A process considered to be in control measures an ingredient in ounces. Roberto Baggio, a quality inspector took 20 samples, each with 8 observations as follows: thats in the pictuer after that using this information, obtain three-sigma (i.e., z=3) control limits for a mean control chart and control limits for a range chart, respectively. It is known from previous experience that the standard deviation of the process is 0.693. First: perform all actions and calculations needed to answer the question. All equations/calculations needed to be fully written STEP by STEP. No short calculations or direct answers/results will be accepted. This applies to the calculations for both types of control limits (mean and range). Second: Explain the process followed to identify each type of control limit and any observations made in the problem-solving process.

A process considered to be in control measures an ingredient in ounces.

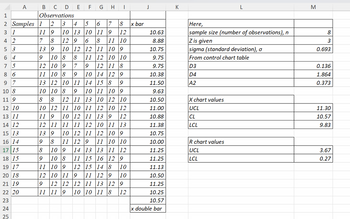

Roberto Baggio, a quality inspector took 20 samples, each with 8 observations as follows:

thats in the pictuer

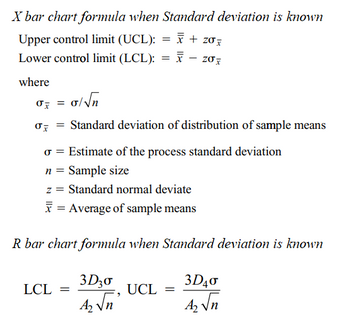

after that using this information, obtain three-sigma (i.e., z=3) control limits for a mean control chart and control limits for a range chart, respectively. It is known from previous experience that the standard deviation of the process is 0.693.

First: perform all actions and calculations needed to answer the question.

All equations/calculations needed to be fully written STEP by STEP. No short calculations or direct answers/results will be accepted.

This applies to the calculations for both types of control limits (mean and range).

Second: Explain the process followed to identify each type of control limit and any observations made in the problem-solving process.

thank you very much

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 10 images

thank you for your answer i found something similar on bertleby but the working out is different and the answers are slighilty different too i am not sure which one to use:

this is the answer that i found:

this are his answers but in the picture is working out

X chart values

UCL 11.30

CL 10.57

LCL 9.83

R chart values

UCL 3.67

LCL 0.27