Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Solve this problem and show all of the work

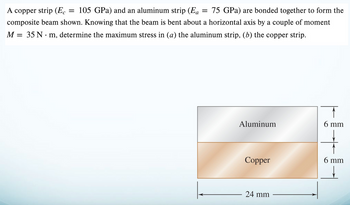

Transcribed Image Text:A copper strip (Ec = 105 GPa) and an aluminum strip (Ea

= 75 GPa) are bonded together to form the

composite beam shown. Knowing that the beam is bent about a horizontal axis by a couple of moment

.

M = 35 N m, determine the maximum stress in (a) the aluminum strip, (b) the copper strip.

Aluminum

6 mm

Copper

6 mm

24 mm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- Need ok answerarrow_forwardThe couple M=129 kip-in. acts in a vertical plane and is applied to a beam oriented as shown. Determine the stress at point A 24 in. 24 in The stress at point A is 2.4 in 24 in. 2.4 in 2.4 in. kslarrow_forwardA steel bar and an aluminum bar are bonded together to form the composite beam shown. The modulus of elasticity for aluminum is 70 GPa and for steel is 200 GPa. Knowing that the beam is bent about a horizontal axis by a couple of moment M= 1500 N·m, determine the maximum stress in (a) the aluminum, (b) the steel.arrow_forward

- A chain link with a circular cross section of diameter d = 12 mm is subjected to the forces exerted by neighboring links, as illustrated below. Determine: 1) the maximum tensile stress and maximum compressive stress acting on cross section AA'. 2) the distance between the neutral axis and the centroid of cross section AA'. 4800 N 800 N - AA'arrow_forwardTwo equal and opposite couples of magnitude M = 23 kN•m are applied to the channel-shaped beam AB. The cross-section is shown, with the length of CD as L = 133 mm. Determine the maximum compressive stress in the cross-section. (The result is accurate to one decimal place, in the unit of MPa. Please write down only the absolute value of the final result) M A M' B 180 mm L E D -36 mm 30 mm 30 mmarrow_forwardThe 6 × 12-in. timber beam has been strengthened by bolting to it the steel reinforcement shown. The modulus of elasticity for wood is 1.8 × 106 psi and for steel, 29 × 106 psi. Knowing that the beam is bent about a horizontal axis by a couple of moment M = 458 kip·in., determine the maximum stress in the wood and in the steel. The maximum compressive stress in the block of wood is ksi (include a negative sign). The maximum tensile stress in the steel is ksi.arrow_forward

- A steel pipe and an aluminum pipe are securely bonded together to form the composite beam shown. The modulus of elasticity is 200 GPa for the steel and 70 GPa for the aluminum. Knowing that the composite beam is bent by a couple of moment 500 N?m, determine the maximum stress (a) in the aluminum, (b) in the steel.arrow_forwardThe couple M is applied to a beam of the cross section shown in a plane forming an angle β with the vertical. Determine the stress at (a) point A, (b) point B, (c) point D.arrow_forwardParvinbhaiarrow_forward

- handwritten-solutions, please!arrow_forwardA) Using the ultimate stress found earlier, determine the minimum diameter of post BD required for the post not to fail. B) Using the ultimate stress found earlier, determine the minimum diameter of post CE required for the post not to fail.arrow_forward2. Determine the maximum tensile and compressive stresses acting on section a-a of the curved beam shown. 200 mm 50 nm 50 KN 50 KN 100 mmarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY