Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

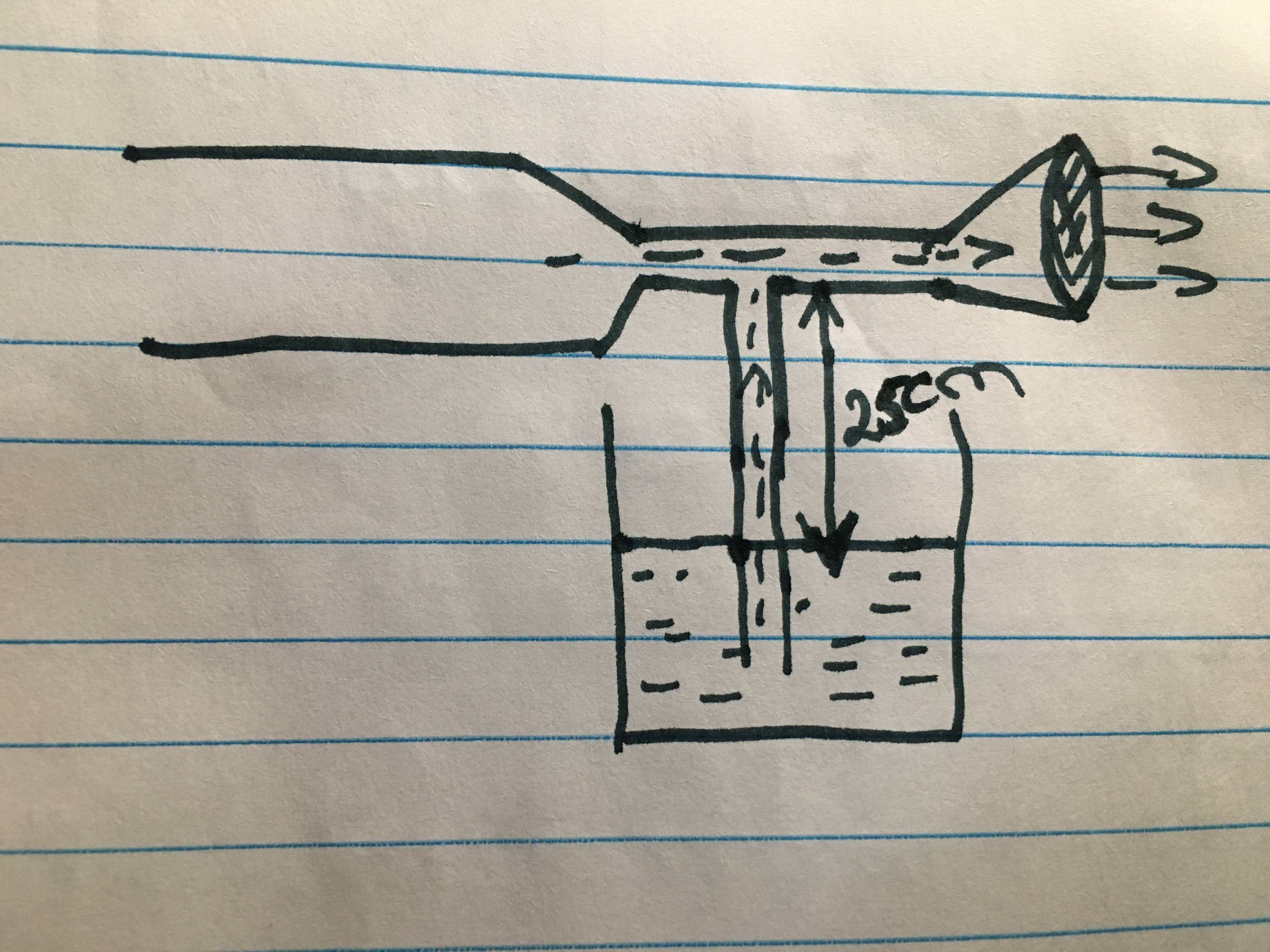

An insect repellent spray bottle is attached to the end of a 1.7cm diameter garden hose. Water from the hose goes through a 3.0 mm diameter constriction inside the top as shown in the image. The flow causes the pressure in the constricted area to drop, and the insect repellent is sucked up the tube 25 cm and mixed into the water stream. The insect repellent has a density of 1600 kg/m3. What is the minimum hose flow rate that will allow the insect repellent to be sucked up the tube and mixed with the stream? The water in the garden hose has a pressure of 50PSI. There is no viscosity.

Transcribed Image Text:250

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A capillary tube viscometer is being selected to measure viscosity of a liquid food. The maximum viscosity to be measured will be 230 cP and the maximum flow rate that can be measured accurately is 0.015 kg/min. If the tube length is 10cm and a maximum pressure of 25 Pa can be measured, determine the tube diameter to be used. The density of the product is 1000 kg/m3.arrow_forwardWorking for an engineering consultancy firm, your knowledge of fluid dynamics is required to design a new safety feature for a high-pressure air line in a factory. The air line takes the form of a cylindrical pipe of diameter 150 mm, which is designed to operate between 0.45 MPa and 0.76 MPa. At the end of the pipe a burs9ng disk is placed so that, if the pressure exceeds the maximum opera9ng pressure, the air is vented to atmosphere rather than over-pressuring the chemical reac9on vessel (Figures 4a and 4b). In this ques9on, you should treat the flow as quasione-dimensional and inviscid. The air in the surrounding atmosphere is at 101 kPa and 298 K. a) You have a choice of five disks which can withstand the following forces across them before burs9ng: 10.5 kN, 11.0 kN, 11.5 kN, 12.0 kN, 12.5 kN. Which of these burs9ng disks would you recommend, and why? b) Due to an over-pressurisa9on of the air line, the disk bursts at 9me t = 0. At what pressure in the air line will this occur? c)…arrow_forwardConsider the flow of a fluid with viscosity m through a circular pipe. The velocity profile in the pipe is given as u(r) = umax(1 - rn/Rn), where umax is the maximum flow velocity, which occurs at the centerline; r is the radial distance from the centerline; and u(r) is the flow velocity at any position r. Develop a relation for the drag force exerted on the pipe wall by the fluid in the flow direction per unit length of the pipe.arrow_forward

- A 1 cm in diameter vertical pipe has a pressure difference of 200 kPa with liquid Sodium (Na) flowing through. What is the flow rate through the pipe?arrow_forwardOil with a density of 850 kg/m3 and kinematic viscosity of 0.00062 m2/s is being discharged by a 8-mm-diameter, 40-m-long horizontal pipe from a storage tank open to the atmosphere. The height of the liquid level above the center of the pipe is 4 m. Disregarding the minor losses, determine the flow rate of oil through the pipe.arrow_forwardA capillary tube is immersed vertically in a water container. Knowing that water starts to evaporate when the pressure drops below 3 kPa, determine the maximum capillary rise and tube diameter for this maximum-rise case. Take the contact angle at the inner wall of the tube to be 6° and the surface tension to be 1.00 N/m. The maximum capillary rise is m. The tube diameter for the maximum rise is um.arrow_forward

- As shown in figure below, oil can be siphoned from a tank using a flexible hose, provided that the end of the hose at Point B, is below the free surface in the tank at Point A. The maximum elevation of the hose is at Point C. Oil is being siphoned from the tank through a constant-diameter hose. The end of the siphon at Point B is 6.71 meters below the oil top surface level of the tank at Point A. If the gauge pressure at Point C is 90.257 KPa and the density of oil is 890 fraction numerator k g over denominator m cubed end fraction , the vertical distance between Point C and Point B in meters isarrow_forwardConsider a U-tube whose arms are open to the atmosphere. Now, water (p = 1000 kg/m³) is poured into the U-tube from one arm and light oil (p = 790 kg/m³) from the other. One arm contains 70-cm-high water, while the other arm contains both fluids with an oil-to- water height ratio of 3. Determine the height of each fluid in that arm. Oil U 70 cm -Water The height of water in that arm is The height of oil in that arm is m. m.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY