Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

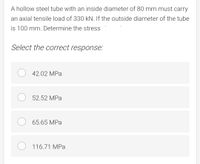

Transcribed Image Text:A hollow steel tube with an inside diameter of 80 mm must carry

an axial tensile load of 330 kN. If the outside diameter of the tube

is 100 mm. Determine the stress

Select the correct response:

42.02 MPa

52.52 MPa

65.65 MPa

116.71 MPa

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- A circular aluminum alloy [E = 70 GPa; a = 22.5 x 10-6/°C; v = 0.33] pipe has an outside diameter of 220 mm, a wall thickness of 15 mm, and a length of 4.0 m. The pipe supports a compressive load of 650 kN. After the temperature of the pipe drops 41°C, determine: (a) the axial deformation of the pipe. (b) the change in diameter of the pipe. Answer: (a) ō = i mm AD = i mmarrow_forwardA 2 m long alloy bar of 1500 mm? cross-section area hangs vertically and has a collar securely fixed at its lower end. Find the stress induced in the bar, when a weight of 1 kN falls from a height of 100 mm on the collar. [E = 120 GPa]arrow_forwardA circular aluminum alloy [E = 70 GPa; a = 22.5 x 10-6/°C; v = 0.33] pipe has an outside diameter of 215 mm, a wall thickness of 12 mm, and a length of 5.4 m. The pipe supports a compressive load of 600 kN. After the temperature of the pipe drops 40°C, determine: (a) the axial deformation of the pipe. (b) the change in diameter of the pipe. Answer:arrow_forward

- For a given steel cube section subjected to three dimensional state of principal stress. 75N/mm² ŠI 150 N/mm 30 N/mm² Consider yield stress = 250 N/mm², and µ = 0.3 The value of factor of safety according to maximum strain energy theory. -Xarrow_forwardThe bronze bar 3 m long with a cross-sectional area of 350 mm2 is placed between two rigid walls. At a temperature of -20°C, there is a gap A = 2.2 mm, as shown in the figure. Find the temperature at which the compressive stress in the bar will be 30 MPa. Use a = 18.0x 10-6 / °C and E = 80 GPa. 3 m-arrow_forward(c) A piece of material is subjected to tensile stress of 70 N/mm² in one direction and a compressive stress of 50 N/mm² in a direction at right angles to the previous one. Find fully the stresses on a plane the normal of which makes an angle of 40 degree with the 70 N/mm² stress.arrow_forward

- As shown, an aluminium alloy construction BCD with a circular cross section is fixed at end B and affected by a force of 150 N at the free end D. The diameter of the cross-section a-a is 20 mm. The yield strength of the material is 80 MPa: a) Determine the stresses at point A of the a-a cross-section. As indicated in the picture, draw the stress element in Cartesian coordinates and specify the stress values.(b) Calculate the factor of safety, n for Tresca, and the von Mises yield criterion to see if the structure would yield based on the stresses at point A.(c) In the major stress area, draw the yield loci of both criteria and indicate the operational stress state & why is the Rankine failure criterion inappropriate for aluminium alloys?arrow_forward3. An ASTM A36 structural steel beam 5.00 m long is placed between two rigid supports. When the temperature is 20°C, there is no stress in the bar. Compute the stress developed in the beam if the temperature rises to 45°C. Assume that the proportional limit is 235 MPa. a = 11.7 x 10-6 1/C° E = 207 GPaarrow_forwardPlease solve this question in hand wirting step by step.arrow_forward

- A 25-mm-diameter aluminum rod, 4 m long, is subjected to an axial tensile load of 50 kN Assume a proportional limit of 200 MPa and E = 70 GPa. Compute: a) Stress b) Strain c) Total elongationarrow_forwardAn aluminum rod is rigidly attached between a steel rod and a bronze rod as shown below. Axial loads are applied at the positions indicated. Find the maximum value of P in Newton that will not exceed a stress in steel of 150 MPa, in aluminum of 87 MPa, or in bronze of 97 MPa.arrow_forwardNormal stress is calculated dividing the reaction by the cross-sectional area. Is this approach valid for any point of a structural member? Why or why not? To answer this question, consider the loading point, cross- sectional shape, etc.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning