Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

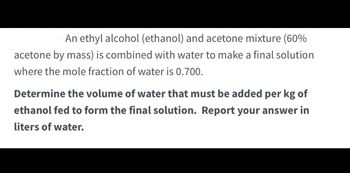

Transcribed Image Text:An ethyl alcohol (ethanol) and acetone mixture (60%

acetone by mass) is combined with water to make a final solution

where the mole fraction of water is 0.700.

Determine the volume of water that must be added per kg of

ethanol fed to form the final solution. Report your answer in

liters of water.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Similar questions

- A 60 - 40 mixture (by moles) of A and B is separated into two fractions. A flowchart of the process is shown here. 100.0 mol 0.60 mol A/mol 0.40 mol B/mol 50.0 mol 0.95 mol A/mol 0.05 mol B/mol 12.5 mol A 37.5 mol B It is desired to achieve the same separation with a continuous feed of 1250 lb-moles/h. Scale the flowchart accordingly.arrow_forwardA stream of 100 kmol/h of a binary mixture of Acetone and Methanol contains 45 mol% of the most volatile and needs to be distilled to provide solutions of its components in high purity. A continuous column of dishes with reflux (fractional distillation) will be used for the service, where the mixture will be fed as a saturated liquid. It is desired to obtain a liquid solution of the most volatile with 95% in mol as the top product. Thus, a total capacitor will be used. As a bottom product, 90% by mol of the least volatile should be obtained. The column will be operated at about 1atm. A reflux ratio of 3 mol fed back for each mol of distillate withdrawn will be used. Using the McCabe-Thiele method, one asks: a) What is the distillate output from the column? What is the bottom of the column production? b) How many equilibrium stages would the column have? How many ideal dishes would be needed for the service? In that case, what would be the number of the feeding plate? c) If we used a…arrow_forwardIn a process producing jam (C1), 1000 kg of crushed fruit (CF) containing 14 wt% soluble solids (SS) and the balance water (W) is mixed in a mixer with 1220 kg of sugar and 2.5 kg of pectin. The resultant mixture is then evaporated in a kettle to produce a jam containing 6.7 wt% soluble solids.a. Draw and completely label the process flow diagram of the process b. Perform the degree of freedom analysis c. Calculate the mass (kg) and the mass composition (wt%) of the jam produced. Also calculate the kg water evaporated. (2089.6 kg jam produced, 6.7 wt% soluble solids, 58.4 wt% sugar, 0.12 wt% pectin, 34.78 wt% water, 132.9 kg water evaporated)arrow_forward

- 300 g of baking soda (solid) and 8 kg of vinegar (liquid) mixture react to form 192 g of sodium acetate along with water and carbon dioxide gas: NaHCO3 + HC2H302 - Nac2H302 + H20 + CO2 If the desired product is sodium acetate (NaC2H302). Calculate the a. molality of baking soda, b. mole percentage of baking soda, c. percentage yield of desired productarrow_forwardNitroglycerine (C3H5N3O9) is a very sensitive explosive used to make dynamite. If all of the nitrogen in this compound is released as N2, calculate the total mass of nitrogen gas released when 3.81 kg of nitroglycerine is detonated.arrow_forwardYou wash a Coplin jar with soap and water to ensure it is clean before running a TLC. You should take the time to make sure there are no drops of water left inside the jar. (True or False)The solvent that the sample is dissolved in must always be the same as the eluant when running a TLC plate.(True or False)You are preparing to spot a sample of crude benzophenone and pure benzophenone on two separate lanes of a TLC plate to analyze the crude product. You can use the same TLC spotter for both samples.(True or False)After running a TLC plate to compare crude benzophenone and pure benzophenone you determine you need to prepare a new TLC plate and rerun the TLC. You can use the same spotter for the crude benzophenone as you did for the first TLC plate.(True or False)arrow_forward

- A mixture is 12.5 weight % propylene (C3H6), 12.5 weight % benzene (C6H6), and 75.0 weight % cumene (C9H12). For the mixture described above, calculate the average molecular weight of the mixture (g/mol).arrow_forwardABS plastic is a polymer consisting of three monomer units: acrylonitrile (C₃H₃N), butadiene (C₄H₆), and styrene (C₈H₈). A sample of ABS plastic contains 12.9% N by mass. It took 1.56 g of Br₂ to react completely with a 2.00 g sample of ABS plastic. Bromine reacts 1:1 (by moles) with the butadiene units in the polymer and nothing else, so bromination is a method for determining the quantity of butadiene in the polymer. What is the percent by mass of styrene in the polymer?arrow_forwardOne of the best ways to reduce or eliminate hazardous waste is through source reduction. Generally, this means using different raw materials or redesigning the production of excess to eliminate the generation of hazardous byproduct. As an example, consider the following countercurrent extraction process to recover xylene from a stream that contains 10% xylene and 90% solids by weight. S' Clear liquid (no solids) F1 0.9 Solids Product stream 100% Benzene 1000 kg/hr Waste stream 0.9 Solids (no solids) Unit 1 Unit 2 0.9 Solids 1 0.1 Xylene Foed 2000 kg/hr The stream from which xylene is to be extracted enter Unit 2 at a flow rate of 2000 kg/h. To provide a solvent for the extraction, pure benzene is fed to Unit 1 at a flowrate of 1000 kg/h. The mass fractions of the xylene in the solids stream (F) and clear liquid stream (S) have the following relations: 10XF Kxylene xylene and 10x, Kxylene = Xxylene a) Determine the benzene and xylene concentrations in all of the streams. b) What is the…arrow_forward

- An aqueous solution of NaCl has a concentration of 10.0 wt% (w/w) NaCl with a density of 1.178 g/cm3. Calculate the following: mole fraction of NaCl and water. concentration of NaCl as lbm/ft3. the average molecular weight of the solution. (Molecular weight: Na = 23 g/gmol; Cl = 35.5 g/gmol; H = 1 g/gmol; O = 16 g/gmol)arrow_forwardTo make an 18.76% (w/w) solution, what volume (mL) of solvent would be needed for a solution that contains 12.58 grams of solute? The density of solvent is 1.246 g/mL and the molecular weight of the solute is 54.12 g/mol. 38.2 mL 54.5 mL 43.7 mL O 21.8 mL Next by ProProfs Create a Quiz rch 24% 27°C Sunny O D E 4)) G ENarrow_forward4. [Scrubber]. A coal-fired combustion system produces flue gas that contains particulate matter. To reduce the amount of particles, the flue gas is treated in a scrubber. The measurement of the mass and size of the particles at the inlet and outlet of the scrubber yielded the size distribution data given in the following table: Particle diameter [um] (size interval: dlower → dupper) 0.10.25 0.25 → 0.5 0.5 → 1.0 1.0→2.0 2.05.0 Formulas for question 4: . Particle mass at scrubber inlet [mg] 623 55.4 12.6 8.9 7.1 5.0 10 7.7 10 →30 6.6 30→ 50 4.3 The mass of particles in each size interval was measured on a basis of 1 m²³. 31.4 33.2 123 a) What is the overall efficiency of the scrubber? [Ans: noverall 96.7 %] b) Calculate the collection efficiency (na,i) of the scrubber and the particle geometric average diameter (dpi) for each size interval. Create a graph showing the variation of na,i with dp,i. (PTO) efficiency: nd,i (%) = - 394 775 1055 c) Calculate the mass-average diameter of the…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The