Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

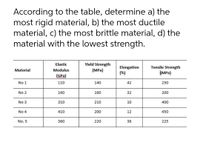

Transcribed Image Text:According to the table, determine a) the

most rigid material, b) the most ductile

material, c) the most brittle material, d) the

material with the lowest strength.

Elastic

Yield Strength

Tensile Strength

Elongation

(%)

Material

Modulus

(MPa)

(MPA)

(GPa)

No 1

110

140

42

250

No 2

160

160

32

200

No 3

310

210

10

400

No 4

410

200

12

450

No. 5

360

220

36

225

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- MENG222 Strength of Materials Please give me abAbstract about f Experiment: Torsion Test All thank and appreciation ?? ?arrow_forwardGiven the following data for five different materials answer parts A B C D E & F with an explanationarrow_forwardThe engineering stress-strain curve below was obtained for a precipitation hardened Aluminum alloy. What is the approximate Yield Strength for this alloy in psi? Engineering Stress Based on Original Area (psi) 50,000 45,000 40,000 35,000 30,000 25,000 20,000 15,000 10,000 5,000 0 O 0.02 0.04 0.06 Aluminum 6061-T6 0.08 0.1 0.12 Engineering Strain (in/in) 0.14 X 0.16 0.18arrow_forward

- In the image demonstrated, what does E represent? A) Modulus of elasticity B) Olds modulus C) Proportional limit D) Elongationarrow_forwardIn the graph, the module of toughness can be shown to be represented by: A) The area associated with necking B) The rectangular area label yielding C) The triangular area in the elastic region D) The sum of the entire shaded area under the curvearrow_forwardPlease annotate the attached stress strain graph of 0.9% carbon steel to show the different phases. From the graph work out the following: 1) modulus of elasticity 2) tensile strength 3) the ductility in % elongation 4) yield strength at a strain offset of 0.002arrow_forward

- Please help with all, and desbribe how the table is used, thank you in advance! Will give thumbs uparrow_forwardWhich one(s) of the following about G, shear modulus of elasticity of a material are correct? select all which are correct. G is also called the modules of rigidity. G is related to the modulus of elasticity E and Poisson’s ratio . G is usually smaller than Young's modulus E for the same material. G is the ratio of shear stress to shear strain when the material's proportional limit in shear has not been exceeded.arrow_forwardDetermine the percentage of ductility of a metal alloy having the following tensile stress-strain diagram. 600 500E 400 500 300 400E 300 200 200 100 100 0.000 0.002 0.004 0.006 Strain 0.00 0.04 0.08 0.12 0.16 0.20 Strain EN Stress (MPa) Stress (MPa)arrow_forward

- Review Data taken from a stress-strain test for a ceramic are given in the table. The curve is linear between the origin and the first point. No elements selected a(ksi) 50 + 40 - 30 Figure 1 of 1 20 10 + o (ksi) € (in./in.) ex 10(in./in.) 0.5 1.0 1.5 2.0 2.5 33.2 0.0006 45.5 0.0010 Press (ENTER) to select this element. Press ESC) to return to the main menu. Press CTRL+Q) to quit the application. 49.4 0.0014 51.5 0.0018 53.4 0.0022arrow_forwardQ3 : Rank the magnitudes of the moduli of elasticity for the following hypothetical X, Y, and Z materials from the greatest to the least.The appropriate A, B, and n parameters for these three materials are tabulated below; they yield EN in units of electron volts and r in nanometers: Material A В n 2.5 2.0 x 10-5 8. Y 2.3 8.0 x 10-6 10.5 Z 3.0 1.5 x 10-5 9.arrow_forwardo (MPa) 900 800 700 600 500 400 300 200 100 0 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 Question 1 Which ONE of the following descriptions is TRUE for this material? Its yield stress is approximately 720 MPa. It is a brittle material. It is a ductile material. Its ductility as a percentage elongation is approximately 0.6%. Earrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY