Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

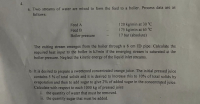

Transcribed Image Text:a. Two streams of water are mixed to form the feed to a boiler. Process data are as

follows:

120 kg/min at 30 °C

175 kg/min at 65 °C

17 bar (absolute)

Feed A

Feed B

Boiler pressure

The exiting stream emerges from the boiler through a 6 cm ID pipe. Calculate the

required heat input to the boiler in kJ/min if the emerging stream is saturated at the

boiler pressure. Neglect the kinetic energy of the liquid inlet streams.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 6 steps with 7 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 5. A steam power plant operates on the cycle below. Complete the table. -2200.0 kJ/kg Ideal Turbine Work Turbine Efficiency Ideal Pump Work Pump Efficiency 0.75 100.0 kJ/kg 0.80 4000.0 kJ/kg 125 kg/s Boiler Heat Transfer Steam Rate Condenser Heat Transfer Cycle Thermal Efficiency Power Rating (kW)arrow_forward1. (a) Hot oil at a flow rate of 5.5 kg/s (average cp = 1.92 kJ/kgK) enters an existing counter-flow exchanger at 435 K and is cooled by water entering at 325 K (under pressure) and flowing at a rate of 7.2 kg/s and the water exit temperature is 350 K. The overall heat transfer coefficient based on the outside area is 685 W/m²K (Average specific heat of water is 4.187 kJ/kgK). (i) Calculate the exit oil temperature. (ii) Calculate the heat transfer area. (b) The fluid in (a) enters an existing co-current-flow exchanger at the same conditions. (i) Calculate the heat transfer area. (ii) Explain the performance of both heat exchangers.arrow_forwardWater vapor expands at a turbine at a speed of 1350 kg / s, the inlet conditions are 8MPA and 400C, the outlet conditions are 500KPa and 250C, the turbine does 200kW work. Neglect changes in kinetic and potential energy. a) Write and simplify the equation that applies to this system. b) What are the specific enthalpies of the input and output current? c) What is the heat transfer in Kw? d) What is the specific volume and volumetric flow at the inlet? e) What is the specific volume and the volumetric flow at the outletarrow_forward

- Water is to be cooled from 110°F to 85°F in a packed countercurrent water- cooling tower using entering air at 85°F with a wet bulb temperature of 75°F. The water flow is 2000 lbm/h. ft2 and the air flow is 1400 lbm air/h.ft2. The overall mass-transfer coefficient is KGa = 6.90 lb mol/h.ft3.atm. Calculate the tower height needed if air flow of 1400 lbm air/h.ft2 is used.arrow_forward1. Consider a 1000 MW power plant located in a rural area with 15 ton/day SO2 emissions from a 100 m high stack. The velocity and temperature of the stack gases lead to an effective stack height of 50 m above the physical stack. Estimate the ground level concentration as a function of distance downwind under the following conditions. The emissions are into a clear daytime atmosphere with wind (at 10 m) of 5 m/s. b. The emissions are into a clear nighttime atmosphere with wind (at 10 m) of 2 m/s. The conditions of a. except there is a strong elevated inversion at an altitude of 200 m. a. С.arrow_forwardThe liquid food is flowed through an uninsulated pipe at 90 ° C. The product flow rate is 0.25 kg / s and has a density of 1000 kg / m³, a specific heat of 4 kJ / (kg K), a viscosity of 8 x 10-6 Pa s, and a thermal conductivity of 0.55 W / (m) K). Assume that the change in viscosity is negligible. The internal diameter of the pipe is 25 mm with a thickness of 3 mm made of stainless steel (k = 15 W / [m ° C]). The outside temperature is 15 ° C. If the outer convective heat transfer coefficient is 18 W / (m² K), calculate the heat loss at steady state per meter pipe length. a. Find the convection coefficient in the pipe = AnswerW / m² ° C. b. Calculate heat loss per meter pipe length = Answerwatt.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The