Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

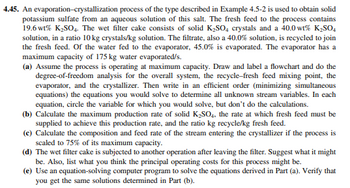

Transcribed Image Text:4.45. An evaporation-crystallization process of the type described in Example 4.5-2 is used to obtain solid

potassium sulfate from an aqueous solution of this salt. The fresh feed to the process contains

19.6 wt% K₂SO4. The wet filter cake consists of solid K₂SO4 crystals and a 40.0 wt% K₂SO4

solution, in a ratio 10 kg crystals/kg solution. The filtrate, also a 40.0% solution, is recycled to join

the fresh feed. Of the water fed to the evaporator, 45.0% is evaporated. The evaporator has a

maximum capacity of 175 kg water evaporated/s.

(a) Assume the process is operating at maximum capacity. Draw and label a flowchart and do the

degree-of-freedom analysis for the overall system, the recycle-fresh feed mixing point, the

evaporator, and the crystallizer. Then write in an efficient order (minimizing simultaneous

equations) the equations you would solve to determine all unknown stream variables. In each

equation, circle the variable for which you would solve, but don't do the calculations.

(b) Calculate the maximum production rate of solid K₂SO4, the rate at which fresh feed must be

supplied to achieve this production rate, and the ratio kg recycle/kg fresh feed.

(c) Calculate the composition and feed rate of the stream entering the crystallizer if the process is

scaled to 75% of its maximum capacity.

(d) The wet filter cake is subjected to another operation after leaving the filter. Suggest what it might

be. Also, list what you think the principal operating costs for this process might be.

(e) Use an equation-solving computer program to solve the equations derived in Part (a). Verify that

you get the same solutions determined in Part (b).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps with 5 images

Knowledge Booster

Similar questions

- What is meant by loading in adsorption?arrow_forwardIn distillation, what is meant by reflux, boilup, rectification section, and stripping section?arrow_forwardDesribe the general composition, properties, uses, applications of the following materials and their reasons: HSLA steel Gray cast ironarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The