Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

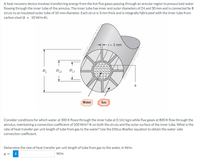

Transcribed Image Text:A heat recovery device involves transferring energy from the hot flue gases passing through an annular region to pressurized water

flowing through the inner tube of the annulus. The inner tube has inner and outer diameters of 24 and 30 mm and is connected by 8

struts to an insulated outer tube of 50-mm diameter. Each strut is 3 mm thick and is integrally fabricated with the inner tube from

carbon steel (k = 50 W/m-K).

+ t = 3 mm

1=3

↑

Do

D₁,2

D₁,1

+

h

Water

Gas

Consider conditions for which water at 300 K flows through the inner tube at 0.161 kg/s while flue gases at 800 K flow through the

annulus, maintaining a convection coefficient of 100 W/m².K on both the struts and the outer surface of the inner tube. What is the

rate of heat transfer per unit length of tube from gas to the water? Use the Dittus-Boelter equation to obtain the water-side

convection coefficient.

Determine the rate of heat transfer per unit length of tube from gas to the water, in W/m.

W/m

q= i

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A shell-and-tube heat exchanger is used to cool compressed liquid methanol from 176 °F to 104 °F. The methanol flows on the shell side of the exchanger. The coolant is water that rises in temperature from 50 °F to 86 °F and flows within the tubes at a rate of 68.9 kg s1. Finding the appropriate thermophysical data and applying the proper equations, you are required to do the following: (a) Calculate i) methanol mass flow rate in the exchanger, ii) methanol volumetric flowrate at the inlet of the exchanger. (b) i) For the counter-current flow of the fluids calculate the log temperature difference, ii) explain the purpose of calculating this difference, iii) explain, quantitatively, why is the counter-current flow in heat exchangers preferred to co-current flow. meanarrow_forwardThe condenser of a large thermal power plant is a body-tube type heat exchanger consisting of a single body and 30000 pipes with two passes each. The pipes are thin-walled with an inner diameter of 25 mm, and steam condenses on the outer surfaces of the pipes with a convection coefficient of 11000 W / m2.K. The heat transfer required by the heat exchanger is 2000 MW, and it is provided by the flow of water through the pipes at a flow rate of 30000 kg / h. Water enters at 20 ° C, steam condenses at 50 ° C. Calculate the temperature of the cooling water leaving the condenser? Determine the required pipe length per pass? The properties of water at Tort = 300 K; Cp = 4180 j / kgK, μ = 855 × 10--6 Ns / m2, k = 0.613 W / mK, Pr = 5.83.arrow_forwardA heat recovery device involves transferring energy from the hot flue gases passing through an annular region to pressurized water flowing through the inner tube of the annulus. The inner tube has inner and outer diameters of 24 and 30 mm and is connected by 8 struts to an insulated outer tube of 45-mm diameter. Each strut is 3 mm thick and is integrally fabricated with the inner tube from carbon steel (k = 50 W/m-K). D₂ D₁,2 Dil ↓ Water 1=3 mm Gas h Consider conditions for which water at 300 K flows through the inner tube at 0.161 kg/s while flue gases at 800 K flow through the annulus, maintaining a convection coefficient of 100 W/m².K on both the struts and the outer surface of the inner tube. What is the rate of heat transfer per unit length of tube from gas to the water? Use the Dittus-Boelter equation to obtain the water-side convection coefficient. Determine the rate of heat transfer per unit length of tube from gas to the water, in W/m. 9 = i W/marrow_forward

- A single-pass, cross-flow heat exchanger uses hot exhaust gases (mixed) to heat water (unmixed) from 30 to 70 °C at a rate of 3 kg/s. The exhaust gases, having thermophysical properties similar to air, enter and exit the exchanger at 200 and 100 °C, respectively. If the overall heat transfer coefficient is 200 W/m2 ·K, estimate the required surface area. Hint : from 30 to 70 °C at a rate of 3 kg/s.arrow_forwardA parallel flow heat exchanger is to be designed to heat 4535 kg/hr of water from 21°C to 43°C with the steam condensing at 121°C on the outside of the tubes. Tubes of 2.54 cm outside diameter and 2.286 cm inside diameter, 2.44m long, are available for use. Assuming that the average steam-side coefficient is 5675 W/m²-°C, and the thermal conductivity of the tube metal is 110.73 W/m²-°C, calculate the required number of tube per pass. Assume that the velocity of the water entering each tube is equal to 0.457 m/sec. a. 7 c. 9 b. 8 d. 10arrow_forwardConsider the flow of motor oil (cp=2048 J/kg K) through a copper tube ofthin wall at a rate of 0.3 kg/s. The oil enters the copper tubes at atemperature of 80°C that is cooled by means of water that enters at 20°C. Temperatureoutlet of the oil cannot be higher than 40°C. The convective coefficient ofheat transfer from the oil side is 750W/m2 K and from the water side 350W/m2 K. IfThe outlet temperature of the water is measured at 32°C and a heat exchanger is considered.double tube in parallel. Determine: a) Mass flow rate of the water. b) The difference of log mean temperatures. c) the area of the heat exchanger.arrow_forward

- It is proposed to cool oil in a counter-current, concentric tube heatexchanger composed of a thin-walled inner tube of 0.02 m diametercarrying oil and thin-walled, perfectly insulated outer tube of 0.05 mdiameter carrying water. The oil flow rate is 50.0 kg min-1 and it has to becooled from 90°C to 40°C using 60 kg min-1 water at 20°C. Determine the length required for the heat exchanger. Comment onthe practicality of this length.arrow_forwardA long, thin-walled double-pipe heat exchanger with tube and shell diameters of 0.01 m and 0.025 m, respectively, is used to condense refrigerant-134a with water at 20°C. The refrigerant flows through the tube, with a convection heat transfer coefficient of hi= 4100 W/m² °C. Water flows through the shell at a rate of 0.3 kg/s. The thermal resistance of the inner tube is negligible since the tube material is highly conductive and its thickness is negligible. Both the water and refrigerant-134a flows are fully developed. Properties of the water and refrigerant-134a are constant. Water properties: p = 998 kg/m³, v=u/p-1.004x 10-6 m²/s, k = 0.598 W/m. °C, Pr = 7.01 Cold water D Doarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY