Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

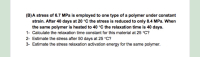

( B ) A stress of 6.7 MPa is employed to one type of a polymer under constant strain . After 40 days at 20 ° C the stress is reduced to only 8.4 MPa . When the same polymer is heated to 40 ° C the relaxation time is 40 days . 1- Calculate the relaxation time constant for this material at 25 ° C ? 2- Estimate the stress after 50 days at 25 ° C ? 3- Estimate the stress relaxation activation energy for the same polymer .

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 1) Assuming that the moduli and volume fractions of fiber and matrix materials are known, obtain the rule of mixtures in order to calculate the longitudinal Young's (elasticity) modulus of a unidirectional lamina by use of iso-strain assumptionarrow_forwardAt room temperature, most polymers have similar fracture toughness compared to metals. O True Falsearrow_forwardFor a glass/epoxy lamina with a 70% fiber volume fraction using the properties in the tables provided below (a) Find the ultimate tensile strength. (b) Find the minimum and critical fiber volume fractions related to (a). (c) Find the compressive strength when the matrix undergoes extension mode and when the matrix undergoes shear mode, which one controls the compressive failure? Property Axial modulus Transverse modulus Axial Poisson's ratio Transverse Poisson's ratio Shear modulus Axial tensile strength Axial compressive strength Transverse tensile strength Transverse compressive strength Shear strength Epoxy Glass Units 3.4 85 GPa 3.4 85 GPa 0.3 0.20 0.3 0.20 1.308 35.42 GPa 72 1550 MPa 102 1550 MPa 72 1550 MPa 102 1550 MPa 34 35 MPaarrow_forward

- State the critical difference in the processing behavior of thermoplastics vs. thermosets.arrow_forwardFrom the attached image. Annotate and explain the phases of the polymer stress-strain curve.arrow_forwardCalculate the composite elastic modulus for polyester reinforced with 60% volume fraction of carbon fibers under isostrain longitudinal conditions. Modulus of elasticity of polyester is 2900 MPa and for carbon fiber is 175,000 MPa.arrow_forward

- Explain the relationship between STRUCTURE/ PROPERTIES/ PROCESSING/ PERFORMANCE of a polymer which is a drawn fiber thermoplastic. You should have at least a sentence for each of these.arrow_forwardDescribe, giving an example, how annealing affects the dynamic-mechanical thermal (DMT) properties of crystalline thermoplastics.arrow_forwardA discontinuous fibre reinforced composite consists of 20mm long carbon fibres in a polymer matrix. The volume fraction of the composite is 0.5, interfacial shear strength 5MPa and the critical fibre length 2.5mm. The fibre modulus is 250GPa and strain to failure 1.5%. The matrix modulus is 3.5GPa and failure strain 10%. Calculate the tensile strength of the composite in the fibre direction. Answer: 3564arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY