Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

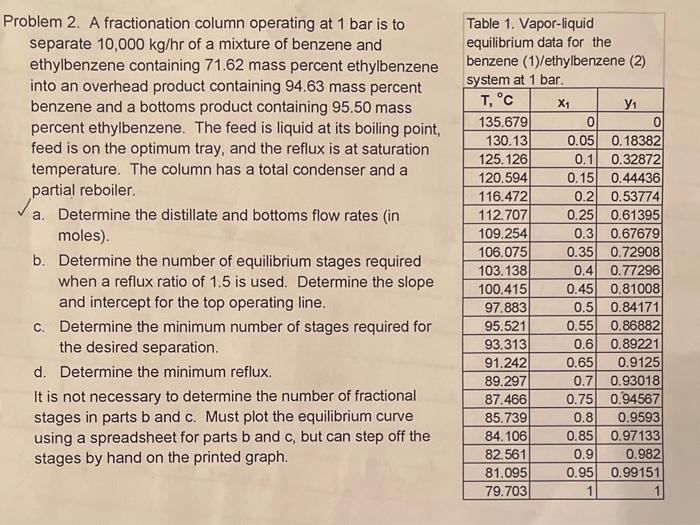

Transcribed Image Text:Problem 2. A fractionation column operating at 1 bar is to

separate 10,000 kg/hr of a mixture of benzene and

ethylbenzene containing 71.62 mass percent ethylbenzene

into an overhead product containing 94.63 mass percent

benzene and a bottoms product containing 95.50 mass

percent ethylbenzene. The feed is liquid at its boiling point,

feed is on the optimum tray, and the reflux is at saturation

temperature. The column has a total condenser and a

partial reboiler.

a. Determine the distillate and bottoms flow rates (in

moles).

b. Determine the number of equilibrium stages required

when a reflux ratio of 1.5 is used. Determine the slope

and intercept for the top operating line.

c. Determine the minimum number of stages required for

the desired separation.

d. Determine the minimum reflux.

It is not necessary to determine the number of fractional

stages in parts b and c. Must plot the equilibrium curve

using a spreadsheet for parts b and c, but can step off the

stages by hand on the printed graph.

Table 1. Vapor-liquid

equilibrium data for the

benzene (1)/ethylbenzene (2)

system at 1 bar.

T, °C

X₁

135.679

130.13

125.126

120.594

116.472

112.707

109.254

106.075

103.138

100.415

97.883

95.521

93.313

91.242

89.297

87.466

85.739

84.106

82.561

81.095

79.703

У1

0

0

0.05 0.18382

0.1

0.32872

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.9

0.95

1

0.44436

0.53774

0.61395

0.67679

0.72908

0.77296

0.81008

0.84171

0.55

0.86882

0.6 0.89221

0.65

0.9125

0.7 0.93018

0.75 0.94567

0.8

0.9593

0.85

0.97133

0.982

0.99151

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 6 steps with 5 images

Knowledge Booster

Similar questions

- 5. The following table shows data from a flow study of a PS melt at 210°C in a capillary rheometer. a. Make a plot of log shear stress versus log shear rate. b. Calculate the value of the viscosity at 1 and 135 s', respectively. Shear Stress ,(10° dyn/cm') Shear Rate, 3.5 1.0 12.0 5.0 20.0 12.2 33.0 25.0 40.0 52.5 60.0 135.0 69.8 400.0arrow_forwardDescribe the formation of hydrocarbon from organic matter.Explain the 'flow separation phenomena' for flow over a cylinder in cross flow. Can flow separation occur over a flat platearrow_forward

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The