Concept explainers

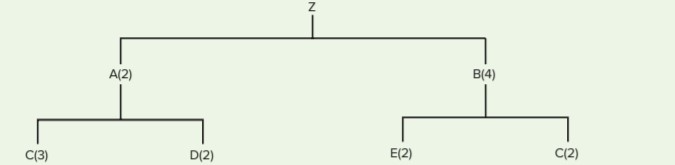

a. One hundred twenty units of end item Z are needed at the beginning of week 7. Prepare a material requirements plan for component C. Take into account that on hand there are 40 units of Z,

70 units of A, 100 units of B, and 30 units of C. Also, there is a

component C in week 4. Lead times are two weeks for Z and B, and one week for the other components. Lot-for-lot ordering will be used for all items

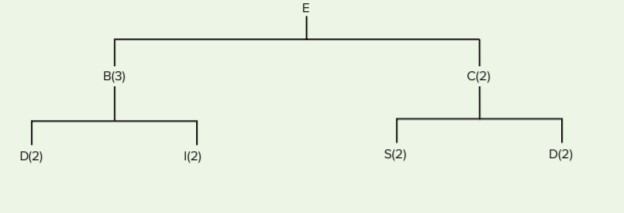

b. Ninety-five units of end item E are needed at the beginning of week 7. Prepare a material requirements plan for component D. Take into account that 5 units of E are currently on hand, as well as

50 units of B, 100 units of C, and 80 units of D. Also, 30 units of C have been outsourced and are

expected to arrive in week 4. Lead times are two weeks for E and C, and one week for the other

components. Assume lot-for-lot ordering except for D, where multiples of 40 must be used.

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 8 images

- b) Prepare a master schedule based on the following information: Week: 1 2 3 5 Forecast 120 100 150 Orders 70 90 60 Initial inventory=100 Batch size = 200 4 80 30 80 20 6 100 10 7 120 0 8 110 0arrow_forwardThe BOM for product A is shown in Figure 2, and data from the inventory records are shown in Table 3. In the master production schedule for product A, the MPS start row has 150 units in week 3 and 300 in week 5. Develop the material requirements plan for the next 6 weeks for items B, C, and D.arrow_forward1.arrow_forward

- You are supposed to find the gross requirements for all of them.arrow_forwardGiven the following MRP matrix for Item D, the planned order receipt for period 4 is ITEM: D Period Lot Size: Mul 100 LT: 1 1 2 3 4 6 Gross Requirements Schedule Receipts Project on Hand Net Requirements Planned Order Receipts 60 90 150 150 180 270 120 120 Planned Order Releases 100 200 220 DELLarrow_forwardProduct A is made from components B and C. Item B, inturn, is made from D and E. Item C also is an intermediateitem, made from F and H. Finally, intermediate item E ismade from H and G. Note that item H has two parents. Thefollowing are item lead times:a. What lead time (in weeks) is needed to respond to a cus-tomer order for product A, assuming no existing invento-ries or scheduled receipts?b. What is the customer response time if all purchased items(i.e., D, F, G, and H) are in inventory?c. If you are allowed to keep just one purchased item instock, which one would you choose?arrow_forward

- Given the following MRP matrix for Item D: The planned order receipt for period 6 isarrow_forward3. Item Z has a lead time of two weeks; A, B, C and D take one week each and E takes 3 weeks. Fifty units of Z are required in period 10. Assume that there is currently no inventory on hand of any of these items. Consider the following Bill of material and develop an MRP schedule for A, B, C, D and E showing gross and net requirements and order releases and order receipt dates. Assume Lot-for-lot ordering. C(3) A(2) Z D(4) E(2) B(4) Level 0 1 2 3arrow_forwardCompare and contrast the meaning of the word lead time in a typical EOQ and an MRP scheme.arrow_forward

- One unit of A is made of one unit of B and one unit of C. B is made of four units of C and one unit each of E and F. C is made of two units of D and one unit of E. E is made of three units of F. Item C has a lead time of one week; Items A, B, E, and F have two-week lead times; and Item D has a lead time of three weeks. Lot-for-lot (L4L) lot sizing is used for Items A, D, and E; lots of size 50, 100, and 50 are used for Items B, C, and F, respectively. Items A, C, D, and E have on-hand (beginning) inventories of 15, 55, 100, and 10, respectively; all other items have zero beginning inventory. We are scheduled to receive 10 units of A in Week 1, 100 units of C in Week 1, and 100 units of D in Week 3; there are no other scheduled receipts.If 50 units of A are required in week 10, use the low-level-coded bill-of-materials (product structure tree) to find the necessary planned-order releases for all components. (Leave the cells blank, whenever zero (0) is required.)arrow_forwardWhat is another common name for the bill-of-materials?arrow_forwardMRP Logic 13. Item A has a gross requirement for 1,000 in week 5. There are currently 300 of the item on hand, with a scheduled receipt of 100 items in week 2. The order quantity is lot for lot, and there is a two-week lead time. Complete the MRP record for item A.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.