in a flow-through system. The rules for the feed streams of A and B are 2.0 mol/L before mixing. The volumetric flow rate of each stream is 5 dm3/min, and the inlet temperature is 300 K. The streams are mixed just before entering. Two reactors are available. One is a 200 dm3 CSTR, which can be heated to 77oC or cooled to 0oC; another is an 800 dm3 PFR, operated at 300 K, which cannot be heated or cooled. Note that k = 0.07 dm3 / mol.min at 300K and E = 20 kcal / mol. (A) What conversion would be achieved if the CSTR and PFR were operated at 300K and connected in series? And in parallel with 5 mols/min each? (B)Knowing that the operating times (loading, unloading, heating, cleaning, etc.) of the batch reactor is around 3 h, what volume of batch reactor would be necessary to process, per day, the same amount of species A as in reactors with Flow so as to achieve 90% conversion?arrow_forwardProblem 4 The reversible, exothermic, liquid phase, homogeneous reaction A ₹R is being carried out in two ideal CSTRs. Both reactors operate at 150°C. The molar flow rate of A entering the first CSTR is 55,000 mol/h, the concentration of A in this stream is 6.5 mol/L, and the concentration of R is zero. The fractional conversion of A in the outlet stream from the second CSTR is 0.75. The fractional conversion is based on the molar flow rate entering the first CSTR. The reaction is first order in both directions. The rate constant for the forward reaction is 1.3 h-¹ and the equilibrium constant based on concentration at 150°C is 10.0. If the volume of the second CSTR is 10,000 L, what is the required volume of the first CSTR?arrow_forwardQUESTION IN IMAGEEarrow_forward

- can you plz help with this followup questionarrow_forwardplease work out all the partsarrow_forwardWhich of the following situations can we consider a recycle stream for a process with reacting units? a. The reactants are highly miscible with the products. b. The feed is a mixture of valuable compounds known to be toxic to humans. c. Separation of reactants from the product requires state-of-the-art technology. d. Raw feed to the reactor is extremely valuable and is found to be non-toxic to humans.arrow_forward

- For the gas-phase reaction A = 2B operated at 1.0 bar: Initially, the reactor contains only A, at 1.0 mol. a. Prove that the reaction coordinate (moles of A consumed) equals the following: (see attactched image) b. Make a plot of the reaction coordinate versus temperature between 200 and 400 K for exothermic reaction conditions, making use of the van’t Hoff Equation. Data: Ka = 5.0 at 298 K, ΔHrxn0 = -50.0 kJ mol-1. Neglect the ΔCp term. c. Repeat Part b for endothermic conditions. Ka = 5.0 at 298 K, ΔHrxn0 = +50.0 kJ mol-1. Neglect the ΔCp term. d. If the reaction described in part b (i.e., exothermic conditions) were operated in a simple batch reactor, would the reaction mixture’s temperature increase, decrease, or remain constant as the reaction progressed? To maximize conversion, would you recommend that heat be added to, or removed from, the reactor?arrow_forwardA 1000 m3 lake is found to be contaminated with TCE (trichloroethane) that is potentially toxic to organisms. The concentration of TCE is 1.5 mg/L under steady-state conditions. Assume the lake behaves as a CSTR (completely stirred tank reactor). The decay of TCE is a first-order reaction with the rate constant of 2×10-6 s-1. If the source of TCE is closed off and the lake is to be flushed with clean water at a rate of 0.15 m3/s, how long will it take to lower the TCE concentration to 0.15 mg/L? Hint: You need to write the mass balance equation (VdC/dt=input rate-output rate-reaction rate) for this flushing (dilution) process and derive the concentration over time. The reaction rate for the first order kinetics is dC/dt= -kCV, where C is the pollutant concentration in the lake, t is the time, V is the lake water volume and k is the reaction rate constant. Group of answer choices A. 3 h B. 4.2 h C. 5.3 h D. 6.4 harrow_forwardillustrates an endothermic reactor applied in the production of methanol. Design a P&ID for this reactor by considering that the reactor temperature and pressure are needed to be maintained at a specific value.arrow_forward

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The