Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

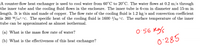

Transcribed Image Text:A counter-flow heat exchanger is used to cool water from 60°C to 20°C. The water flows at 0.2 m/s through

the inner tube and the cooling fluid flows in the enclosure. The inner tube is 6-cm in diameter and 15-m in

length. It is thin and made of copper. The flow rate of the cooling fluid is 1.2 kg/s and convection coefficient

is 360 W/m².°C. The specific heat of the cooling fluid is 1600 J/kg. °C. The surface temperature of the inner

tube can be approximated as almost isothermal.

(a) What is the mass flow rate of water?

0.56 kg/s

(b) What is the effectiveness of this heat exchanger?

0.285

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A liquid food flows in the inner pipe (internal diameter-8 cm) of a double-pipe heat exchanger. The liquid food (p=1200 kg/m and C,-4 kJ/kgK) flows at 0.055 m/min and enters the heat exchanger at 6°C and exits at 38°C. In the annular section, water at 96°C enters the heat exchanger and flows countercurrently at an average flow rate of 1 kg/s (average Cp= 4.18 kJ/kgK). a) Sketch a graph showing the temperature profile of the heating water and quid food through the heat exchanger. Clearly label the two streams and draw arrows to indicate the flow directions of liquid food and water. i) ii) Calculate the mass flow rate (kg/s) of the liquid food. ii) Me sure the temperature (°C) of the exiting water stream. iv) Calculate the log-mean temperature difference for this system. Estimate the length (m) of this pipe heat exchanger that needs to be constructed in order to achieve an overall heat transfer coefficient of 2.5 W/m2K.arrow_forwardIn order to cool a mass flow rate of 25 Kg/h of air (cp = 1060 J/Kg oC) at 300 oC, it is passed through the tube side of a counter flow heat exchanger with a length of 2 m and 2.54 cm tube outer diameter. The cooling water, (cp = 4182 J/Kg oC and r = 1000 Kg/m3), enters the heat exchanger at a temperature of 30 oC with a volume flow rate of 0.3 Litre/min. If the overall heat transfer coefficient, U, is 5.83 W/m2 oC and the effectiveness of the heat exchanger 60 %, calculate the following: The heat transfer rate, The exit temperatures of both the water and the air, The surface area of the heat exchanger, The number of tubes used in the heat exchanger The capacity rate ratio.arrow_forwardA shell-and-tube heat exchanger with two-shell passes and 4-tube passes is used for cooling oil (cp = 2.0 kJ/kg·K) from 125°C to 55°C. The coolant is water, which enters the shell side at 25°C and leaves at 46°C. The overall heat transfer coefficient is 900 W/m2·K. For an oil flow rate of 10 kg/s, calculate the cooling water flow rate and the heat transfer area.arrow_forward

- Please explain with steps.arrow_forwardA heat exchanger is heating water on the tube side with steam condensing on the shell side. The water is entering at 45 0 F and exiting at 175 0 F. No instruments are available for measuring the tube side water flow but condensed steam from the shell side is being collected at a rate of 43 GPM. If the tube area of the exchanger is 350 Ft2 , and the overall heat transfer coefficient clean was 900 BTU/Hr.Ft2 F0, how much has the overall heat transfer coefficient changed, if at all? Note: Latent heat for water/steam at 212 0 F is 970 BTU per pound of water. A gallon of water weighs 8.34 lbs.arrow_forwardConsider a flow of water in a cylinder maintained at constant temperature of 1000 C, the diameter of the cylinder is 50 mm and the length of the tube is 6m. The inlet and the outlet temperature of the water is Ti = 150 C and T0 = 570 C . Find the average heat transfer coefficient associated with the flow of water . Mass flow rate is 0.25 Kg/ s and Cp = 4.178 KJ/Kg.Karrow_forward

- A crossflow heat exchanger uses oil (Cp =2.1 kJ/kg ·oC) in the tube bank withan entering temperature of 100oC. The flow rate of oil is 1.2 kg/s. Water flowsacross the unfinned tubes and is heated from 20 to 50oC with a flow rate of0.6 kg/s. If the overall heat-transfer coefficient is 250 W/m2 ·oC, calculate thearea required for the heat exchanger using LMTD method.arrow_forward1. A long thin-walled double-pipe heat exchanger with tube and shell diameters of 1.0 cm and 2.5 cm, respectively, is used to condense refrigerant-134a by water at 20 0C. The refrigerant flows through the tube, with a convection heat transfer coefficient of 5000 W/m2 K. Water flows through the shell at a rate of 0.3 kg/s. Determine the overall heat transfer coefficient of this heat exchanger. If a 2-mm-thick layer of limestone (k = 1.3 W/m K) forms on the outer surface of the inner tube what will be new overall heat transfer coefficientarrow_forwardIn order to cool a mass flow rate of 55 Kg/h of air (cp = 1060 J/KgoC) at 300o C, it is passed through the tube side of a counter flow heat exchanger with a length of 2 m and 2.54 cm tube outer diameter. Thecooling water, (cp = 4182 J/Kg o C and ρ = 1000 Kg/m3 ), enters the heat exchanger at a temperature of 30o C with a volume flow rate of 0.6 Litre/min. If the overall heat transfer coefficient, U, is 5.83 W/m2oC andthe effectiveness of the heat exchanger 60 %, calculate the following:a. The heat transfer rate,b. The exit temperatures of both the water and the air,c- The surface area of the heat exchanger,arrow_forward

- Consider a shell-and-tube water-to-water heat exchanger with identical mass flow rates for both the hot- and cold-water streams. Now the mass flow rate of the cold water is reduced by half. Will the effectiveness of this heat exchanger increase, decrease, or remain the same as a result of this modification? Explain. Assume the overall heat transfer coefficient and the inlet temperatures remain the same.arrow_forwardQUESTION 8 Cold water (C, = 4180 J/kg.°C) enters the tubes of a heat exchanger with 2-shell passes and 20 tube passes at 20 °C at a rate of 3 kg/s, while hot oil (C, = 2200 J/kg.°C) enters the shell at 130 °C at the same mass flow rate and leaves at 60°C. If the overall heat transfer coefficient based on the outer surface of the tube is 300 W/m².°C, determine; i. the rate of heat transfer and ii. the heat transfer surface area on the outer side of the tube.arrow_forwardIt is desired to heat 230 kg / h of water from 36 to 94 ºC with oil (Cp = 2.1 kJ / kg ºC) that has an initial temperature of 175 ºC. The oil mass flow is also 230 kg / h. It has a double tube exchanger in parallel, with a total heat transfer coefficient of 570 W / m2 ºC. Calculate the total surface area of the heat exchanger.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY