Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

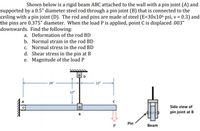

Transcribed Image Text:Shown below is a rigid beam ABC attached to the wall with a pin joint (A) and

supported by a 0.5" diameter steel rod through a pin joint (B) that is connected to the

ceiling with a pin joint (D). The rod and pins are made of steel (E=30x106 psi, v = 0.3) and

the pins are 0.375" diameter. When the load P is applied, point C is displaced .003"

downwards. Find the following:

a. Deformation of the rod BD

b. Normal strain in the rod BD

c. Normal stress in the rod BD

d. Shear stress in the pin at B

e. Magnitude of the load P

24"

12"

12"

Side view of

pin joint at B

B

Pin

Beam

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Three metal rods are firmly attached to the walls and the middle rigid plate. Rod AB is made from stainless steel and rods CD and EF are made from 2014-T6 aluminum. If a balanced load is applied to the rigid plate, determine what the stresses are in the rods. Follow the sign convention that tensile stress is positive and compressive stress is negative. The parameter values are listed in the table above the figure. parameter value units L. 450 mm L2 300 mm d₁ 40 mm d2 30 mm P 40 KN L1 d₁ P B CC 030 BY NO SA 2021 Cathy Zupke P L2 D U MPa MPa The stress in AB σAB= The stress in CD and EF: σCD = σEF= E Farrow_forwardThe supporting wheel on a scaffold is held in place on the leg using a 4-mm-diameter pin as shown. (Figure 1) Figure 1 of 1 > Part A If the wheel is subjected to a normal force of P = 3.3 kN, determine the average shear stress developed in the pin. Neglect friction between the inner scaffold puller leg and the tube used on the wheel. Express your answer to three significant figures and include the appropriate units. Tavg= Submit Provide Feedback Value A Request Answer C Units ? Next >arrow_forward1. A solid square rod is cantilevered at one end. The rod is 0.8 m long and supports a completely reversing transverse load at the other end of 50 kN. The material is AISI 1060 hot-rolled steel (?? =370 MPa,?? =680 MPa ). Use a design factor of 2 and determine the dimensions of the square cross section for the following cases. Neglect any stress concentration. a. The rod must support this load for 100 cycles. b. The rod must support this load for 104 cycles. c. The rod must have infinite life.arrow_forward

- The two angle bars are used to support a tensile load "T". Assume the tensile load to be equally resisted by each angle. 400 mm x 20 mm THK Gusset Plate The steel used is L 6 x 6 x 1. Properties: A = 7096.76 mm? y = 47.244 mm Fy = 248 MPa Fu = 400 MPa b = 152.4 mm b. t = 25.4 mm x = 47.244 mm Effective hole diameter = 25 mm y Use case 2 for shear lag factor. Use NSCP 2015 code. 1. Determine the maximum allowable load that can be carried by the two L6 x 6 x1 based on yielding of the gross section--- 2. Determine the maximum factored load that can be carried by two L6 x 6 x 1, based on the fracture of the effective net area.---- 3. Determine the maximum allowable tensile load that can be carried.------ 4. Determine the maximum factored tensile load that can be carried-- boarrow_forward10000 lb is applied at G, pin C can have 5000 max horizontal load and 6000 vertical load, determine max angle of bedarrow_forwardA long, slender structural aluminum [E = 69 GPa] flanged shape is used as a l = 9.2-m-long column. The column is supported in the x direction at base A and pinned at ends A and C against translation in the y and z directions. Lateral support is provided to the column so that deflection in the x-z plane is restrained at mid-height B; however, the column is free to deflect in the x-y plane at B. Assume that b; = 102 mm, d = 122 mm, t; = 8 mm, and tw = 6 mm. Determine the maximum compressive load P the column can support if a factor of safety of 2.9 is required. In your analysis, consider the possibility that buckling could occur about either the strong axis (i.e., the z axis) or the weak axis (i.e., the y axis) of the aluminum column. bf C L Lateral B bracing L 2 Aarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY