Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

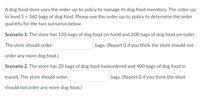

Transcribed Image Text:A dog food store uses the order-up-to policy to manage its dog food inventory. The order-up-

to level S = 360 bags of dog food. Please use the order-up-to policy to determine the order

quantity for the two scenarios below.

Scenario 1. The store has 120 bags of dog food on-hand and 200 bags of dog food on-order.

The store should order

bags. (Report 0 if you think the store should not

order any more dog food.)

Scenario 2. The store has 20 bags of dog food backordered and 400 bags of dog food in

transit. The store should order

bags. (Report 0 if you think the store

should not order any more dog food.)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A demand driven model will likely lead to higher inventory levels due to safety stock. True Falsearrow_forwardIf D = 8,500 per month, S = $42 per order, and H= $2.50 per unit per month, a) What is the economic order quantity? The EOQ is b) How does your answer change if the holding cost doubles? The EOQ is units (round your response to the nearest whole number). The EOQ is units (round your response to the nearest whole number). c) What if the holding cost drops in half? units (round your response to the nearest whole number).arrow_forward16 Brooke Army Medical Center dispenses 390,000 bottles of brand name pharmaceutical annually. The optimal safety stock (which is on hand initially) is 1,000 bottles. Each bottle costs the center $10, inventory carrying costs are 30%, and the cost of placing an order with its supplier is $175. I What is the economic order quantity? Format is x,xxx (number only) What is the maximum inventory for this medication? Format is x,xxx How often must the center order (in days)? Format is xx days or x days How many orders of this pharmaceutical will need to be placed each year? Format is x or xx (number only)arrow_forward

- Ray's Satellite Emporium wishes to determine the best order size for its best-selling satellite dish (model TS111). Ray has estimated the annual demand for this model at 1,750 units. His cost to carry one unit is $95 per year per unit, and he has estimated that each order costs $36 to place. Using the EOQ model, how many should Ray order each time? (Round your answer to the nearest whole number.) Optimal order quantity unitsarrow_forwardRay wishes to determine the optimal order quantity for its best-selling bike in his bike store. Ray pays the supplier a wholesale price of $118 each for this bike. Ray has estimated the average daily demand for this bike is 23 units. The store opens 304 days a year. The cost to carry one bike in the store for a whole year is 8% of the unit bike cost. Ray has estimated that, on average, the order processing cost, i.e., ordering cost, with the bike supplier each time is $152, and it roughly takes 20 working days to receive the order from the supplier. Ray wishes to avoid the stock-out situation with a probability of 95%, and this requires Ray to carry a safety stock of 30 bikes in the store. What is the optimal order quantity (EOQ value) that Ray should order each time from the bike supplier to minimize his long-run inventory cost?arrow_forwardWith a normal demand and normal lead-time, increasing the order lead-time results in which of the following? Lower expected costs. Higher service levels. Higher stockout probability. All of the above.arrow_forward

- The daily demand for printer paper at the School of Business is approximately normal with a mean of 15.2 boxes and a standard deviation of 1.6 per day. The Administrative Assistant reviews the inventory every 30 days, and the lead time is 5 days. The division set a policy of satisfying 96% of the demand for paper. If there are 125 boxes of printer paper in inventory at the beginning of this review period, how many boxes of printer paper should be ordered? What is the variance of demand during the review period plus the lead-time period? What is the standard deviation of demand during the review period plus the lead-time period? A. Variance = 76.80 Standard deviation = 8.76 B. Variance = 89.60 Standard deviation = 9.47 C. Variance = 9.47 Standard deviation = 89.60 D. Variance = 12.8 Standard deviation = 3.58arrow_forwardABC analysis is based on the presumption that carefully controlling all items is necessary to produce important inventory savings. A True B Falsearrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.