Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

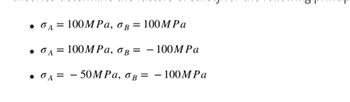

A ductile hot-rolled steel bar has a minimum yield strength in tension and compression of 350 MPa. Using the distortion-energy and maximum-shear-stress theories determine the factors of safety for the following principal stresses:

Transcribed Image Text:•

•

•

A = 100MPa, og = 100MPa

A = 100MPa, OB = -100MPa

A = -50MPa, B = -100MPa

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- topic: rigid bodiesarrow_forwardLong, square rod in a long cylinder. Also, what is F22? F12 = F21 = || F22 = i w=D/5 A₁ -A₂ tarrow_forwardDifferent expert. Please help. Written on paper not typed on computer please. Need help on all questions. Please include all units, steps to the problem and information such as its direction or if it is in compression or tension. Thx.arrow_forward

- Solve the distributed load problem attached using both the calculus and the composite areas methods.arrow_forward1MPA = 1N/mm? Select one: True Falsearrow_forward2. A element was made of a material with the material parameters of ob-650MPa, os 600MPa, o-1-360MPa, 0-600MPa. The stresses on the most dangerous section are max 250MPa, min-100MPa. The element work under the situation -C(constant). K-1.5. Please: 1) Draw out the constant life curves of material and shaft. 2) Mark out the working point and ultimate point figure. 3) Calculate the safety factor by graphical method.arrow_forward

- Task 2 Q1. A tensile testing machine operates using two lead screws. Both lead screws have a square thread profile and can withstand the maximum load of 16 tonnes & torque of 150 KNm. The pitch width p = l = 4 mm. what is the efficiency of the square thread?arrow_forwardThe critical stress element of a machine part is provided below. The engineer is considering two materials and the factor of safety is a concern. a. AISI 1025 CD steel (Sy 415 MPa, Sut = 505 MPa) b. ASTM Class 30 Gray Cast Iron (Sut = 214 MPa and Suc = 751 MPa) 70 MPa 80 MPa For a Non-Conservative Design, which of the two materials do you consider safe and why? 60 MPaarrow_forwardWhich one of the following, in some form or another, causes all other choices? Shear stress Force Normal Stress Bearing Stressarrow_forward

- Required Information NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. A Howe roof truss is shown. Take P₁= P₂= P3 = 600 lb. P2 300 b P1 BY CI P3 E SASHSA→→SA- The force in member AB (FAB) is The force in member AC (FAC) is The force in member BC (FBC) is The force in member CE (FCE) is The force in member BD (FBD) is The force in member BE (FB) is The force in member DF (FDA) is The force in member DE (FDE) is The force in member EF (FEA) is The force in member EG (FEG) is The force in member FG (FFG) is The force in member FH (FFH) is The force in member GH (FGH) is 300 lb 6 ft G H 6 ft Determine the force in each member of the Howe roof truss shown. State whether each member is in tension (7) or compression (C). lb (Click to select) V lb (Click to select) lb (Click to select) lb (Click to select) lb (Click to select) lb (Click to select) lb (Click to select) lb (Click to select) lb (Click to select) V lb (Click to select) lb…arrow_forwardthe correct answer is 3arrow_forwardf in a tensile loading application, the factor of safety for one member is set as FS = 2.2 based on the material's tensile (failure) strength as = 614 MPa, then the load member's allowable stress in this application will be: = _______ MPa. Calculate your answer to 1 decimal place.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY