Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

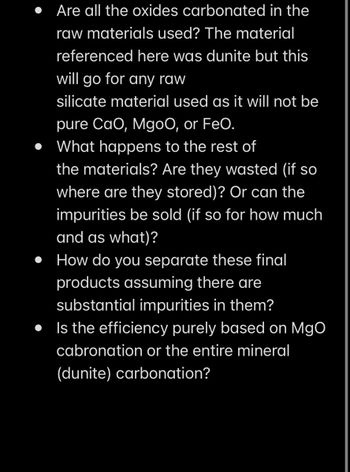

Transcribed Image Text:Are all the oxides carbonated in the

raw materials used? The material

referenced here was dunite but this

will go for any raw

silicate material used as it will not be

pure CaO, MgoO, or FeO.

• What happens to the rest of

the materials? Are they wasted (if so

where are they stored)? Or can the

impurities be sold (if so for how much

and as what)?

• How do you separate these final

products assuming there are

substantial impurities in them?

Is the efficiency purely based on MgO

cabronation or the entire mineral

(dunite) carbonation?

Expert Solution

arrow_forward

Step 1: First Step:

- Not all the oxides are carbonated in the raw materials used. The extent of carbonation depends on the type of mineral, its composition, and the conditions of the carbonation process. For example, dunite is a type of ultramafic rock that is composed primarily of olivine. Olivine is a magnesium-rich mineral that is easily carbonated, so most of the magnesium in dunite can be converted to magnesite (

). However, the iron and calcium in dunite are not as easily carbonated, so they may not be completely converted to carbonates.

- The rest of the materials that are not carbonated are called the residues. The residue can be stored or disposed of in a landfill. In some cases, the residue may have some value and can be sold. For example, the iron in the residues can be extracted and used to make steel.

- The separation of the final products from the residues can be done using a variety of methods, such as filtration, centrifugation, and precipitation. The specific method used will depend on the composition of the materials and the desired purity of the products.

- The efficiency of mineral carbonation is typically measured as the percentage of the magnesium oxide (MgO) in the raw material that is converted to magnesite (

). However, the efficiency can also be calculated based on the entire mineral (dunite) carbonation. In this case, the efficiency would take into account the amount of iron and calcium that are also converted to carbonates.

Here are some additional details about the carbonation of dunite:

- The carbonation process is typically carried out in a slurry of dunite and water. The slurry is heated to a high temperature, and

is bubbled through it. The

reacts with the magnesium in the dunite to form magnesite.

- The rate of carbonation depends on a number of factors, including the temperature, the concentration of,

and the surface area of the dunite particles.

- The efficiency of carbonation can be improved by using a fine-grained dunite and by operating the process at a high temperature and pressure.

- The residues from the carbonation process can be used to make bricks, concrete, and other building materials.

Step by stepSolved in 3 steps with 14 images

Knowledge Booster

Similar questions

- Can you reword this for me to have a better understanding: Plastic items like bottles and bags are made from polyethylene. Ethylene Oxide / Ethylene Glycol – becomes polyester for textile, and antifreeze for airplane engines and wings. Ethylene Dichloride – this, in turn, becomes a vinyl product used in PVC (polyvinyl chloride) pipes, siding, medical devices, and clothing. Styrene – synthetic rubber found in tires, as well as foam insulation.”arrow_forwardWhich of the following is one of the raw materials used for biodiesel production? short chain alcohols All of these animal fats vegetable oilsarrow_forwardPortland Cement is manufactured by the dry process conforming to the following specifications: Lime Saturation Ratio: - (CaO +1.5 Mg0 - 0.7 SO3)100 2.85 SiO₂ + 1.18Al2O3 + 0.65 Fe₂03 92 Iron Ratio = Al₂O3 = 2 Fe₂03 Magnesia, MgO should not exceed 1.5% and Sulfur as SO3 is 2.2% by wt Silica content of 24% by wt is acceptable The above cement is manufactured in a rotary kiln using limestone and clay as raw materials mixed in 75:25 proportion by weight. Analysis of Raw Materials Component Limestone,% Clay, % CaO 54.5 7.13 Fe₂O3 0.42 7.68 Al₂O3 0.83 17.15 SiO₂ 1.72 55.14 MgO 0.85 2.16 CO₂ 41.68 10.74 100 100 In the kiln, coal is added to supply heat of combustion. Coal contains 67.2%C, 4% H, 1.7% S, 2.2% 0, 2.6% H₂O and 22.3% ash. Its gross calorific value is 25.62 MJ/kg on a dry ash-free basis. Air supplied is 10% in excess at 27°C, 100 kPa and 75% RH. The stack gas contains 23.5% CO₂. The clinker is cooled and gypsum (essentially pure CaSO4) amounting to 3% its mass is added. The final…arrow_forward

- A feed stream containing 15% wt solids and 85% wt water is introduced in a certain process where the solids are being crushed. The crushed solids and preservatives are mixed in a 4:5 mass ratio and the mixture is heated to evaporate water. The residue has 1/3 water by mass. write step by step process: how many unknowns how many independent equations can be made? calculate the mass fraction of the solids in the product stream after producing 100 g of the product residue. Report your answer to 4 decimal places.arrow_forward2. An incinerator handles 80 kg per hour benefin (C13H16F3N3O4) and has a stack gas containing 5% oxygen by volume on a dry basis. Determine the percent excess air (both O2 and N2 gases as mol per hour and kg per hour) provided to the reactor. (Elemental weights: C=12 g, N=14 g, O=16 g, and F=19 g).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The