Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Please see attached screenshots. thank you!

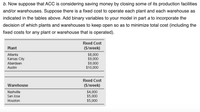

Transcribed Image Text:Aberdeen Computer Corp. (ACC) is located in Aberdeen, Washington. The company has developed the WebSurfer, a cost-effective email and web-surfing appliance. Manufactured at four plants located in Atlanta, Kansas City, Aberdeen, and Austin, these products are shipped to three warehouses in Nashville, San Jose, and Houston after production. ACC distributes WebSurfers to major retailers such as Sears, Best Buy, Fry’s, Comp USA, and Office Max through these warehouses. Below is the table containing shipping costs from each plant to each warehouse, including production cost per unit and weekly production capacity at each plant.

**Table: Plant Shipping Costs, Production Costs, and Capacity**

| Plant | Shipping Cost ($/unit) | | | Production Cost ($/unit) | Capacity (units/week) |

|-------------|------------------------|-----------|----------------|--------------------------|-----------------------|

| | Nashville | San Jose | Houston | | |

| Atlanta | $30 | $40 | $50 | $208 | 200 |

| Kansas City | $25 | $45 | $40 | $214 | 300 |

| Aberdeen | $45 | $30 | $55 | $215 | 250 |

| Austin | $30 | $50 | $30 | $210 | 400 |

The next table provides data on shipping cost from each warehouse to each customer, variable cost per unit moved through warehouses, maximum capacity for each warehouse, and weekly customer demand.

**Table: Warehouse Shipping Costs and Demands**

| Warehouse | Shipping Cost ($/unit) | | | | | Variable Cost | Capacity (units/week) |

|-----------|------------------------|---------|-----------|-----------|-----------|---------------|------------------------|

| | Best Buy | Fry’s | Comp USA | Office Max| | ($/unit) | |

| Nashville | $40 | $45 | $30 | $25 | $20 | $4 | 300 |

| San Jose | $15 | $50 | $25 | $15 | $40 | $5 | 500 |

| Houston | $50 | $35 | $15 | $40 | $50 |

Transcribed Image Text:### Decision-Making for Cost Optimization

**Scenario:**

ACC is considering ways to reduce costs by potentially closing some production facilities and/or warehouses. Each plant and warehouse incurs a fixed operating cost weekly.

**Objective:**

Incorporate binary variables into your model to determine which plants and warehouses should remain open to minimize total cost, which includes fixed costs for any operational facility.

### Fixed Costs for Facilities:

#### Plants:

- **Atlanta**: $8,000 per week

- **Kansas City**: $9,000 per week

- **Aberdeen**: $9,000 per week

- **Austin**: $10,000 per week

#### Warehouses:

- **Nashville**: $4,000 per week

- **San Jose**: $5,000 per week

- **Houston**: $5,000 per week

By evaluating these fixed costs, ACC can make informed decisions about which facilities to operate in order to achieve cost efficiency.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 4 images

Knowledge Booster

Similar questions

- What does research suggest about the relative cost of retaining current customers versus acquiring new customers? Question options: Acquiring new customers costs roughly the same as retaining current ones. Acquiring new customers can cost several times as much as retaining current ones. Acquiring new customers costs slightly less than retaining current ones. Retaining current customers can cost several times as much as acquiring new ones. Acquiring new customers costs slightly more than retaining current ones.arrow_forwardQuestion needed very simple answer and no min word limitation. There are Elvis clubs around in the world. There is an annual Elvis members gathering in Parkes, NSW every January. What sort of personality would join an Elvis Club?arrow_forwardQUESTION 1 Which levels of needs assessment should be conducted prior to recommending an HRD intervention? Task, Diagnostic, and Competency Organization, task, and person Organization, Job, and Competency Analytic, Team, and individual QUESTION 2 What is a needs assessment? A process by which an organization determined how to deliver a training solution A method used to identify and articulate an organization’s HRD needs A method used to determine the training needs to address individual performance challenges A method employed to articulate an organization’s need for talent development QUESTION 3 Why is it necessary to conduct a needs assessment? To make certain the recommended HRD solution produces desired outcomes To confirm the training suggested by the person who requested training To build a business case for purchasing training built by a well-known learning &…arrow_forward

- 5X Is it ethical to apply disciplinary action in cases of ongoing absenteeism and tardiness due to family responsibilities? What other approach could be used? Entriesarrow_forwardCAN I GET A MORE IN MORE DETAILS ANSWER WITH DIFFERENT POINTS I HAVE MENTIONarrow_forwardWhen Amy helps to ensure fair and equitable treatment for her employees regardless of their personal background or circumstances, she is performing a(n) ________. Question 16 options: 1) strategic role. 2) tactical role. 3) administrative role. 4) employee advocate role.arrow_forward

- Which of the following occurs when the general manager responds to negative comments from a guest and handles the issue immediately? Question 11 options: a) Accountability b) Empowerment c) Benchmarking d) Authorityarrow_forwardbuilding project failures Exactracted from (News 24,2021) with reference to case study provided the 1.1criically discuss the primary reason contributing to failure of building 1.2 in reference to the reasons provided in question 1.1 above, discuss the impact of project failures and suggest solution that can be considered by project managers to mitigate against future project failures 1.3 with reference to construction project,critically discuss the contents of a project quality plan. your response should refer to reference to revent examplesarrow_forwardWhich of the following processes is used in social media monitoring? Question 4 options: a) Crowdsourcing b) Cold calling c) Personal selling d) Sentiment analysisarrow_forward

- multiple choice: Under what circumstances should a food service employee who is ill report to work? A. Under a doctor's supervision. B. When he or she has been on medication for 24 hours. C. Only when the operation is severely understaffed. D. Employees who are ill should not report to work.arrow_forwardDevelop a sample print AD for the brand Illiminate that is an automotive company that provides clothing and vehiclesarrow_forward4arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.