Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

thumb_up100%

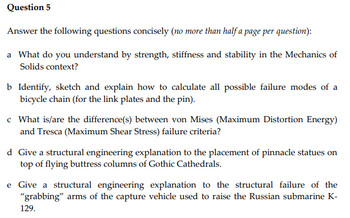

Transcribed Image Text:Question 5

Answer the following questions concisely (no more than half a page per question):

a What do you understand by strength, stiffness and stability in the Mechanics of

Solids context?

b Identify, sketch and explain how to calculate all possible failure modes of a

bicycle chain (for the link plates and the pin).

c What is/are the difference(s) between von Mises (Maximum Distortion Energy)

and Tresca (Maximum Shear Stress) failure criteria?

d Give a structural engineering explanation to the placement of pinnacle statues on

top of flying buttress columns of Gothic Cathedrals.

e Give a structural engineering explanation to the structural failure of the

"grabbing" arms of the capture vehicle used to raise the Russian submarine K-

129.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Considering Figure 20-8 (textbook), the torsion geometry parameter, Jw, for case 2 when b=6 and d=9 is most likely: 400.5 562.5 283.5 60.8 279.0 392.6 386.0 572.6 184.1arrow_forward1. For the stress-strain curve shown below, please estimate the properties indicated. (a) Fracture Strain Please do your work on a separate sheet of paper, and put your answers in the boxes on the right. Be sure to include the proper symbol and units. Stress Strain 70 60 50 Stress (ksi) 240 30 20 10 70 0 0.000 60 50 Stress (ksi) 40 20 10 KULL 0 0.000 0.010 0.050 0.100 Strain (in/in) Stress Strain 0.020 0.030 Strain (in/in) 0.040 0.150 0.050 (b) Ultimate Tensile Stress (c) Fracture Stress (d) Proportional Limit (e) Elastic Modulus (1) Yield Stress (g) Tensile Toughness (Modulus of Toughness) (h) Modulus of Resiliencearrow_forwardal stress and between which two pulleys does it occur and (6) take G = 80 GP. gle of rotation of pulley E relative to pulley A. %3D d = 100 d = 75 d = 75 d = 25 TA TB T Tc TD TE 1500 1000 1000 2000 Fro 0(All dimensions are in mm) Tp = 660 N.m, tad Tc = 275 N.m, TE = 110 N.m, %3D %3D anstugaa doe9 rebianos lleda aW TB 880 N.m, TA = 55 N.m %3Darrow_forward

- Part a and B pleasearrow_forwardplease helparrow_forwardFind the maximum normal stress in the bar pictured below. The parameter values are listed in the table. W2 P parameter value units དྷདྷ་ W1 30 mm W2 40 mm t 5 mm r 10 mm d 20 mm P 8 KN The maximum normal stress is σmax kd MPa. 080 BY NO SA 2021 Cathy Zupke Parrow_forward

- Compute the minimum vine diameter to provide a desired factor of safety of 1.7 against yield-type failure. Assume a yield stress of 300 MPa, and that the mass of the monkey is 65 kg. Hint Weight (N) = Mass (Kg) X g (9.81 m/s2)arrow_forwardA stainless steel is exposed to a temperature of 800 °C. What is the maximum allowable stress level for a rupture lifetime of 7 years? 103 T(20 + log t,)(°R-h) 25 30 35 40 45 50 |100 100 |10 10 1 12 16 20 24 28 103 T(20 + log t,)(K-h) Stress (MPa) Stress (103 psi)arrow_forwardi need the answer quicklyarrow_forward

- Factor of Safety =3 Material for Member AB is ASTM A36 Steel bb is cross-section of member AB. Distances AB=2m, BC-0.5m. 75.52° 30 (a) [30 marks] Calculate the maximum load, W, that can be safely hoisted before failure. (b) [5 marks] In (a) above. What shall be the mode of failure. Justify your answer. b=5cm Warrow_forwardA cylindrical steel bar 8 mm in diameter is loaded 1000 cycles per day with a load of 15560 N. How long until fatigue failure takes place? Note: stress = force/area Group of answer choices The bar should not fatigue. The bar will fail in one cycle. 100 days 1000 daysarrow_forwardplease helparrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY