Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

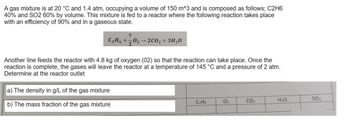

Transcribed Image Text:A gas mixture is at 20 °C and 1.4 atm, occupying a volume of 150 m^3 and is composed as follows; C2H6

40% and SO2 60% by volume. This mixture is fed to a reactor where the following reaction takes place

with an efficiency of 90% and in a gaseous state.

7

C₂H6+02 → 2C0₂ + 3H₂0

2

Another line feeds the reactor with 4.8 kg of oxygen (02) so that the reaction can take place. Once the

reaction is complete, the gases will leave the reactor at a temperature of 145 °C and a pressure of 2 atm.

Determine at the reactor outlet

a) The density in g/L of the gas mixture

b) The mass fraction of the gas mixture

C₂H6

0₂

CO₂

H₂O

SO₂

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 20 images

Knowledge Booster

Similar questions

- mixture. 2. Gas A is reacted with gas B in a batch reactor: A + 3B → 3C Stoichiometric ratio of A and B are mixed in the fixed volume reactor at 20°C and a total absolute pressure of 2 atm. The mixture starts to react and the reaction goes to completion at 2.5 atm. What is the final temperature of the reaction mixture, assuming ideal gas behaviour?arrow_forwardAbsolute (100%) ethanol is produced from 95% ethanol and 5% water using the Keyes distillation process. Another component, benzene, is added to lower the instability of the alcohol. With these conditions, the product from the top of the distiller is a constant-boiling mixture of 18.5% ethanol, 7.4% H₂O, and 74.1% benzene, as shown here: 95% ethanol 5% water Benzene Distillation tower P(absolute ethanol) = 0.785 g/cm³ P(benzene) = 0.872 g/cm³ 74.1% benzene 18.5% ethanol 7.4% water 100% ethanol Calculate the volume of benzene that should be fed to the still to produce 250 L of absolute ethanol, using this data:arrow_forwardA fuel with a molar composition of 75% CH4 and 25% C2H6 enters a burner with an excess of 80% air and is fully burned there. The temperature of the fuel and air entering the burner is 298 K; Since the temperature of the combustion products coming out of the burner is 550 K, calculate the transferred heat as (kJ / kmol fuel). (Cp / R = A + BT)arrow_forward

- An equimolar mixture of nitrogen and acetylene enters a steady-flow reactor at 25°C and atmospheric pressure. The only reaction occurring is: N2(g) + C2H2 → 2HCN(g)N2(g) + C2H2 → 2HCN(g) The product gases leave the reactor at 600°C and contain 24.2 mol-% HCN. How much heat is supplied to the reactor per mole of product gas? (Use the tables for standard enthalpies and gibbs energies of formation and the heat capacities of gases in the ideal gas state.)arrow_forwardAcetylene (C2H2) may be formed from methane (CH4) by pyrolyzing-decomposing at high temperature according to the reaction: 2CH4 (g) → C2H2 (g) + 3H2 (g) In a commercial reactor system, the methane is supplied as a liquid at 25°C to a heater where it is heated and vapourised leaving as a vapour at 650°C. The vapour then passes to the catalytic reactor in which a conversion of 40% is achieved. It may be assumed that there are no other reactions, that operation is at a pressure of one atmosphere and that the stream leaving the reactor is all in the vapour state. With a complete block diagram of the process, determine the heat transfer rate (kW) required to the reactor if it is operated isothermally. Evaluate on the value of the heat transfer rate obtained from your calculation. Component State Δ?? °(kJ/mol) Cp (kJ/mol·K) Methane Liquid ----------- ---------- Gas -74.85 0.34 Acetylene Liquid ---------- ---------- Gas 226.75 0.42 Hydrogen Gas ---------- 0.059 The Cp…arrow_forwardQ2. Consider a fuel which is an equimolar mixture (1 mole each) of propane (C3Hs) and methane (CH4). (a) Write the complete stoichiometric combustion reaction for this fuel with air (b) Determine the stoichiometric A/F ratio of this fuel (C) Estimate the maximum flame temperature using average specific heat cp at 1200 K. Assume the boiler using this fuel operates at 1 atm and the reactants enter at 298 K. AH(C3H8) -103,847 kJ/kmol. AHCHA)-74,831 kJ/kmol AH (H20) =-241,847 kJ/kmol, AH'r(co2) - 393,546 kJ/kmol, CP120-43.87 kJ/kmol.K Cpco2 = 56.20 kJ/kmol.K. Cps2 = 33.71 kJ/kmol.Karrow_forward

- Problem 3. Acetylene is produced from methane in the reaction C2H2 (g) 3H2 (g) 2CH4 (g) An undesired side reaction is the decomposition of acetylene: 2C(s) + H2(g) C2H2(g) Methane is fed to the reactor at 1500°C at a rate of 10 mol/s. Heat is transferred to the reactor at a rate of 975 kW. The product temperature is 1500°C and the fractional conversion of methane is 0.600. A flowchart of the process and an enthalpy table are shown below 975 kW Product at 1500 °C Feed at 1500°C REACTOR mol CH/s) i(mol CH/s) ig(mol H/s) ig(mol C/s) 10.0 mol CH/s References: C(s), H2(g), at 25°C, 1 atm Hin (kJ/mol Нou (kJ/mol йin (mol/s nout (mol/s) Substance й CH4 10.0 41.65 На |СНа йz Нз На йз На C a) Using the heat capacities and enthalpies given below, determine the product component flow rates and the yield of acetylene (mol C2H2 produced/mol CH4 consumed) Hints: . Consider all available equations, and ii. Atomic balances are more than a midterm gimmick Cp (methane) 0.079 kJ/mol-C Cp (acetylene) =…arrow_forwardNormal heptane is dehydrocyclicized to toluene and hydrogen in a continuous vapor-phasereaction:C7H16 → C6H5CH3 + 4 H2Pure heptane at 400°C is fed to the reactor at a rate of 100 mol/s. The reactor operatesisothermally at 400°C and the reaction goes to completion. Data: The average heat capacity of nheptane between 25°C and 400°C is 0.2427 kJ/(mol°C). Calculate the required heat transfer to orfrom the reactor in kJ/s. What is the heat of the heptane dehydrocyclization reaction at 400°C and1 atm?arrow_forwardAn important process for the production of acrylonitrile (C3H3N) (US production is greater than 10^9 lb) is given by the following reaction: 2C3H4(g) + 2NH3(g) +3O2(g) --> 2C3H3N(g) + 6H2O(g) A 150.-L reactor is charged to the following partial pressures at 25°C: P( C3H4) = 0.500 MPa P (NH3) = 0.800 MPa P (O2) = 1.500 MPa What mass of acrylonitrile can be produced from this mixture (MPa = 10^6 Pa)? Find the limiting reagent, theoretical yield of acrylonitrile in kilograms. Assuming the reaction above can achieve completion (actually a wrong assumption), what should be the mass of the other two excess reactants after the reaction in kilogramsarrow_forward

- 8.29 Show complete solution and diagramarrow_forwardIsopropanol, with 13 wt% water, can be dehydrated to obtain almost pure isopropanol at a 90% recovery by azeotropic distillation with benzene. When condensed, the overhead vapor from the col- umn forms two immiscible liquid phases. Use Table 2.4 with data in Perry's Handbook and the data below to compute the heat-transfer rate in Btu/h and kJ/h for the condenser. Water-Rich Organic-Rich Overhead Phase Phase Phase Vapor Liquid Liquid Temperature, °C 76 40 40 Pressure, bar 1.4 1.4 1.4 Flow rate, kg/h: Isopropanol 6,800 5,870 930 Water 2,350 1,790 560 Benzene 24,600 30 24,570arrow_forwardFind the difference between the heat of reaction at constant pressure and at constant volume for the following reaction at 25°C (assuming that it could take place)arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The